- 05

- Aug

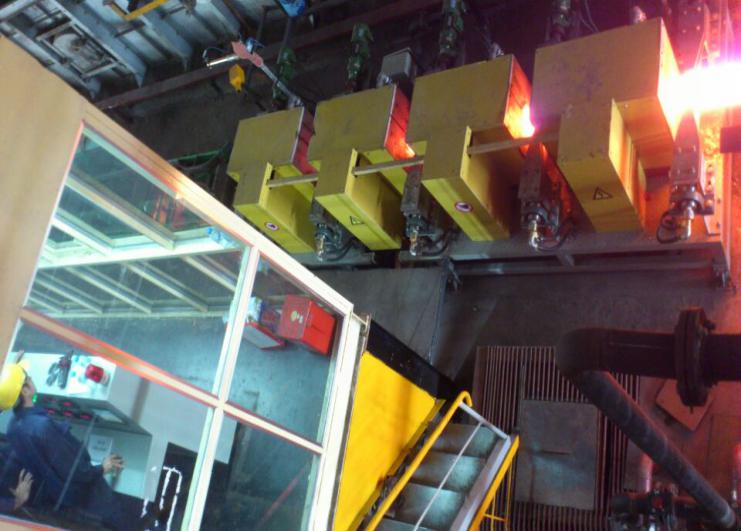

Ntụle nke induction kpo oku elu elu na ikpo ọkụ omenala

Tụnyere nke induction elu kpo oku hardening na omenala ire ọkụ kpo oku

1. Induction kpo oku bụ nke kpo oku kpọmkwem site na isi iyi ọkụ dị n’ime, na ọnwụ okpomọkụ dị ntakịrị, ya mere ọkụ ọkụ na-agba ọsọ ngwa ngwa na arụmọrụ okpomọkụ dị elu.

2. N’oge usoro kpo oku, n’ihi obere oge kpo oku, enweghi oxidation na decarburization n’elu akụkụ. E jiri ya tụnyere ọkụ ọdịnala, ọnụ ọgụgụ mkpofu nke akụkụ ahụ dị oke ala.

3. Mgbe induction kpo oku na quenching, elu ike nke akụkụ dị elu, isi na-ejigide plasticity dị mma na ike siri ike, na-egosi ọkwa dị ala, na ike ọgwụgwụ na iyi mgbochi na-eme ka ọ dịkwuo mma.

4. Ngwa kpo oku induction bụ kọmpat, na-enwe obere mpaghara, ma dị mfe iji (ya bụ, dị mfe iji rụọ ọrụ).

5. Usoro mmepụta dị ọcha, enweghị okpomọkụ dị elu, na ọnọdụ ọrụ dị mma.

6. Ike ịhọrọ kpo oku.

7. The n’ibu akụkụ nke induction kpo oku elu quenching bụ obere kenkuwa, na n’otu oge ahụ, n’ibu Njirimara nke akụkụ nwere ike mma. Ike imenyụ nke akụkụ nchara nke mekwara induction kpo oku elu quenching dịkwa elu karịa nke ọkụ ọkụ ọdịnala.

8. Enwere ike itinye akụrụngwa kpo oku induction na ahịrị mmepụta nhazi, enwere ike ịchịkwa usoro ahụ nke ọma site na paramita eletriki.

9. Iji induction kpo oku na quenching, nkịtị carbon structural ígwè nwere ike iji dochie alloy structural ígwè na-eme akụkụ na-enweghị ibelata àgwà nke akụkụ. Ya mere, n’okpuru ọnọdụ ụfọdụ, ọ nwere ike dochie ọgwụgwọ okpomọkụ nke kemịkal na usoro mgbagwoju anya.

10. A naghị eji ọkụ ọkụ na-ekpo ọkụ na-eme ka ọ bụrụ nanị maka ikpochapụ akụkụ, kamakwa maka imenyụ oghere dị n’ime, nke a na-apụghị ime site na ọkụ ọkụ.