- 06

- Sep

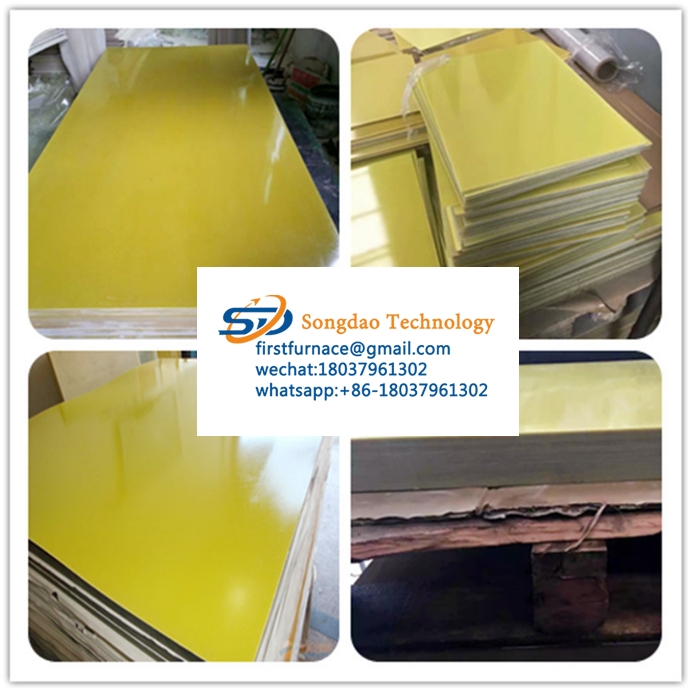

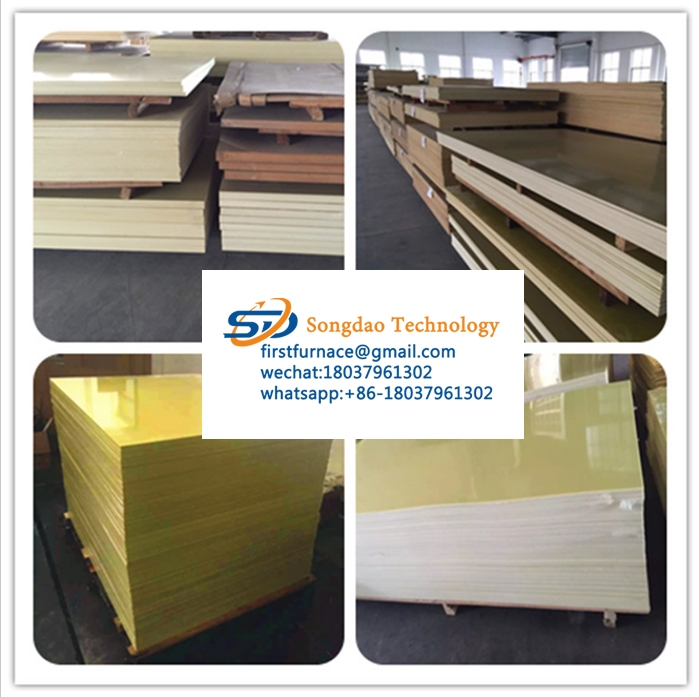

Izinto zokuvala umoya ezingama-3240 epoxy glass board board for electrician

Izinto zokuvala umoya ezingama-3240 epoxy glass board board for electrician

Ibhodi lendwangu yengilazi ye-3240 yenziwe ngengubo yengilazi yefayibha eboshwe nge-epoxy resin futhi iyashiswa futhi icindezelwe. Imodeli ingama-3240. Inokusebenza okuphezulu kwemishini emazingeni okushisa aphakathi nendawo nokusebenza kogesi okuzinzile emazingeni aphezulu okushisa. Ifanele izingxenye zokwakheka eziphakeme kakhulu zemishini, izinto zikagesi kanye ne-elekthronikhi, enezakhiwo eziphezulu zemishini ne-dielectric, ukumelana nokushisa okuhle nokumelana nomswakama

