- 13

- Jan

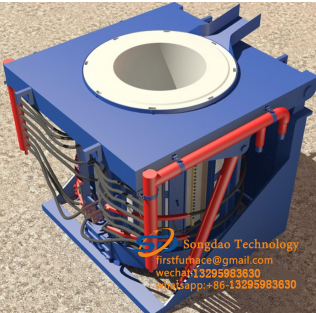

Inqubo ye-billet induction yokushisa isithando somlilo

Inqubo ye-billet induction yokushisa isithando somlilo

Inqubo ye-billet isithando sokushisa sangaphakathi. Njengamanje, embonini yensimbi, abakhiqizi basekhaya nabangaphandle baye bamukela ubuchwepheshe obuqhubekayo bokukhipha isithando somlilo se-billet. Ngemuva kokuthi umshini wokuphonsa oqhubekayo ukhiphe i-billet, izinga lokushisa elingaphezulu le-billet eqhubekayo yokuphonsa lehla lifinyelele cishe kuma-degree angu-800. Kodwa izinga lokushisa eliyisisekelo licishe libe ngama-degree angu-1050. Ngenxa yokushisa okuphansi kwendawo ye-billet, ayikwazi ukugoqwa ngokuqondile. Umsebenzisi uthumela i-billet endaweni yokusebenzela yomkhiqizo osuphelile ukuze icutshungulwe noma ayibeke esithandweni somlilo. Izinga lokushisa elijwayelekile le-casting slab lingama-degree angama-925. Uma ukhuphula izinga lokushisa elingaphezulu, izinga lokushisa lizokhuphuka lisuka ku-925 degrees liye ku-1250 degrees. Ngemva kwalokho singasebenzisa isigayo sokugingqa.

Izinga lokushisa elingaphezulu le-casting slab eliqhubekayo liphansi, futhi izinga lokushisa eliyinhloko liphakeme. Ukushisa kwe-induction kuyindlela eqala ukuqhuba ukushisa kusuka phezulu kuya ngaphakathi. Ngakho-ke, ukusebenzisa i-billet induction yokushisa isithando somlilo ukwandisa ukushisa okungaphezulu kwe-billet kuyindlela engcono kakhulu yokulondoloza amandla. Ukusebenzisa ngokugcwele ukushisa kwemfucuza ye-billet, izigayo zensimbi zangaphandle ziye zaqaphela le nqubo. Ukushisa kusuka ku-925 kuya ku-1250 ℃, kudinga 45kw-h / uma ukusebenza kahle kokushisa kokungeniswa kungu-70%, ukusetshenziswa kwamandla kungu-65kw / ihora.

Izici eziyinhloko zesithando somlilo esiqhubekayo se-billet:

1. Imishini yokushisa ye-induction: Isithando sokushisa se-billet induction sihlukaniswe ngesigaba sokushisa, isigaba sokushisa kanye nesigaba sokucwiliswa. Ingot yensimbi ikhokhiswa umsila we-inductor, idlula ezingxenyeni ezintathu zokushisa okuphezulu, futhi ikhishwe esigabeni esishisayo. Isigubhu esiphakathi kwezifudumezi zokungeniswa senziwa ngensimbi engagqwali engu-304 futhi sipholiswa ngamanzi.

2. I-Lining: idizayini yempilo ende, iqinile futhi ihlala isikhathi eside, izingcezu ezinkulu zikasimende we-refractory.

3. Indlela yokushisa: ubuchwepheshe bokufudumala kwe-induction, ukushisa kukhiqizwa ngaphakathi kwe-billet. Asikho isikhathi sokushisa, futhi umsebenzisi angakwazi ukuqala isistimu yokushisa yokungeniswa kwe-slab ngesikhathi esifushane.

4. Ifakwe ugesi we-12-pulse kanye ne-transformer ekhethekile eyenziwe ngokwezifiso, ukungcola okuncane kwe-harmonic.

Ukugcinwa kwansuku zonke kwesithando sokushisa i-billet:

1. Hlanza njalo uthuli ekhabetheni lokusabalalisa amandla, umise ikamelo elikhethekile ledivayisi ye-inverter, futhi unake umsebenzi wokuhlanza ngaso sonke isikhathi ukuvimbela ukwehluleka kwe-insulation.

2. Ukuhlolwa njalo nokunakekelwa kokuphakelwa kukagesi.

Hlola njalo ama-bolts okubopha, amantongomane, izixhumi nezinye izingxenye.

Hlola i-voltage kanye namandla njalo ukuze uvimbele ukungasebenzi kahle.

3. Njalo hlola ukuthi ingabe ukuxhunywa komthwalo kuqinile yini nokuthi ukufakwa kuthembekile. Njalo hlola isekethe yamanzi okupholisa ukushoda kwamanzi noma ukuntuleka kwamanzi.

Siyakwamukela ukuxhumana nathi nganoma isiphi isikhathi, sizokwabelana nawe ngolwazi oluthe xaxa mayelana nolayini wokukhiqiza wokushisa wesithando sokungeniswa.