- 06

- Sep

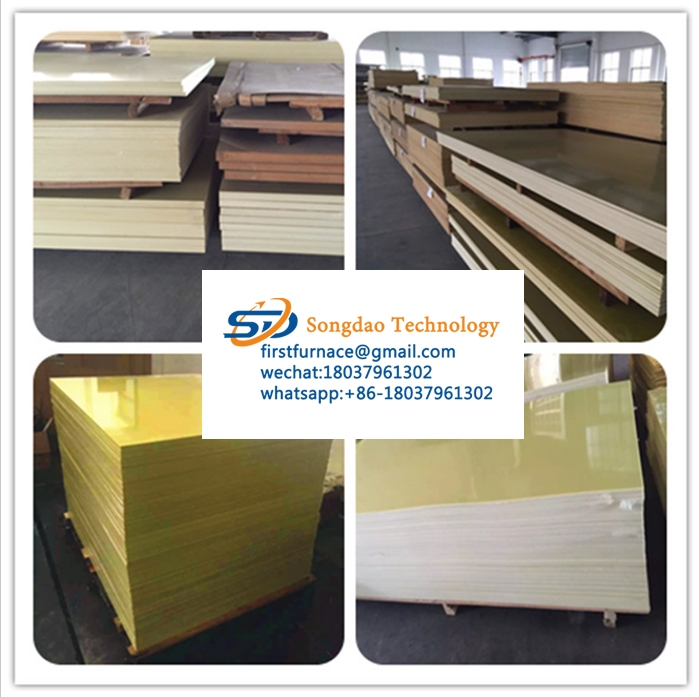

Rwb thaiv tsev 3240 epoxy iav daim ntaub rau hluav taws xob

Rwb thaiv tsev 3240 epoxy iav daim ntaub rau hluav taws xob

3240 epoxy iav daim ntaub board yog ua los ntawm cov iav fiber daim ntaub sib txuas nrog epoxy cob thiab rhaub thiab nias. Tus qauv yog 3240. Nws muaj cov cuab yeej ua haujlwm siab ntawm qhov nruab nrab qhov kub thiab ruaj khov ua haujlwm ntawm qhov kub thiab txias. Haum rau cov txheej txheem rwb thaiv tsev siab rau tshuab, khoom siv hluav taws xob thiab khoom siv hluav taws xob, nrog cov cuab yeej siv siab thiab cov khoom siv hluav taws xob, tiv tshav kub zoo thiab tiv taus ya raws

A. Khoom qhia

Epoxy resins feem ntau xa mus rau cov organic polymer sib txuas uas muaj ob lossis ntau pawg epoxy hauv cov qauv. Tsuas yog qee qhov, lawv cov txheeb ze molecular tsis siab. Cov qauv txheej txheem ntawm epoxy resin yog tus yam ntxwv los ntawm cov pab pawg epoxy nquag hauv cov saw molecular. Cov pab pawg epoxy tuaj yeem nyob ntawm qhov kawg, hauv nruab nrab lossis hauv cov qauv sib txawv ntawm cov saw hlau. Vim tias cov qauv txheej txheem muaj cov pab pawg epoxy nquag, lawv tuaj yeem hla kev sib txuas sib cuam tshuam nrog ntau hom kev kho tus neeg sawv cev kom tsim tau cov tshuaj yaj yeeb uas tsis yaj thiab infusible nrog peb txoj hauv kev network. 3240 epoxy iav daim ntaub ntawv tau sib txuas los ntawm cov iav fiber ntau daim ntaub nrog epoxy resin rhuab nias ntau lawm, qauv 3240, nyob rau hauv qhov kub thiab txias txhua yam khoom, cov khoom siv hluav taws xob thiab ruaj khov ntawm qhov kub. Nws yog qhov tsim nyog rau cov txheej txheem rwb thaiv tsev siab rau tshuab, khoom siv hluav taws xob thiab khoom siv hluav taws xob, nrog cov cuab yeej siv siab thiab cov khoom siv hluav taws xob, tiv tshav kub zoo thiab tiv taus ya raws. Kub tiv taus qib F (155 degrees). 1. Cov lus qhia tshwj xeeb thiab tuab: 0.5 ~ 100mm 2. Cov lus qhia tshwj xeeb: 1000mm*2000mm 3. Xim: daj 4. Qhov chaw ntawm lub hauv paus chiv keeb: tsim hauv tsev 5. Kev hloov pauv thaum kub ntawm 180 ℃, feem ntau tsis sov ua ke nrog lwm cov hlau , uas yuav ua rau hlau Cov ntawv raug deformed.

B. Cov yam ntxwv ntawm daim ntawv thov khoom

1. Ntau yam ntaub ntawv, ntau yam resins, cov neeg ua haujlwm tua kab, thiab cov txheej txheem hloov kho yuav luag yoog raws qhov xav tau ntawm ntau daim ntawv thov ntawm daim ntawv, thiab qhov ntau tuaj yeem yog los ntawm qhov tsis tshua muaj viscosity mus rau qhov siab melting point khib nyiab.

