- 05

- Aug

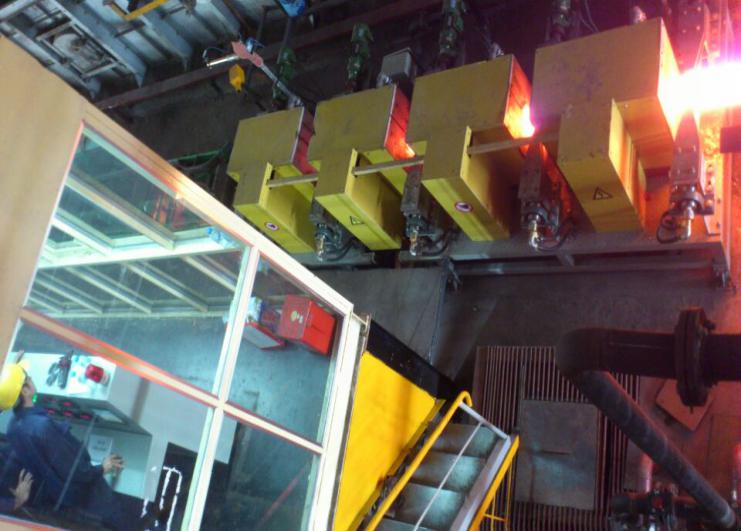

Comparison of induction heating surface hardening and traditional flame heating

Összehasonlítása indukciós fűtőfelület hardening and traditional flame heating

1. Induction heating belongs to the direct heating by the internal heat source, and the heat loss is small, so the heating speed is fast and the thermal efficiency is high.

2. During the heating process, due to the short heating time, there is less oxidation and decarburization on the surface of the parts. Compared with the traditional flame, the scrap rate of the parts is extremely low.

3. After induction heating and quenching, the surface hardness of the parts is high, the core maintains good plasticity and toughness, showing low notches, and the fatigue strength and wear resistance are greatly improved.

4. The induction heating equipment is compact, occupies a small area, and is simple to use (that is, easy to operate).

5. The production process is clean, no high temperature, and good working conditions.

6. Capable of selective heating.

7. The mechanical parts of induction heating surface quenching are less brittle, and at the same time, the mechanical properties of the parts can be improved. The quenching hardness of the steel parts that have also undergone induction heating surface quenching is also higher than that of traditional flame heating.

8. The induction heating equipment can be placed on the processing production line, and the process can be accurately controlled through electrical parameters.

9. Using induction heating and quenching, ordinary carbon structural steel can be used to replace alloy structural steel to make parts without reducing the quality of the parts. Therefore, under certain conditions, it can replace the chemical heat treatment with complex processes.

10. Induction heating is not only used for surface quenching of parts, but also for inner hole quenching of parts, which cannot be achieved by flame heating.