- 06

- Oct

Transverse magnetic field induction heating solution treatment of austenitic stainless steel strip

Transverse magnetic field induction heating solution treatment of austenitic stainless steel strip

When the austenitic stainless steel strip is heated by the longitudinal magnetic field, it is a non-magnetic material, so the heating efficiency is low, and it is difficult to quickly heat to the solid solution temperature. Thin strips have higher electrical efficiency when heated by a transverse magnetic field.

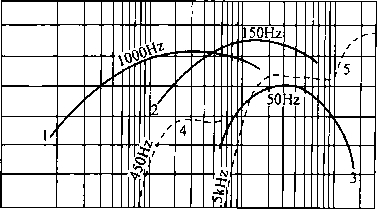

Figure 9-18 shows the comparison of the electrical efficiency of austenitic stainless steel (non-magnetic material) when heated by a transverse magnetic field and a longitudinal magnetic field. In Figure 9-18, the solid line is the transverse magnetic field heating, and the dashed line is the longitudinal magnetic field heating.

It can be seen from Figure 9-18 that the electrical efficiency of the system is close to 80% when the thickness of a 1.0mm non-magnetic steel strip is heated by a 1.0kHz power supply for transverse magnetic field induction heating; while when a 450Hz power supply is used for longitudinal magnetic field induction heating, The electrical efficiency of the system is about 45%, and the difference in electrical efficiency between the two is 35%.

Figure 9-18 Comparison of electrical efficiency when the transverse magnetic field and the longitudinal magnetic field inductively heat non-magnetic materials

1~3—transverse magnetic field heating; 4,5—longitudinal magnetic field heating

It can be seen that transverse magnetic field induction heating is suitable for heating thin strips and non-magnetic materials. The test results show that the most ideal heating steel strip thickness is 0.10~2.0mm. Transverse magnetic field induction heating solution treatment of austenitic stainless steel strip is a new process with good application prospects.