- 20

- Feb

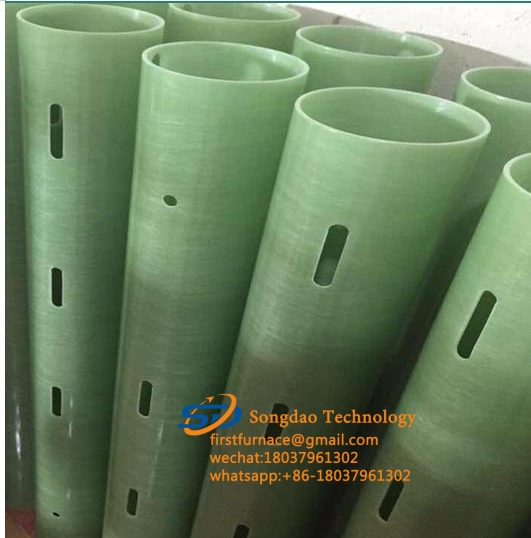

Ipayipi le-epoxy glass fibre winding

Ipayipi le-epoxy glass fibre winding

Ipayipi le-epoxy glass fibre winding lenziwe ngefayibha engaphazamiseki yokujikajika emanzi, ethuthukiswe ngokukhethekile izingxenye zesakhiwo samathuluzi kagesi anamandla amakhulu njengama-reactor, izibambisi zombani, amafuse, ama-transformer, izishintshi zompompi ezilayishiwe, ama-transformer, njll. Imingcele yokusebenza komkhiqizo ukuhlangabezana namazinga e-IEC adingekayo.

Basic parameters of epoxy glass fiber winding pipe:

I-1: I-angle yokuma, i-45~65 (i-angle yokujika ingashintshwa ngokuvumelana nezidingo ezahlukene ukuze kuzuzwe izidingo zokusebenza ezingcono zemishini);

2: Okuqukethwe kwe-Fiber (isilinganiso sesisindo), 70~75%;

3: Ukuminyana, 2.00 g/cm3;

4: Izinga lokumuncwa kwamanzi, ngaphansi kuka-0.03%;

5: I-axial thermal expansion coefficient, 1.8 E-05 1/K;

6: Izinga lokushisa lokushintsha kwengilazi, 110~120 ℃;

7: Ukumelana namakhemikhali. Amafutha amaminerali: kuhle kakhulu;

8: Ncibilikisa futhi hlanza i-asidi: kuhle kakhulu;

9: I-Tensile modulus ye-elasticity, i-axial 14000 MPa;

10: Amandla okuqina; i-axial 280 MPa; circumferential 600 MPa;

11: Amandla okugunda: 150 MPa;

12: Amandla e-Flexural: 350 MPa ekuqondeni kwe-axial;

13: Amandla okucindezela: i-axial 240 MPa;

14: Imvume ehlobene 2-3.2;

I-15: I-Dielectric loss factor 0.003-0.015;

I-16: Umthamo wokukhipha ingxenye ≤5;

17: Dielectric strength: axial 3~6 kV; radial 10~12 kV;

18: Umthelela wombani: 110 KV

19: Ukushaqeka kwefrikhwensi yamandla: 50 KV;

20: Ibanga lokumelana nokushisa: Ibanga B, F, H

21: Ububanzi bangaphakathi>5mm; ububanzi obungaphandle <300mm; ubude <2000mm.

The above data is for reference only. The casing parameters we produce are customized for each customer’s needs

Imikhiqizo yethu ithunyelwe e-United States, Germany, South Korea, Japan, Europe, Russia nakwamanye amazwe.

Our characteristics: According to your requirements, we can design insulating sleeves with various mechanical properties, heat resistance requirements, corrosion resistance grades, color requirements, turning processing (threads/holes/grooves, etc.), and various smoothness of the inner and outer surfaces!