Isingeniso somkhiqizo

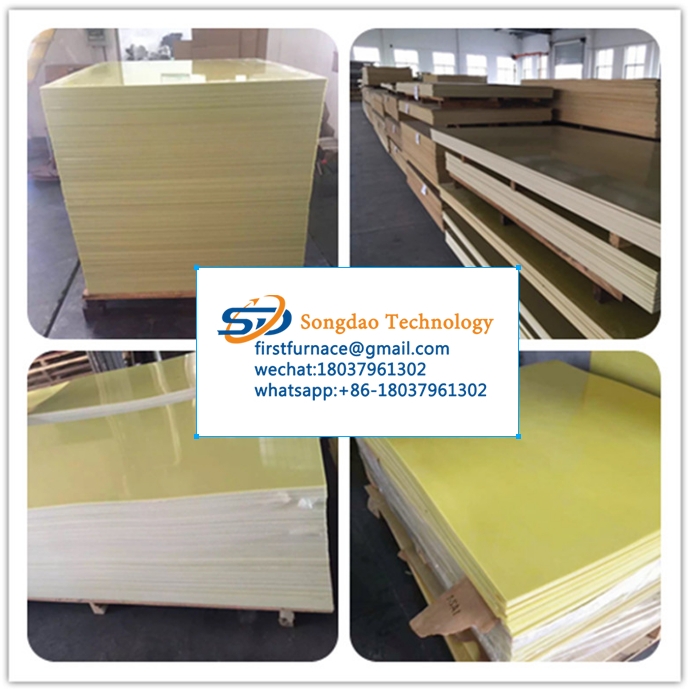

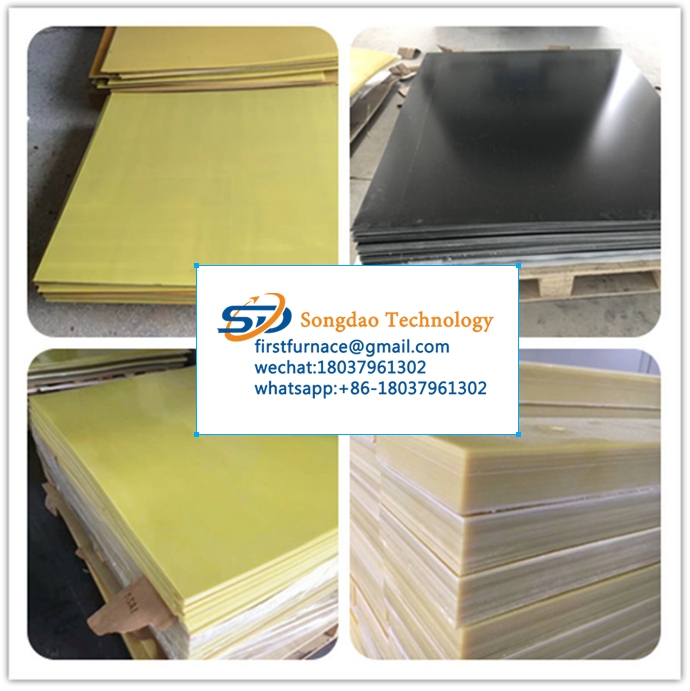

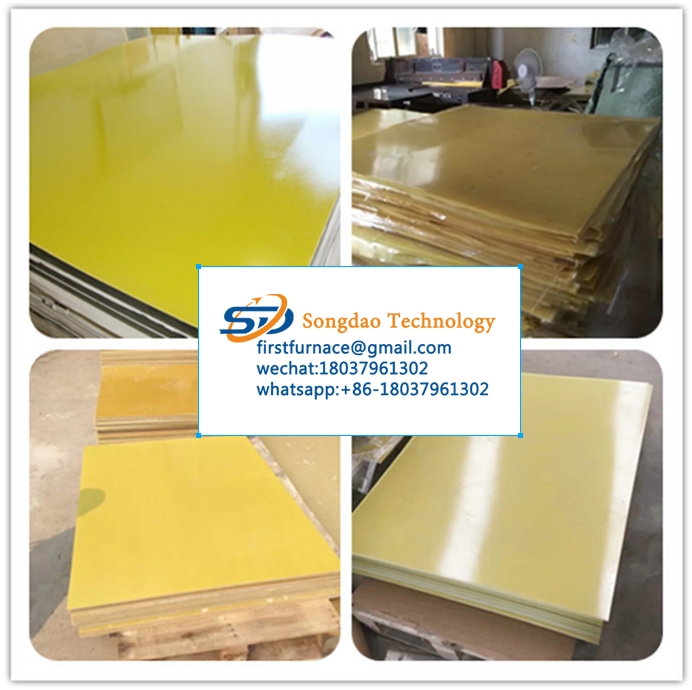

Ama-resin epoxy ngokuvamile abhekisela kumakhemikhali e-organic polymer aqukethe amaqembu amabili noma ngaphezulu epoxy ku-molecule. Ngaphandle kwabambalwa, izihlobo zabo zamangqamuzana ezihlobene aziphakeme. Isakhiwo samangqamuzana se-epoxy resin sibonakala ngeqembu elisebenzayo le-epoxy ochungechungeni lwamangqamuzana. Iqembu le-epoxy lingatholakala ekugcineni, maphakathi noma ngesakhiwo sokujikeleza kochungechunge lwamangqamuzana. Ngoba ukwakheka kwamangqamuzana kuqukethe amaqembu asebenzayo epoxy, angabhekana nokusabela okuxhumanisa nezinhlobo ezahlukahlukene zama-ejenti okwelapha ukwenza ama-polymers angaxazululeki futhi angenakufakwa anezindlela ezintathu zenethiwekhi. 3240 epoxy ingilazi lendwangu ishidi liboshwe ngendwangu yengilazi yengilazi ene-epoxy resin evuthayo yokukhiqiza okucindezelweyo, imodeli 3240, ezindaweni eziphakeme zokushisa zomshini, izakhiwo zikagesi nokuzinza emazingeni okushisa aphezulu. Ifanele izingxenye zokwakheka eziphakeme kakhulu zemishini, izinto zikagesi kanye ne-elekthronikhi, enezakhiwo eziphakeme zemishini ne-dielectric, ukumelana okuhle nokushisa nokumelana nomswakama. Ukushisa ukumelana nebanga F (155 degrees). 