- 06

- Sep

Nadiifinta 3240 guddiga maro galaas epoxy for koronto yaqaan

Nadiifinta 3240 guddiga maro galaas epoxy for koronto yaqaan

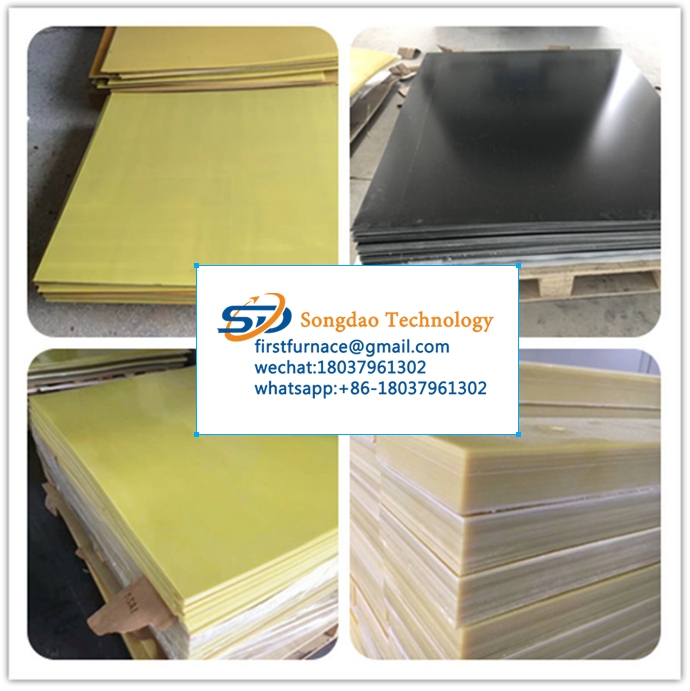

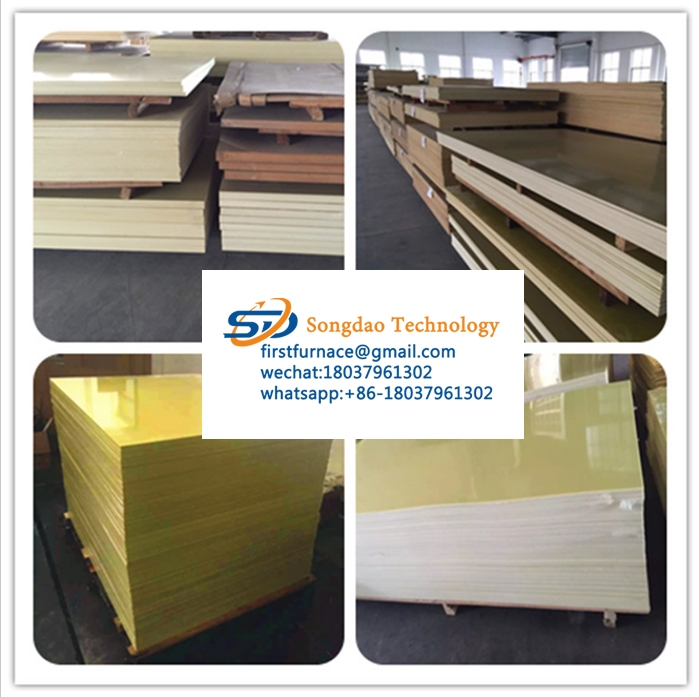

3240 guddiga maro dhalada epoxy waxay ka samaysan tahay maro fiber galaas ah oo ku xiran cusbi epoxy ah oo kululaynaya oo cadaadis saaray. Tusaaluhu waa 3240. Waxay leedahay waxqabad farsamo sare heerkulka dhexe iyo waxqabadka korontada oo deggan heerkulka sare. Ku habboon qaybaha dhismaha-dahaarka sare ee mashiinnada, qalabka korontada iyo elektiroonigga, oo leh farsamooyin sare iyo guryaha korantada, iska-caabbinta kuleylka wanaagsan iyo iska-caabbinta qoyaanka

