- 06

- Sep

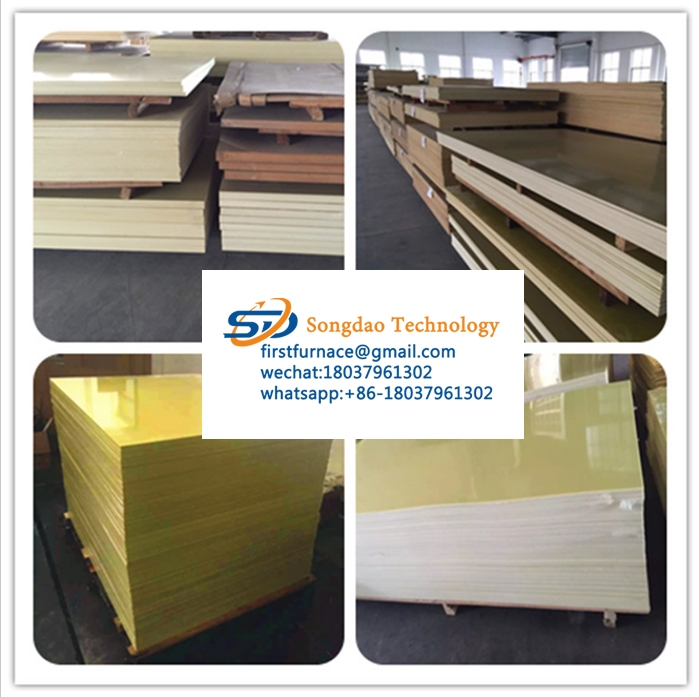

Insulation 3240 epoxy khalase ea lesela bakeng sa motlakase

Insulation 3240 epoxy khalase ea lesela bakeng sa motlakase

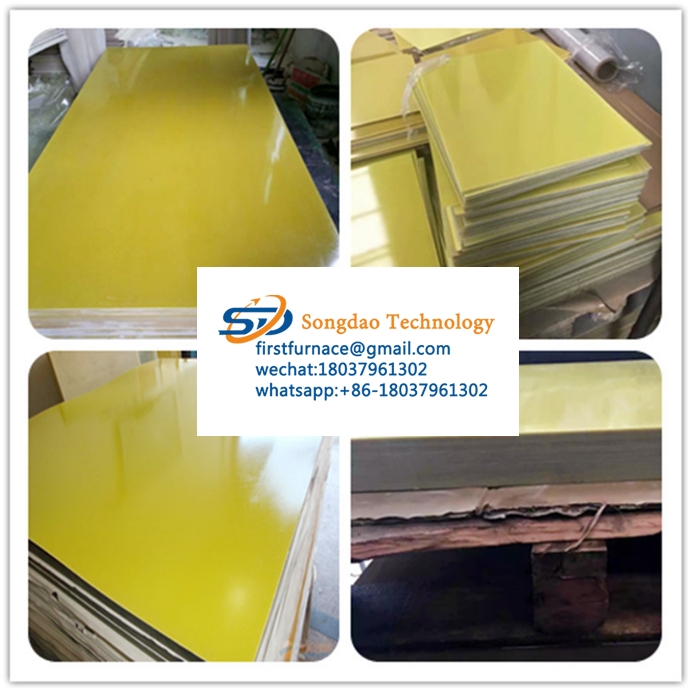

Boto ea lesela la khalase ea 3240 epoxy e entsoe ka lesela la khalase ea fiber le kopantsoeng le epoxy resin mme e futhumetse ebile e hatelletsoe. Moetso ke 3240. E na le ts’ebetso e phahameng ea mochini ka mocheso o mahareng le ts’ebetso e tsitsitseng ea motlakase mochesong o phahameng. E loketse likarolo tse phahameng tsa mochini bakeng sa mechini, lisebelisoa tsa motlakase le lisebelisoa tsa elektroniki, tse nang le thepa e phahameng ea mochini le ea dielectric, ho hanyetsa mocheso hantle le ho hanela mongobo

