- 15

- Sep

Fanariana tsy tapaka tundish vy nitsonika induction fitaovana

Continuous casting tundish molten steel fitaovana fanorana fanalefahana

1 Famintinana

Tundish molten steel induction heating equipment technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Ny fitaovana fanafanana induction Tundish dia manana ireto toetra manaraka ireto:

(1) Haingam-pandeha fanafanana haingana sy avo herinaratra fanafanana fahombiazana;

(2) Ny karazana sasany koa dia manana fiantraikany mampihetsi-po elektromagnetika, izay mety amin’ny fanesorana ny fampidirana;

(3) Ny mari-pana amin’ny dingana dia mora fehezina, ary ny zava-dehibe indrindra dia ny fanaraha-maso tsara kokoa ny superheat ny vy anidina;

(4) Ny hery fanafanana dia voafetra amin’ny halalin’ny haavon’ny ranon-javatra tundish. Rehefa miangona amin’ny halalin’ny sasany ihany ny vy voarendrika ao anaty tundish, dia afaka mandeha tsara ny fanafanana.

Misy karazana fitaovana fanafanana induction tundish:

(1) Araka ny karazana inductor, dia azo zaraina ho coreless induction fanafanana fitaovana sy cored induction fanafanana fitaovana;

(2) Araka ny firafitry ny inductor, dia azo zaraina ho nitombo karazana fahadisoana sy ny karazana tonelina (groove, hady ritra) induction fanafanana fitaovana;

(3) Araka ny ampahany fanafanana, dia azo zaraina ho fanafanana eo an-toerana sy ny ankapobeny fanafanana.

2 Fanariana tsy tapaka tundish vy voarendrika electromagnetic induction fitaovana fitaovana

2. 1 Tundish electromagnetic induction fanafanana fitaovana mifanaraka amin’ny horizontaly mitohy fanariana milina

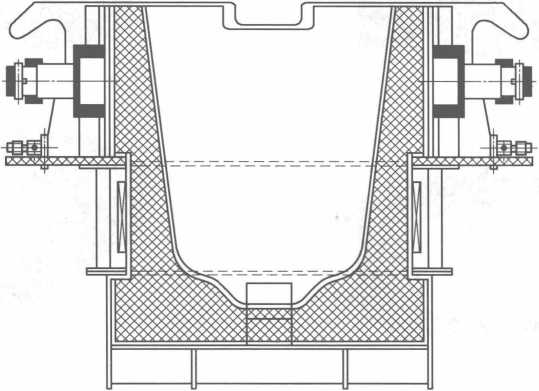

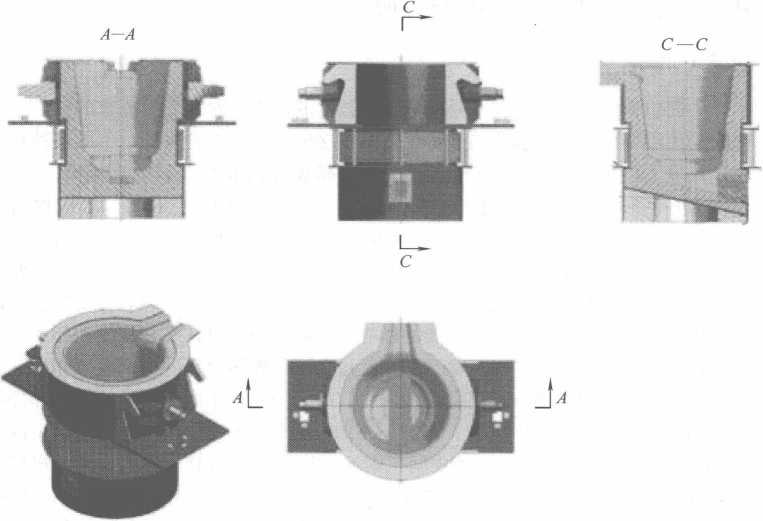

Ny fitaovana fanafanana induction electromagnetic tundish mifanaraka amin’ny milina fanariana mitohy marindrano dia aseho amin’ny sary 10-7.

Hazavaina ankehitriny ny fizotran’ny famokarana orinasa vy tsy misy pentina.

Figure 10-7 Fitaovana fanafanana induction electromagnetika Tundish mifanandrify amin’ny milina fanariana mitohy marindrano

