- 08

- Apr

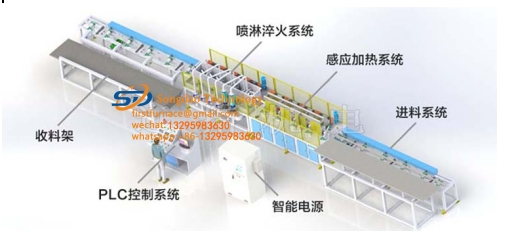

Main technical parameters of round steel quenching and tempering production line

Main technical parameters of round steel quenching and tempering production line:

1. Sistem sumber daya: quenching power supply + tempering power supply

2. Output saben jam 0.5-2.5 ton, lan orane katrangan saka aplikasi ndhuwur ø15-ø52mm.

3. Meja roller conveying: Sumbu meja roller lan sumbu workpiece mbentuk sudut 18-21 °. Bahan kerja muter nalika maju kanthi kecepatan konstan kanggo nggawe pemanasan luwih seragam. Tabel roller ing antarane awak pawon digawe saka stainless steel non-magnetik 304 lan digawe adhem banyu.

4. Panglompokan meja Roller: grup dipakani, grup sensor lan grup discharging sing independen kontrol, kang kondusif kanggo dadi panas tanpa nyebabake longkangan antarane workpieces.

5. Temperatur kontrol loop tertutup: loro quenching lan tempering nggunakake American Leitai thermometer infrared sistem kontrol loop tertutup kanggo ngontrol suhu kanthi akurat.

6. Sistem komputer industri: tampilan nyata-wektu saka negara saiki paramèter apa, workpiece memori parameter, panyimpenan, printing, tampilan fault, weker lan fungsi liyane.

7. Konversi energi: nggunakake metode quenching + tempering, konsumsi daya 280-320 derajat saben ton.

8. PLC automatic intelligent control system for the interface of metal heat treatment equipment, “one-key start” production is worry-free.