- 20

- Feb

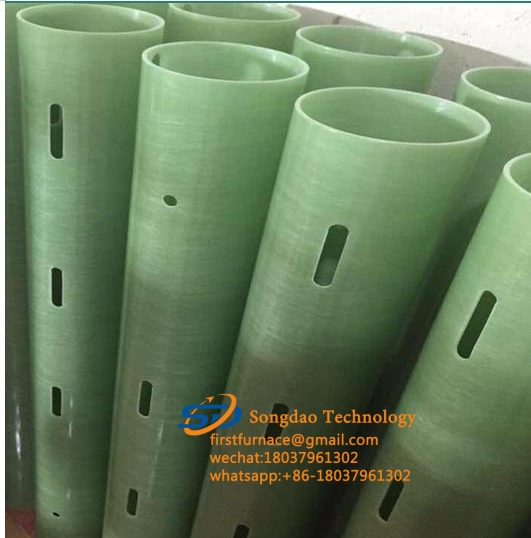

Pipa kaca epoxy fiber winding

Epoxy kaca serat nduwurke tumpukan pipe digawe saka uninterrupted serat udan nduwurke tumpukan, khusus dikembangaké kanggo bagean struktural dhuwur-voltase peralatan electrical kayata reaktor, arresters kilat, sekring, transformer, on-load tunyuk-changers, transformer, etc. Parameter kinerja produk ketemu standar IEC Dibutuhake.

Basic parameters of epoxy glass fiber winding pipe:

1: amba nduwurke tumpukan, 45 ~ 65 ( amba nduwurke tumpukan bisa diatur miturut syarat beda kanggo entuk syarat kinerja mechanical luwih apik);

2: Isi serat (rasio bobot), 70~75%;

3: Kapadhetan, 2.00 g / cm3;

4: Tingkat panyerepan banyu, kurang saka 0.03%;

5: Koefisien ekspansi termal aksial, 1.8 E-05 1/K;

6: Suhu transisi kaca, 110 ~ 120 ℃;

7: resistance kimia. lenga Mineral: apik banget;

8: Solvent lan dilute asam: banget;

9: Modulus elastisitas tarik, aksial 14000 MPa;

10: kekuatan tarik; aksial 280 MPa; circumferential 600 MPa;

11: Kekuwatan geser: 150 MPa;

12: Kekuatan lentur: 350 MPa ing arah aksial;

13: Kekuwatan kompresi: aksial 240 MPa;

14: Permitivitas relatif 2-3.2;

15: Faktor mundhut dielektrik 0.003-0.015;

16: Kapasitas discharge parsial ≤5;

17: Dielectric strength: axial 3~6 kV; radial 10~12 kV;

18: Dampak kilat: 110 KV

19: Kejut frekuensi daya: 50 KV;

20: Kelas tahan panas: kelas B, F, H

21: diameteripun Inner> 5mm; diameteripun njaba <300mm; dawa <2000mm.

The above data is for reference only. The casing parameters we produce are customized for each customer’s needs

Produk kita wis diekspor menyang Amerika Serikat, Jerman, Korea Selatan, Jepang, Eropa, Rusia lan negara liyane.

Our characteristics: According to your requirements, we can design insulating sleeves with various mechanical properties, heat resistance requirements, corrosion resistance grades, color requirements, turning processing (threads/holes/grooves, etc.), and various smoothness of the inner and outer surfaces!