A. Hordhac alaab

Rinjiga Epoxy wuxuu guud ahaan tixraacayaa xeryahooda polymer -ka dabiiciga ah oo ay ku jiraan laba ama in ka badan kooxaha epoxy ee molecule -ka. In yar mooyaane, tirada kiimikooyinkooda qaraabada ahi ma sarreeyaan. Qaab -dhismeedka molecular ee cusbi epoxy waxaa lagu gartaa kooxda epoxy firfircoon ee silsiladda molecular. Kooxda epoxy waxay ku yaalliin dhamaadka, dhexda ama qaab dhismeedka meerto ee silsiladda molecular. Sababtoo ah qaab-dhismeedka molecular-ku wuxuu ka kooban yahay kooxo epoxy firfircoon, waxay la kulmi karaan fal-celin isku-xiridda leh noocyo kala duwan oo ah wakiilo daaweynaya si ay u sameeyaan polymers aan la milmi karin oo aan la heli karin oo leh qaab-dhismeed saddex-dhinac ah. 3240 xaashida marada galaaska epoxy waxaa ku xiran maro fiber galaas ah oo leh cusbi epoxy resin kuleyl leh wax soo saar cadaadis leh, moodel 3240, oo ku jira guryaha farsamooyinka heerkulka sare, guryaha korantada iyo xasilloonida heerkulka sare. Waxay ku habboon tahay qaybaha dhismaha-dahaarka sare ee mashiinnada, qalabka korantada iyo elektiroonigga, oo leh astaamo farsamo iyo koronto oo sarreeya, iska caabin kuleyl wanaagsan iyo iska-caabbinta qoyaanka. Heerka iska caabbinta kulaylka F (155 digrii). 1. Tilmaamaha iyo dhumucda: 0.5 ~ 100mm 2. Tilmaamaha caadiga ah: 1000mm*2000mm 3. Midabka: huruud 4. Meesha uu ka soo jeedo: gudaha laga soo saaray 5. Deformation marka lagu kululeeyo heerkul sare oo ah 180 ℃, guud ahaan lama kululayn biraha kale , taas oo sababi karta biraha Warqaddu way xumaatay.

B. Tilmaamaha codsiga badeecada

1. Foomam kala duwan, marooyin kala duwan, wakiilo daaweeya, iyo hababka wax -ka -beddelka ayaa ku dhowaad la qabsan kara shuruudaha dalabyada kala duwan ee foomka, oo kala -duwanaantu waxay noqon kartaa mid aad u hooseysa ilaa heer dhibco dhalaalaya oo sare.

2. Daaweyn habboon. Iyada oo la adeegsanayo wakiilo kala duwan oo wax lagu daweeyo, nidaamka cusbi ee epoxy waxaa lagu daaweyn karaa ku dhawaad heerkulka 0 ilaa 180 ° C.

3. Adhesion xoog leh. Kooxaha hydroxyl -ka dabaysha ku jira iyo xidhmooyinka ether ee silsiladda molecular ee resins epoxy waxay ka dhigaan mid aad ugu dheggan walxaha kala duwan. Hoos -u -dhaca resin epoxy -ku wuu hooseeyaa marka la daaweynayo, iyo walbahaarka gudaha ka dhashay waa yar yahay, kaas oo waliba gacan ka geysanaya hagaajinta xoogga dhegdhegga.

4. Hoos u dhaca. Dareen-celinta u dhaxaysa cusbi epoxy iyo wakiilka dawaynta waxaa lagu sameeyaa falcelin toos ah oo toos ah ama falcelinta furitaanka polymerization ee kooxda epoxy ee molecule resin, oo aan biyo ama alaabo kale oo aan degganayn la sii daayo. Marka la barbardhigo maaddada polyester -ka aan la dhergin iyo reexaanta phenolic, waxay muujiyaan yaraanshaha aadka u hooseeya (in ka yar 2%) inta lagu jiro daaweynta.

