- 06

- Sep

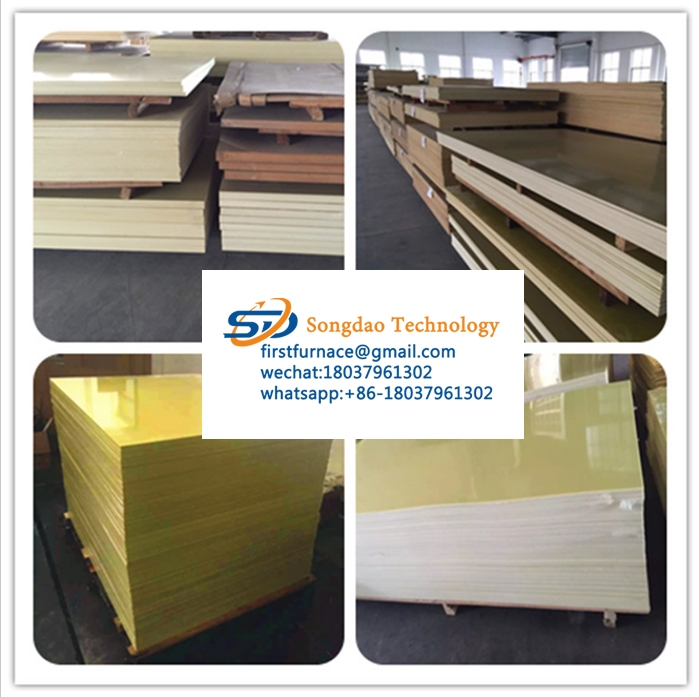

Insulation 3240 epoxy glass cloth board for electrician

Insulation 3240 epoxy glass cloth board for electrician

3240 epoxy glass cloth board is made of glass fiber cloth bonded with epoxy resin and heated and pressurized. The model is 3240. It has high mechanical performance at medium temperature and stable electrical performance at high temperature. Suitable for high-insulation structural parts for machinery, electrical appliances and electronics, with high mechanical and dielectric properties, good heat resistance and moisture resistance

A. Pengenalan produk

Epoxy resins generally refer to organic polymer compounds containing two or more epoxy groups in the molecule. Except for a few, their relative molecular masses are not high. The molecular structure of epoxy resin is characterized by the active epoxy group in the molecular chain. The epoxy group can be located at the end, in the middle or in a cyclic structure of the molecular chain. Because the molecular structure contains active epoxy groups, they can undergo cross-linking reactions with various types of curing agents to form insoluble and infusible polymers with a three-way network structure. 3240 epoxy glass cloth sheet is bonded by a glass fiber cloth with epoxy resin heated pressurized production, model 3240 , in the high temperature mechanical properties, electrical properties and stability at high temperatures. It is suitable for high-insulation structural parts for machinery, electrical appliances and electronics, with high mechanical and dielectric properties, good heat resistance and moisture resistance. Heat resistance grade F ( 155 degrees). 1. Specifications and thickness: 0.5 ~100mm 2. Conventional specifications: 1000mm*2000mm 3. Color: yellow 4. Place of origin: domestically produced 5. Deformation when heated at a high temperature of 180℃ , generally not heated together with other metals, which may cause metal The sheet is deformed.

B. Product application characteristics

1. Various forms, various resins, curing agents, and modifier systems can almost adapt to the requirements of various applications on the form, and the range can be from extremely low viscosity to high melting point solids.

2. Convenient curing. Using various curing agents, the epoxy resin system can be cured almost at a temperature range of 0 to 180°C .

3. Strong adhesion. The inherent polar hydroxyl groups and ether bonds in the molecular chain of epoxy resins make it highly adhesive to various substances. The shrinkage of epoxy resin is low when curing, and the internal stress generated is small, which also helps to improve the adhesion strength.

4. Low shrinkage. The reaction between epoxy resin and curing agent is carried out by direct addition reaction or ring-opening polymerization reaction of epoxy group in resin molecule, and no water or other volatile by-products are released. Compared with unsaturated polyester resins and phenolic resins, they show very low shrinkage (less than 2% ) during curing .

5. Mechanical properties. The cured epoxy resin system has excellent mechanical properties.

C. Product technical parameters

1. The exterior surface should be smooth, free of bubbles, wrinkles and cracks.

2. See the table for nominal thickness and allowable deviation

| Standard thickness (mm) | penyimpangan | Standard thickness (mm) | penyimpangan |

| 0.4 | ± 0.1G | 8.0 | ± 0.72 |

| 0. 5 | ±0. 12 | 10.0 | ± 0.82 |

| 0.6 | ±0. 13 | 12.0 | ± 0.94 |

| 0.8 | ±0. 16 | 14.0 | ± 1.02 |

| 1.0 | ±0. 18 | 16.0 | ±1. 12 |

| 1.2 | ±0. 20 | 20.0 | ± 1.30 |

| 1.6 | ±0. 2 4 | 25.0 | ±1. 50 |

| 2.0 | ± 0.28 | 3C.0 | ±1. 70 |

| 2. 5 | ±0. 33 | 35.0 | ± 1.95 |

| 3.0 | ±0. 37 | 40.0 | ±2. 10 |

| 4.0 | ± 0.45 | 45.0 | ± 2.30 |

| 5.0 | ± 0.52 | 50.0 | ± 2.45 |

| 5.0 | ± 0.6G | 60.0 | ±2. 50 |

| 7.0 | ± 0.67 | 80.0 | ± 2.80 |

| Note: 1 Other allowable deviations can be negotiated between the supplier and the buyer.

2. For those whose nominal thickness is not one of the preferred thicknesses listed , the allowable deviation should be the next larger deviation of the preferred thickness. |

|||

3240 board is made by electrician’s alkali-free glass fiber cloth impregnated with epoxy phenolic resin, baked and hot pressed.

3240 board has higher mechanical and dielectric properties, better heat resistance and moisture resistance, and has good machinability, and the heat resistance grade is B grade.

The 3240 board is suitable for use as insulating structural parts in motors and electrical equipment, and can be used in humid environments and transformer oil. With high mechanical and electrical properties,

324 boards are widely used as insulating materials and components in generators, motors, and electronic appliances. It is also very suitable for transformer oil pressure environment and humidity environment.

The reaction between the epoxy resin and the curing agent used is carried out by direct addition reaction or ring-opening polymerization reaction of epoxy groups in the resin molecule, and no water or other volatile by-products are released. Compared with unsaturated polyester resins and phenolic resins, they show very low shrinkage (less than 2% ) during curing .