Kenyelletso ea sehlahisoa

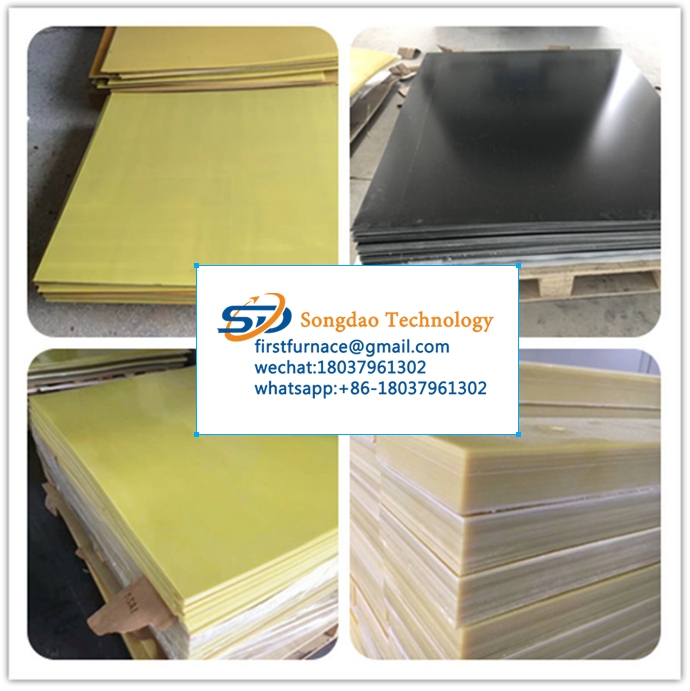

Li-epoxy resin ka kakaretso li bua ka metsoako ea polima e nang le lihlopha tse peli kapa ho feta tsa epoxy ka har’a molek’hule. Ntle le a ‘maloa, limolek’hule tsa tsona tse amanang le limolek’hule ha li phahameng. Sebopeho sa limolek’hule sa epoxy resin se khetholloa ke sehlopha se sebetsang sa epoxy sehlopheng sa limolek’hule. Sehlopha sa epoxy se ka ba qetellong, bohareng kapa mohahong o potolohang oa ketane ea limolek’hule. Hobane sebopeho sa limolek’hule se na le lihlopha tse sebetsang tsa epoxy, li ka etsa liphetoho tse hokahanyang le mefuta e fapaneng ea mahlahana a folisang ho etsa li-polymer tse sa qhibiliheng le tse sa keneng ka sebopeho sa marang-rang. Lesela la lesela la khalase la 3240 epoxy le tlameletsoe ke lesela la khalase le khalase ea epoxy e futhumetseng, ea mofuta oa 3240, mochesong o phahameng oa thepa, thepa ea motlakase le botsitso maemong a phahameng. E loketse likarolo tse phahameng tsa mochini bakeng sa mechini, lisebelisoa tsa motlakase le lisebelisoa tsa elektroniki, tse nang le thepa e phahameng ea mochini le ea dielectric, ho hanyetsa mocheso hantle le ho hanela mongobo. Mocheso ho hanyetsa sehlopheng F (likhato tse 155). 1. Litlhaloso le botenya: 0.5 ~ 100mm 2. Litlhaloso tse tloaelehileng: 1000mm * 2000mm 3. Mmala: o mosehla 4. Sebaka sa tšimoloho: se hlahisoang kahare 5. Phetoho ha e futhumetse mocheso o phahameng oa 180 ℃, ka kakaretso ha e futhumale hammoho le lisebelisoa tse ling , e ka bakang tšepe Leqephe le holofetse.

Litšobotsi tsa ts’ebeliso ea sehlahisoa

1. Mefuta e fapaneng, li-resin tse fapa-fapaneng, lisebelisoa tsa ho folisa le mekhoa ea ho fetola li ka batla li ikamahanya le litlhoko tsa lits’ebetso tse fapaneng ka foromo, mme mefuta e ka ba ho tloha viscosity e tlase haholo ho isa ho tse qhibilihang haholo.

2. Pheko e bonolo. U sebelisa mefuta e fapaneng ea kalafo, epoxy resin system e ka phekoloa hoo e batlang e le mocheso oa 0 ho isa ho 180 ° C.

3. Khomaretsi e matla. Lihlopha tsa tlhaho tsa polar hydroxyl le li-ether bond lihlopheng tsa limolek’hule tsa li-epoxy resin li etsa hore e khomarele lintho tse fapaneng. Ho fokotseha ha epoxy resin ho tlase ha ho phekoloa, mme khatello ea kahare e hlahisoang e nyane, e thusang ho ntlafatsa matla a mamarello.