5. Guryaha farsamada. Nidaamka cusbi ee bogsaday wuxuu leeyahay sifooyin farsamo oo aad u fiican.

C. Xuduudaha farsamada alaabta

1. Dusha sare waa inay ahaataa mid siman, oo aan lahayn goobooyin, laalaab iyo dildilaacyo.

2. Eeg jadwalka dhumucda magacaaban iyo leexashada la oggol yahay

| Dhumucda caadiga ah (mm) | leexasho | Dhumucda caadiga ah (mm) | leexasho |

| 0.4 | ± 0.1G | 8.0 | ± 0.72 |

| 0. 5 | 0. 12 | 10.0 | ± 0.82 |

| 0.6 | 0. 13 | 12.0 | ± 0.94 |

| 0.8 | 0. 16 | 14.0 | ± 1.02 |

| 1.0 | 0. 18 | 16.0 | 1. 12 |

| 1.2 | 0. 20 | 20.0 | ± 1.30 |

| 1.6 | 0. 2 | 25.0 | 1. 50 |

| 2.0 | ± 0.28 | 3C.0 | 1. 70 |

| 2. 5 | 0. 33 | 35.0 | ± 1.95 |

| 3.0 | 0. 37 | 40.0 | 2. 10 |

| 4.0 | ± 0.45 | 45.0 | ± 2.30 |

| 5.0 | ± 0.52 | 50.0 | ± 2.45 |

| 5.0 | ± 0.6G | 60.0 | 2. 50 |

| 7.0 | ± 0.67 | 80.0 | ± 2.80 |

| Xusuusin: 1 Jeexitaannada kale ee la oggolaan karo ayaa laga wada xaajoon karaa alaab -qeybiyaha iyo iibsadaha.

2. Kuwa dhumucdooda magacaaban aysan ka mid ahayn dhumucyada la doorbiday ee la taxay, leexashada la oggol yahay waa inay noqotaa leexashada weyn ee xigta ee dhumucda la doorbiday. |

|||

3240 loox waxaa sameeya maro fiber galaas oo aan alkali lahayn oo koronto-yaqaanku ku dahaadhay cusbiin phenolic epoxy, la dubay oo cadaadisay kulul.

Boodhka 3240 wuxuu leeyahay sifooyin farsamo iyo dielectric sare, iska caabin kuleyl oo fiican iyo iska caabinta qoyaanka, wuxuuna leeyahay farsamo wanaagsan, iyo darajada caabbinta kuleylka waa darajada B

Boodhka 3240 wuxuu ku habboon yahay in loo isticmaalo sida ku -haynta qaybaha dhismaha ee matoorada iyo qalabka korontada, waxaana loo adeegsan karaa deegaannada qoyan iyo saliidda transformer. Iyada oo leh farsamooyin farsamo iyo koronto oo sarreeya,

324 loox ayaa si weyn loogu adeegsadaa inay yihiin qalab dahaar leh iyo qaybo ka mid ah matoorrada, matoorada, iyo qalabka elektiroonigga ah. Waxa kale oo aad ugu habboon deegaanka cadaadiska saliidda transformer iyo deegaanka huurka.

Dareen-celinta u dhexaysa cusbi epoxy iyo wakiilka dawaynta ee la adeegsado waxaa lagu sameeyaa falcelin toos ah oo toos ah ama falcelinta furitaanka polymerization ee kooxaha epoxy-ga ee molecule-ka cusbada, oo wax biyo ah ama badeecado kale oo aan degganayn lama sii daayo. Marka la barbardhigo maaddada polyester -ka aan la dhergin iyo reexaanta phenolic, waxay muujiyaan yaraanshaha aadka u hooseeya (in ka yar 2%) inta lagu jiro daaweynta.