1. Imininingwane nobukhulu: 0.5 ~ 100mm 2. Ukucaciswa okujwayelekile: 1000mm * 2000mm 3. Umbala: ophuzi 4. Indawo odabuka kuyo: kukhiqizwa ekhaya 5. Ukuguquguquka lapho kufudunyezwa ekushiseni okuphezulu okungu-180 ℃, ngokuvamile akufudunyeki nezinye izinsimbi , okungadala insimbi Ishidi likhubazekile.

B. Izici zokufaka umkhiqizo

1. Izinhlobo ezahlukahlukene, izinhlaka ezahlukahlukene, ama-ejenti aphilisayo, kanye nezinhlelo zokuguqula kungacishe kuvumelane nezidingo zezicelo ezahlukahlukene kwifomu, futhi ububanzi bungaba kusuka kusiscosity esiphansi ngokweqile kuya kokuqina okuphezulu okuncibilika.

2. Ukwelapha okulula. Usebenzisa ama-ejenti ahlukahlukene aphulukisayo, uhlelo lwe-epoxy resin lungalapheka cishe ebangeni lokushisa elingu-0 kuye ku-180 ° C.

3. Ukunamathela okuqinile. Amaqembu aphethwe yi-polar hydroxyl kanye nezibopho ze-ether ochungechungeni lwamangqamuzana ezinhlaka ze-epoxy zikwenza kube ukunamathela kakhulu ezintweni ezahlukahlukene. Ukuncipha kwe-epoxy resin kuphansi lapho welapha, futhi ukucindezela kwangaphakathi okwenziwe kuncane, okusiza nokwenza ngcono amandla wokubambelela.

