- 06

- Sep

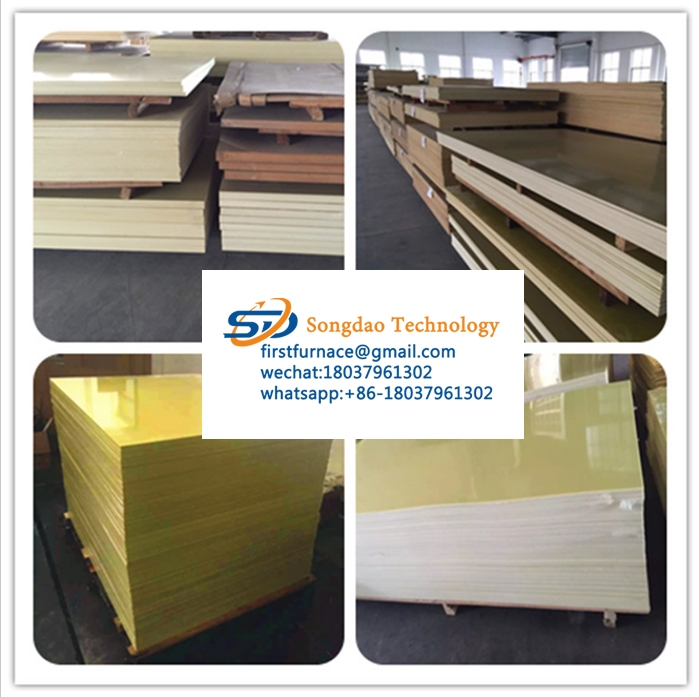

Rufi 3240 epoxy gilashin zane mai zane don lantarki

Rufi 3240 epoxy gilashin zane mai zane don lantarki

3240 allon katako na gilashin epoxy an yi shi da gilashin fiber gilashi wanda aka haɗe da resin epoxy kuma mai zafi da matsi. Samfurin shine 3240. Yana da babban aikin injiniya a matsakaicin zafin jiki da tsayayyen aikin lantarki a babban zafin jiki. Dace da babban-rufi tsarin sassa na inji, lantarki kayan da lantarki, tare da high inji da dielectric Properties, mai kyau zafi juriya da danshi juriya

A. Gabatarwar samfur

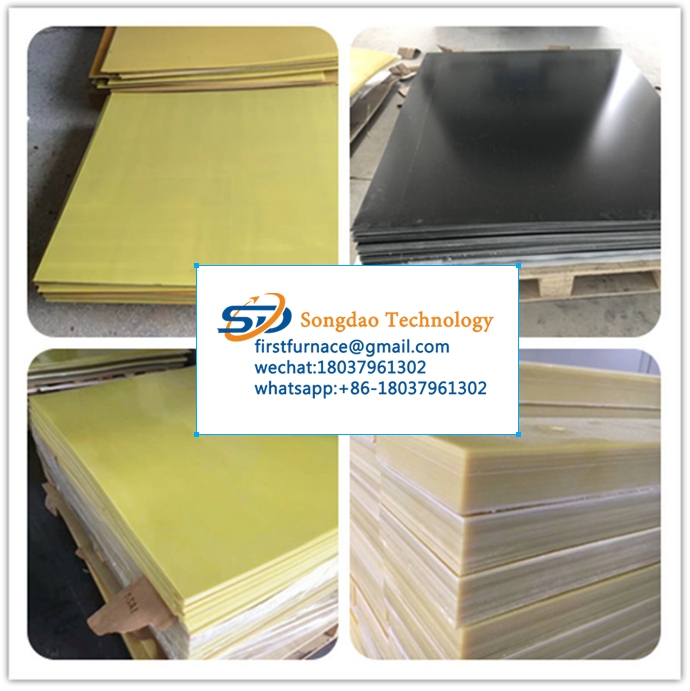

Ruwa na Epoxy gabaɗaya yana nufin mahaɗan polymer na halitta waɗanda ke ɗauke da ƙungiyoyi biyu ko fiye a cikin kwayar. Sai dai fewan kaɗan, yawan danginsu ba su da yawa. Tsarin kwayoyin resin epoxy yana halin ƙungiyar epoxy mai aiki a cikin sarkar kwayoyin. Ana iya samun rukunin epoxy a ƙarshen, a tsakiya ko a cikin tsarin juzu’i na sarkar kwayoyin. Saboda tsarin kwayoyin yana ƙunshe da ƙungiyoyin epoxy masu aiki, suna iya fuskantar halayen haɗin giciye tare da nau’ikan wakilai masu warkarwa don samar da polymers mara narkewa da rashin ƙarfi tare da tsarin hanyar sadarwa uku. 3240 takardar zanen gilashin epoxy an haɗa shi da mayafin fiber gilashi tare da resin mai zafi mai ƙarfi, samfurin 3240, a cikin manyan kayan aikin injin zafin jiki, kaddarorin lantarki da kwanciyar hankali a yanayin zafi. Ya dace da manyan sassan rufi don injin, kayan lantarki da kayan lantarki, tare da manyan injiniyoyi da kaddarorin dielectric, juriya mai kyau da juriya. Matsayin juriya mai zafi F (digiri 155). 1. Bayani dalla -dalla da kauri: 0.5 ~ 100mm 2. Bayanai na al’ada: 1000mm*2000mm 3. Launi: rawaya 4. Wurin asalin: an samar da shi a cikin gida 5. Nakasa lokacin da aka yi zafi a wani babban zafin jiki na 180 ℃, gabaɗaya ba mai zafi tare da sauran karafa , wanda zai iya haifar da ƙarfe Takardar ta lalace.