4. Ho fokotseha ho fokolang. Karabelo lipakeng tsa epoxy lehoakhoa le moetsi oa kalafo e etsoa ka ho kopanya ka kotloloho kapa ho buloa ha lesale ka bongata ba sehlopha sa epoxy ka molek’hule ea lehoakhoa, ‘me ha ho na metsi kapa lihlahisoa tse ling tse sa lokang tse lokolloang. Ha li bapisoa le li-resin tsa polyester tse sa tšeloang le li-phenolic resin, li bonts’a shrinkage e tlase haholo (e ka tlase ho 2%) nakong ea ho folisa.

5. Mechini ea mechini. Sisteme e phekotsoeng ea epoxy resin e na le litšobotsi tse ntle haholo tsa mochini.

C. Lihlahisoa tsa tekheniki ea sehlahisoa

1. bokaholimo ba kantle bo lokela ho ba boreleli, bo se na bubble, makukuno le mapetso.

Sheba tafoleng bakeng sa botenya ba lebitso le ho kheloha ho lumellehang

| Standard botenya (limilimithara) | ho kheloha | Standard botenya (limilimithara) | ho kheloha |

| 0.4 | ± 0.1G | 8.0 | ± 0.72 |

| EA-0. 5 | ± 0. 12 | 10.0 | ± 0.82 |

| 0.6 | ± 0. 13 | 12.0 | ± 0.94 |

| 0.8 | ± 0. 16 | 14.0 | ± 1.02 |

| 1.0 | ± 0. 18 | 16.0 | ± 1. 12 |

| 1.2 | ± 0. 20 | 20.0 | ± 1.30 |

| 1.6 | ± 0. 2 4 | 25.0 | ± 1. 50 |

| 2.0 | ± 0.28 | 3C. 0 | ± 1. 70 |

| EA-2. 5 | ± 0. 33 | 35.0 | ± 1.95 |

| 3.0 | ± 0. 37 | 40.0 | ± 2. 10 |

| 4.0 | ± 0.45 | 45.0 | ± 2.30 |

| 5.0 | ± 0.52 | 50.0 | ± 2.45 |

| 5.0 | ± 0.6G | 60.0 | ± 2. 50 |

| 7.0 | ± 0.67 | 80.0 | ± 2.80 |

| Tlhokomeliso: 1 Ho ka buisanoa ka liphapano tse ling tse lumellehang lipakeng tsa mofani oa thepa le moreki.

2. Bakeng sa bao botenya ba lebitso e seng bo bong ba botenya bo khethiloeng bo thathamisitsoeng, ho kheloha ho lumelloang e lokela ho ba ho kheloha ho latelang ho hoholo ha botenya bo khethiloeng. |

|||

Boto ea 3240 e entsoe ke lesela la khalase ea fiber ea mahala ea alkali e kentsoeng ka lepoxy phenolic resin, e besitsoeng le e chesang e hatisitsoeng.

Boto ea 3240 e na le litšobotsi tse phahameng tsa mochini le tsa dielectric, ho hanyetsa mocheso hantle le ho hanela mongobo, mme e na le ts’ebetso e ntle, mme sehlopheng sa ho hanyetsa mocheso ke B grade.

Boto ea 3240 e loketse ho sebelisoa e le likarolo tse sireletsang mochini ka har’a likoloi le lisebelisoa tsa motlakase, mme e ka sebelisoa libakeng tse mongobo le oli ea transformer. Ka thepa e phahameng ea mochini le ea motlakase,

Liboto tsa 324 li sebelisoa ka bongata e le lisebelisoa tsa ho sirelletsa le likarolo ho lijenereithara, likoloi le lisebelisoa tsa elektroniki. E boetse e loketse tikoloho ea khatello ea oli ea transformer le tikoloho ea mongobo.

Karabelo lipakeng tsa epoxy lehoakhoa le sesebelisoa se phekolang se sebelisitsoeng e etsoa ka ho kopanya ka kotloloho kapa ho buloa ha li-polymerization karabelo ea lihlopha tsa epoxy ka har’a molek’hule ea lehoakhoa, mme ha ho na metsi kapa lihlahisoa tse ling tse sa lokang tse lokolloang. Ha li bapisoa le li-resin tsa polyester tse sa tšeloang le li-phenolic resin, li bonts’a shrinkage e tlase haholo (e ka tlase ho 2%) nakong ea ho folisa.