4. Ukuncipha okuphansi. Ukusabela phakathi kwe-epoxy resin ne-agent ephulukisayo kwenziwa ngokusabela okuqondile okuqondile noma ukuvulwa kokuvulwa kwe-polymerization kweqembu le-epoxy ku-molecule ye-resin, futhi awekho amanzi noma eminye imikhiqizo evela ezintekenteke ekhishwayo. Uma kuqhathaniswa nezinhlayiya ze-polyester ezingasetshenziswanga nama-phenolic resins, akhombisa ukuncipha okuphansi kakhulu (ngaphansi kuka-2%) ngesikhathi sokuphulukiswa.

5. Izakhiwo zemishini. I-epoxy resin system ephulukisiwe inezakhiwo ezinhle kakhulu zomshini.

C. Imingcele yezobuchwepheshe yomkhiqizo

1. Ingaphandle langaphandle kufanele libushelelezi, lingabi namabhamuza, imibimbi nemifantu.

2. Bheka ithebula ngobukhulu bokuphambuka nokuphambuka okuvumelekile

| Ukujiya Standard (mm) | ukuphambuka | Ukujiya Standard (mm) | ukuphambuka |

| 0.4 | ± 0.1G | 8.0 | ± 0.72 |

| 0. 5 | ± 0. 12 | 10.0 | ± 0.82 |

| 0.6 | ± 0. 13 | 12.0 | ± 0.94 |

| 0.8 | ± 0. 16 | 14.0 | ± 1.02 |

| 1.0 | ± 0. 18 | 16.0 | ± 1. 12 |

| 1.2 | ± 0. 20 | 20.0 | ± 1.30 |

| 1.6 | ± 0. 2 4 | 25.0 | ± 1. 50 |

| 2.0 | ± 0.28 | 3C.0 | ± 1. 70 |

| 2. 5 | ± 0. 33 | 35.0 | ± 1.95 |

| 3.0 | ± 0. 37 | 40.0 | ± 2. 10 |

| 4.0 | ± 0.45 | 45.0 | ± 2.30 |

| 5.0 | ± 0.52 | 50.0 | ± 2.45 |

| 5.0 | ± 0.6G | 60.0 | ± 2. 50 |

| 7.0 | ± 0.67 | 80.0 | ± 2.80 |

| Qaphela: 1 Okunye ukuphambuka okuvumelekile kungaxoxiswana ngakho phakathi komphakeli nomthengi.

2. Kulabo abanobukhulu bokuzibiza okungebona obunye bosayizi obuthandwayo obufakwe kuhlu, ukuphambuka okuvumelekile kufanele kube ukuphambuka okukhulu okulandelayo kobukhulu obuthandwayo. |

|||

Ibhodi le-3240 lenziwa ngendwangu kagesi yengilazi engena-alkali efakwe i-resin epoxy phenolic, ebhakwe futhi ishisiwe.

Ibhodi le-3240 linezakhiwo eziphakeme zemishini nezidielectric, ukumelana kangcono nokushisa nokumelana nomswakama, futhi linokusebenziseka okuhle, futhi ibanga lokumelana nokushisa iBanga lika-B.

Ibhodi le-3240 lilungele ukusetshenziswa njengezingxenye zokuvikela izakhiwo ezimotweni nasemishini kagesi, futhi lingasetshenziswa ezindaweni ezinomswakama nakuwoyela we-transformer. Ngezici eziphakeme zemishini nezikagesi,

Amabhodi angama-324 asetshenziswa kabanzi njengezinto zokuvikela izinto nezinto ezikhiqiza ugesi, izinjini, nezinto zikagesi. Ibuye ilungele kakhulu imvelo yengcindezi kawoyela kanye nemvelo yomswakama.

Ukusabela phakathi kwe-epoxy resin kanye ne-ejenti ephulukisayo esetshenziswayo kwenziwa ngokufaka okuqondile ngqo noma ukuvulwa kwendandatho kokuphendula kwamaqembu epoxy ku-molecule ye-resin, futhi awekho amanzi noma eminye imikhiqizo evela ezintekenteke ekhishwayo. Uma kuqhathaniswa nezinhlayiya ze-polyester ezingasetshenziswanga nama-phenolic resins, akhombisa ukuncipha okuphansi kakhulu (ngaphansi kuka-2%) ngesikhathi sokuphulukiswa.