2. Yooj yim kho. Siv ntau yam tshuaj tua kab mob, cov txheej txheem epoxy tuaj yeem kho tau yuav luag ntawm qhov kub ntawm 0 txog 180 ° C.

3. Muaj zog nplaum. Cov pab pawg hydroxyl ncov qaumteb qabteb thiab cov ether bonds hauv cov saw hlau molecular ntawm epoxy resins ua rau nws nplaum rau ntau yam tshuaj. Kev nqaim ntawm epoxy cob yog qhov qis thaum kho, thiab qhov kev nyuab siab sab hauv tsim tawm me me, uas tseem pab txhim kho lub zog ua kom khov.

4. Tsawg shrinkage. Cov tshuaj tiv thaiv ntawm epoxy resin thiab tus neeg sawv cev kho yog ua los ntawm cov tshuaj tiv thaiv ncaj qha ntxiv lossis lub nplhaib-qhib polymerization cov tshuaj tiv thaiv ntawm epoxy pab pawg hauv cov tshuaj molecule, thiab tsis muaj dej lossis lwm yam khoom hloov pauv tau tso tawm. Piv nrog cov polyester uas tsis muaj cov roj hmab thiab cov phenolic resins, lawv qhia tau qis qis qis (tsawg dua 2%) thaum kho.

5. Cov khoom siv dag zog. Cov txheej txheem kho epoxy resin muaj cov cuab yeej zoo heev.

C. Cov khoom siv tsis

1. Sab nrauv sab nrauv yuav tsum du, tsis muaj npuas, tawv nqaij thiab tawg.

2. Saib cov lus rau lub thickness nominal thiab tso cai sib txawv

| Txheem tuab (hli) | kev sib txawv | Txheem tuab (hli) | kev sib txawv |

| 0.4 | ± 0.1G | 8.0 | ± 0.72 |

| 0. Xyoo 5 | ± 0 12 | 10.0 | ± 0.82 |

| 0.6 | ± 0 13 | 12.0 | ± 0.94 |

| 0.8 | ± 0 16 | 14.0 | ± 1.02 |

| 1.0 | ± 0 18 | 16.0 | ± 1 12 |

| 1.2 | ± 0 20 | 20.0 | ± 1.30 |

| 1.6 | ± 0 2 | 25.0 | ± 1 50 |

| 2.0 | ± 0.28 | 3C.0 | ± 1 70 |

| 2. Xyoo 5 | ± 0 33 | 35.0 | ± 1.95 |

| 3.0 | ± 0 37 | 40.0 | ± 2 10 |

| 4.0 | ± 0.45 | 45.0 | ± 2.30 |

| 5.0 | ± 0.52 | 50.0 | ± 2.45 |

| 5.0 | ± 0.6G | 60.0 | ± 2 50 |

| 7.0 | ± 0.67 | 80.0 | ± 2.80 |

| Nco tseg: 1 Lwm qhov kev tso cai sib txawv tuaj yeem sib tham tau ntawm tus neeg xa khoom thiab tus neeg yuav khoom.

2. Rau cov uas nws lub npe tuab tsis yog ib qho ntawm cov tuab uas xav tau teev tseg, qhov kev tso cai sib txawv yuav tsum yog qhov sib txawv loj dua tom ntej ntawm cov tuab uas xav tau. |

|||

3240 lub rooj tsavxwm yog tsim los ntawm kws kho hluav taws xob lub iav tsis muaj alkali iav daim ntaub impregnated nrog epoxy phenolic cob, ci thiab kub nias.

3240 lub rooj tsavxwm muaj cov cuab yeej siv siab dua thiab cov khoom siv hluav taws xob zoo dua qub, tiv tshav kub thiab tiv taus ya raws, thiab muaj lub tshuab ua haujlwm tau zoo, thiab qib tiv tshav kub yog qib B.

3240 lub rooj tsavxwm yog qhov tsim nyog rau siv raws li kev tiv thaiv cov khoom siv hauv cov cav thiab cov khoom siv hluav taws xob, thiab tuaj yeem siv hauv qhov chaw ntub dej thiab hloov roj. Nrog cov cuab yeej siv siab thiab hluav taws xob zoo,

324 cov laug cam tau siv dav ua cov khoom thaiv thiab cov khoom siv hauv cov tshuab hluav taws xob, lub cav, thiab cov khoom siv hluav taws xob. Nws kuj tseem tsim nyog rau kev hloov pauv roj ib puag ncig thiab huab cua ib puag ncig.

Cov tshuaj tiv thaiv ntawm cov tshuaj epoxy cob thiab cov tshuaj tua kab siv yog ua los ntawm cov tshuaj tiv thaiv ncaj qha ntxiv lossis lub nplhaib-qhib polymerization cov tshuaj tiv thaiv ntawm epoxy pawg hauv cov tshuaj molecule, thiab tsis muaj dej lossis lwm yam khoom hloov pauv tau tso tawm. Piv nrog cov polyester uas tsis muaj cov roj hmab thiab cov phenolic resins, lawv qhia tau qis qis qis (tsawg dua 2%) thaum kho.