- 20

- Feb

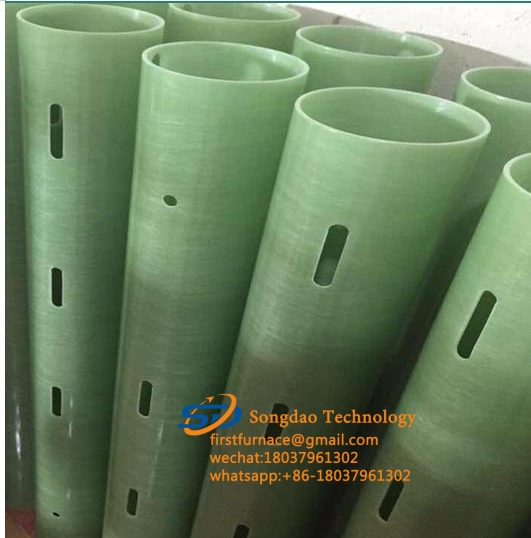

Epoxy khalase faeba matsoelintsoeke phala

Epoxy khalase faeba matsoelintsoeke phala

Epoxy glass fiber winding pipe e entsoe ka faeba e sa sitisoeng ea ho koloba ha metsi, e ntlafalitsoeng ka ho khetheha bakeng sa likarolo tsa sebopeho sa lisebelisoa tsa motlakase tse matla haholo joalo ka li-reactors, li-tights, li-fuse, li-transformer, li-tap-changer, li-transformer joalo-joalo. kopana le maemo a IEC a Hlokahalang.

Basic parameters of epoxy glass fiber winding pipe:

1: Winding angle, 45~65 (leqhubu la matsoelintsoeke le ka fetoloa ho latela litlhoko tse fapaneng ho fihlela litlhoko tse ntle tsa ts’ebetso ea mochini);

2: Likahare tsa fiber (karolelano ea boima), 70~75%;

3: Boima, 2.00 g/cm3;

4: Sekhahla sa ho monya metsi, ka tlase ho 0.03%;

5: Coefficient ea katoloso ea mocheso oa Axial, 1.8 E-05 1/K;

6: Khalase phetoho mocheso, 110~120 ℃;

7: Ho hanyetsa lik’hemik’hale. Oli ea diminerale: e ntle haholo;

8: Hlakola le ho hlapolla acid: e ntle haholo;

9: Tensile modulus ea elasticity, axial 14000 MPa;

10: Matla a thata; axial 280 MPa; circumferential 600 MPa;

11: Matla a ho kuta: 150 MPa;

12: Matla a Flexural: 350 MPa ka tataiso ea axial;

13: Matla a hatellang: axial 240 MPa;

14: Tumello e amanang le eona 2-3.2;

15: Dielectric loss factor 0.003-0.015;

16: Matla a ho ntša karolo e itseng ≤5;

17: Dielectric strength: axial 3~6 kV; radial 10~12 kV;

18: Tšusumetso ea lehalima: 110 KV

19: Tšabo ea maqhubu a matla: 50 KV;

20: Kereiti ea ho hanyetsa mocheso: B, F, H kereiti

21: bophara ba ka hare> 5mm; bophara ba ka ntle <300mm; bolelele <2000mm.

The above data is for reference only. The casing parameters we produce are customized for each customer’s needs

Lihlahisoa tsa rona li rometsoe United States, Jeremane, Korea Boroa, Japane, Europe, Russia le linaheng tse ling.

Our characteristics: According to your requirements, we can design insulating sleeves with various mechanical properties, heat resistance requirements, corrosion resistance grades, color requirements, turning processing (threads/holes/grooves, etc.), and various smoothness of the inner and outer surfaces!