- 13

- Jan

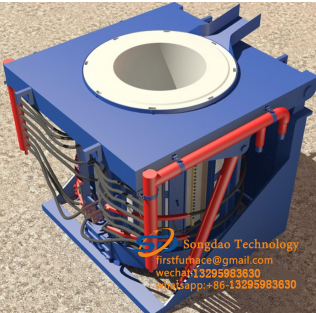

Process of billet induction heating furnace

Process of billet induction heating furnace

The process of the billet indüksiyon ısıtma fırını. At present, in the steel industry, domestic and foreign manufacturers have adopted the continuous casting technology of the billet heating furnace. After the continuous casting machine discharges the billet, the surface temperature of the continuous casting billet drops to about 800 degrees. But the core temperature is about 1050 degrees. Due to the low surface temperature of the billet, it cannot be rolled directly. The user sends the billet to the semi-finished product workshop for processing or puts it in the holding furnace. The average temperature of the continuous casting slab is 925 degrees. If you increase the surface temperature, the temperature will increase from 925 degrees to 1250 degrees. Then we can use a rolling mill to roll.

The surface temperature of the continuous casting slab is lower, and the core temperature is higher. Induction heating is a method that first conducts heat from the surface to the inside. Therefore, using a billet induction heating furnace to increase the surface heat of the billet is the best way to save energy. Making full use of the waste heat of the billet, foreign steel mills have realized this process. Heating from 925 to 1250℃, it needs 45kw-h / if the efficiency of induction heating is 70%, the power consumption is 65kw / hour.

Main features of continuous billet heating furnace:

1. Induction heating equipment: The billet induction heating furnace is divided into a preheating section, a heating section and a soaking section. The steel ingot is charged by the tail of the inductor, passes through three high temperature sections, and is discharged from the heated section. The drum between the induction heaters is made of 304 stainless steel and is cooled by water.

2. Lining: long-life design, sturdy and durable, large pieces of refractory cement.

3. Heating method: induction heating technology, heat is generated inside the billet. There is no preheating time, and the user can start the all-slab induction heating system in a short time.

4. Equipped with 12-pulse power supply and special customized transformer, less harmonic pollution.

Daily maintenance of billet heating furnace:

1. Frequently clean the dust in the power distribution cabinet, set up a special room for the inverter device, and pay attention to cleaning work at all times to prevent insulation failure.

2. Regular inspection and maintenance of the power supply.

Regularly check the fastening bolts, nuts, connectors and other parts.

Check voltage and current regularly to prevent malfunction.

3. Frequently check whether the load connection is intact and whether the insulation is reliable. Always check the cooling water circuit for water shortage or lack of water.

Welcome to contact us at any time, we will share more information about induction furnace heating production line with you.