- 08

- Apr

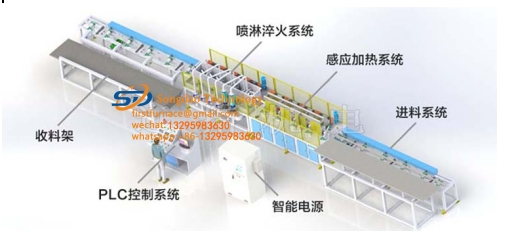

Main technical parameters ntawm round steel quenching thiab tempering ntau lawm kab

Main technical parameters ntawm round steel quenching thiab tempering ntau lawm kab:

1. Fais fab mov system: quenching fais fab mov + tempering fais fab mov

2. Cov zis tawm ib teev yog 0.5-2.5 tons, thiab cov peev txheej ntawm daim ntawv thov yog siab tshaj ø15-ø52mm.

3. Conveying roller table: Lub axis ntawm lub rooj rau cov menyuam thiab lub axis ntawm lub workpiece tsim ib lub kaum sab xis ntawm 18-21 °. Lub workpiece rotates thaum mus rau pem hauv ntej ntawm ib tug tas mus li ceev kom lub cua sov ntau yam. Lub rooj rau cov menyuam nruab nrab ntawm lub qhov cub lub cev yog ua los ntawm 304 tsis-magnetic stainless hlau thiab dej-txias.

4. Roller table grouping: pab pawg pub, pawg sensor thiab pawg tawm yog tswj nws tus kheej, uas yog qhov tsim nyog rau cov cua kub tsis tu ncua tsis ua rau muaj qhov sib txawv ntawm cov khoom ua haujlwm.

5. Kev tswj qhov kub thiab txias: ob qho tib si quenching thiab tempering txais yuav American Leitai infrared thermometer kaw-voj tswj qhov system kom raug tswj qhov kub thiab txias.

6. Muaj lub tshuab computer: lub sijhawm ua haujlwm ntawm lub sijhawm tam sim no ntawm lub xeev ntawm kev ua haujlwm tsis ua haujlwm, qhov chaw ua haujlwm tsis nco qab, khaws cia, luam ntawv, ua txhaum cai, tswb thiab lwm yam haujlwm.

7. Kev hloov hluav taws xob: siv quenching + tempering txoj kev, kev siv hluav taws xob yog 280-320 degrees ib tuj.

8. PLC tsis siv neeg ntse tswj qhov system rau kev sib tshuam ntawm cov khoom siv kho cua sov, “ib qho tseem ceeb pib” ntau lawm yog tsis muaj kev txhawj xeeb.