B. Halayen aikace -aikacen samfur

1. Siffofi daban -daban, resins daban -daban, wakilai masu warkarwa, da tsarin canzawa na iya kusan dacewa da buƙatun aikace -aikace daban -daban akan fom, kuma kewayon na iya kasancewa daga ƙarancin ɗanɗano zuwa babban daskararre mai narkewa.

2. Magani mai dacewa. Ta amfani da wakilai daban -daban na warkarwa, ana iya warkar da tsarin resin epoxy kusan a zafin jiki na 0 zuwa 180 ° C.

3. Manne mai ƙarfi. Ƙungiyoyin polar hydroxyl na asali da haɗin ether a cikin sarkar kwayoyin resins na epoxy sun sa ya zama mai mannewa ga abubuwa daban -daban. Rushewar resin epoxy yana da rauni yayin da ake warkewa, kuma damuwar cikin da aka samar tana da ƙanƙanta, wanda kuma yana taimakawa haɓaka ƙarfin adhesion.

4. Ƙananan raguwa. Ana aiwatar da martani tsakanin resin epoxy da wakili na warkarwa ta hanyar tarawa kai tsaye ko amsawar polymerization na zobe na ƙungiyar epoxy a cikin resin molecule, kuma babu ruwa ko wasu samfuran da ba a iya canzawa ba. Idan aka kwatanta da sinadarin polyester wanda ba a cika cikawa da resins na phenolic ba, suna nuna raguwa sosai (ƙasa da 2%) yayin warkewa.

5. Kayan aikin inji. Tsarin warkar da epoxy resin yana da kyawawan kaddarorin inji.

C. Siffofin fasaha na samfur

1. Dandalin waje ya zama mai santsi, babu kumfa, dunƙule da fasa.

2. Dubi teburin don kaurin suna da karkacewar halatta

| Standard kauri (mm) | karkacewa | Standard kauri (mm) | karkacewa |

| 0.4 | ± 0.1G | 8.0 | ± 0.72 |

| 0. 5 | 0 ba. 12 | 10.0 | ± 0.82 |

| 0.6 | 0 ba. 13 | 12.0 | ± 0.94 |

| 0.8 | 0 ba. 16 | 14.0 | ± 1.02 |

| 1.0 | 0 ba. 18 | 16.0 | 1 ba. 12 |

| 1.2 | 0 ba. 20 | 20.0 | ± 1.30 |

| 1.6 | 0 ba. 2 | 25.0 | 1 ba. 50 |

| 2.0 | ± 0.28 | 3C.0 | 1 ba. 70 |

| 2. 5 | 0 ba. 33 | 35.0 | ± 1.95 |

| 3.0 | 0 ba. 37 | 40.0 | 2 ba. 10 |

| 4.0 | ± 0.45 | 45.0 | ± 2.30 |

| 5.0 | ± 0.52 | 50.0 | ± 2.45 |

| 5.0 | ± 0.6G | 60.0 | 2 ba. 50 |

| 7.0 | ± 0.67 | 80.0 | ± 2.80 |

| Lura: 1 Za’a iya yin shawarwari akan wasu karkacewar izini tsakanin mai siyarwa da mai siye.

2. Ga waɗanda kaurinsu na ainihi ba ɗaya daga cikin ƙa’idodin da aka fi so aka jera ba, karkacewar da aka ba da izini ya kamata ta zama babban juyi na gaba mafi girma da aka fi son kauri. |

|||

3240 jirgin an yi shi ne da ƙyallen gilashin gilashin da ba shi da alkali wanda aka ƙera shi da reshen epoxy phenolic, gasa da matse mai zafi.

Kwamitin 3240 yana da manyan injiniyoyi da kaddarorin Dielectric, mafi kyawun juriya da juriya mai danshi, kuma yana da ingantaccen aiki, kuma matakin juriya zafi shine matakin B.

Kwamitin 3240 ya dace don amfani azaman rufaffen sassan tsari a cikin injinan lantarki da kayan lantarki, kuma ana iya amfani da shi a cikin yanayi mai danshi da mai mai juyawa. Tare da manyan injiniyoyi da kayan lantarki,

Ana amfani da allon 324 sosai azaman kayan rufewa da abubuwan haɗin gwiwa a cikin janareto, injin, da kayan lantarki. Hakanan ya dace sosai don yanayin matse mai mai canzawa da yanayin zafi.

Halin da ke tsakanin resin epoxy da wakilin maganin da ake amfani da shi ana aiwatar da shi ta hanyar tarawa kai tsaye ko raunin buɗe polymerization na ƙungiyoyin epoxy a cikin ƙwayar resin, kuma babu ruwa ko wasu samfura marasa ƙarfi da aka saki. Idan aka kwatanta da sinadarin polyester wanda ba a cika cikawa da resins na phenolic ba, suna nuna raguwa sosai (ƙasa da 2%) yayin warkewa.