- 08

- Nov

Principle of horizontal and continuous push type induction heating furnace

Principle of horizontal and continuous push type induction heating furnace

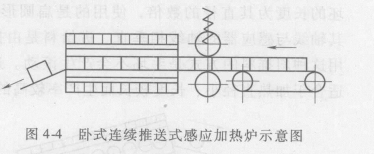

Figure 4-4 is a schematic diagram of a horizontal and continuous push type induction heating furnace. The blanks are not fed sequentially but continuously fed and discharged. In front of the feed end of the inductor is equipped with a guide wheel and a conveyor belt device, so that the blank continuously passes through the inductor to reach the required heating temperature. The material is discharged from the other end of the inductor, and the feeding and discharging speed is calculated and determined according to the heating time required for induction heating and the production rate. This push-type feeding method is suitable for heating smaller diameter blanks, generally the blank diameter is less than 70mm. When the diameter of the blank is larger, the guide rail wears larger in the process of pushing the blank, and its service life is shorter. On the other hand, in this push-type feeding method, because the blanks are pushed through the inductor one by one, when the heating temperature of the blanks is high, adhesion between the blanks and the blanks sometimes occurs. When the length of the blank exceeds 500mm and the number of blanks placed in the inductor does not exceed 2 to 3 pieces, pushing a cold blank into the inductor will increase the power required by the inductor, which is useful for the work of the intermediate frequency power supply Is unfavorable. After the blank enters the inductor for heating for a period of time, the magnetism of the blank disappears, the power required by the inductor is reduced, and the power utilization factor of the equipment is reduced. In the forging and stamping workshops, mechanical shears are usually used for cutting. Due to the abrasion of the cutting blade, the cut of the blank is inclined with flash, and some blanks are bent during the cutting process. Such blanks use push-type The feeding method of the blank passes through the inductor. Even if the length of the inductor is not large, it may be stuck and cause an accident. When the length of the inductor exceeds 2m, the roughness is more likely to be stuck due to poor cutting quality. This push-type induction heating method has another major disadvantage. When the machine stops suddenly, all the blanks stay in the inductor and restart after a period of time. Some of the blanks are too late due to insufficient heating time. It can’t be processed when it is hot, and reheat after cooling down. When the forging equipment is adjusted, a part of the blank cannot be processed. These shortcomings are more obvious for long inductors.