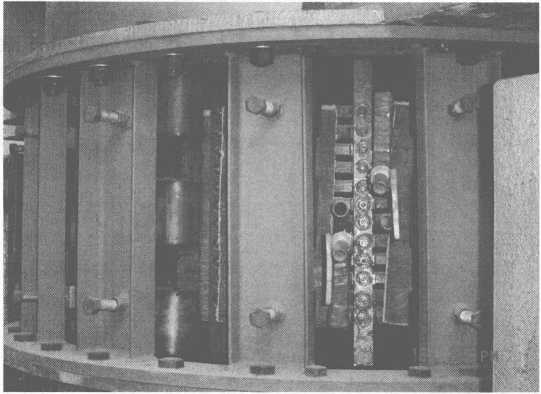

Aorian’ny fanangonana ireo karazana vy tsy misy pentina rehetra dia ampidirina ao anaty lafaoro 5t induction telo avy amin’ny tanky famahanana miaraka amin’ny vano. Aorian’ny fandoroana ny vy amin’ny hafanana ilaina (eo amin’ny 1650 ° C), ny vy voarendrika ao amin’ny lafaoro induction dia arotsaka ao anaty lafaoro, ary avy eo ampiasaina Ny kamiao dia mandatsaka ny vy miendrika ao anaty lafaoro 8t AOD, izay mandalo decarburization, slagging, dephosphorization sy solifara fanesorana, ary ny fanitsiana ny firaka composition (indrindra Cr, Ni), ary avy eo ny vy voarendrika (ny composition sy ny mari-pana mahafeno ny fepetra takiana) Apetraho ao amin’ny ladle ny vy anidina ho any amin’ny ladle ary ampiasao ny vano handraraka. ny vy voarendrika ao amin’ny ladle ao amin’ny ladle ny 8t electromagnetic induction fanafanana fitaovana. Ny ranon-javatra vy tsy misy pentina nafanaina tamin’ny fitehirizana hafanana dia voasintona ary atsipy ao anaty bara boribory amin’ny alàlan’ny milina fanariana mitohy marindrano ary atsofohy amin’ny farafara mangatsiaka amin’ny alàlan’ny famolavolana sy fanosehana. .

Aorian’ny fanangonana ireo karazana vy tsy misy pentina rehetra dia ampidirina ao anaty lafaoro 5t induction telo avy amin’ny tanky famahanana miaraka amin’ny vano. Aorian’ny fandoroana ny vy amin’ny hafanana ilaina (eo amin’ny 1650 ° C), ny vy voarendrika ao amin’ny lafaoro induction dia arotsaka ao anaty lafaoro, ary avy eo ampiasaina Ny kamiao dia mandatsaka ny vy miendrika ao anaty lafaoro 8t AOD, izay mandalo decarburization, slagging, dephosphorization sy solifara fanesorana, ary ny fanitsiana ny firaka composition (indrindra Cr, Ni), ary avy eo ny vy voarendrika (ny composition sy ny mari-pana mahafeno ny fepetra takiana) Apetraho ao amin’ny ladle ny vy anidina ho any amin’ny ladle ary ampiasao ny vano handraraka. ny vy voarendrika ao amin’ny ladle ao amin’ny ladle ny 8t electromagnetic induction fanafanana fitaovana. Ny ranon-javatra vy tsy misy pentina nafanaina tamin’ny fitehirizana hafanana dia voasintona ary atsipy ao anaty bara boribory amin’ny alàlan’ny milina fanariana mitohy marindrano ary atsofohy amin’ny farafara mangatsiaka amin’ny alàlan’ny famolavolana sy fanosehana. .

Ny zavatra ara-batana amin’ny ladle fanafanana induction electromagnetic 8t dia aseho amin’ny sary 10-8.

8t sy 14t tundish electromagnetic induction fitaovana fanamafisam-peo, ny tundish induction fanafanana fitaovana dia afaka hentitra sy araka ny marina mifehy ny mari-pana ny vy narendrika (ny fahadisoana isan-karazany ihany ± 5 ~ 6 ℃), noho izany dia miantoka ny kalitaon’ny billet. Ankoatr’izay, ny fotoana fanitsiana ny mari-pana amin’ny tundish dia azo ampitomboina araka ny tokony ho izy, mampiseho ny vokatra tsara amin’ny fitaovana fanafanana induction.

2. 2 Tundish fitaovana ny induction fanafanana fitaovana ny arc mitohy fanariana milina

Ny fitaovana tundish amin’ny fitaovana fanafanana induction an’ny milina fanariana tsy tapaka dia aseho amin’ny sary 10-9.

Taorian’ny arc billet continuous caster mandray ny electromagnetic induction fanafanana fitaovana tundish, ny mari-pandrefesana dia azo ampidinina (ohatra, dia mety ho

Figure 10-9 Fitaovana Tundish amin’ny fitaovana fanafanana induction amin’ny milina fanariana tsy tapaka

Avy amin’ny 1700 ° C ka hatramin’ny 1650 ° C), izany dia tsy vitan’ny hoe manampy amin’ny fanatsarana ny fiainan’ny lafaoro vy (converter, lafaoro elektrika na lafaoro induction), fa koa manamafy ny mari-pana amin’ny vy miempo amin’ny fanariana tsy tapaka ary miantoka ny kalitaon’ny tsy tapaka. fanariana billet.

Miorina amin’ny teny fampidirana etsy ambony, dia azo heverina fa ny fanariana tsy tapaka tundish magnetic induction fanafanana fitaovana dia vaovao-mitsitsy angovo sy ny tontolo iainana-namana teknolojia. Ny fananganana ity fitaovana ity dia tetik’asa fanovana ara-teknolojia tsara indrindra ho an’ny orinasa metallurgical, ary mendrika ny fampiroboroboana sy fampiasana.

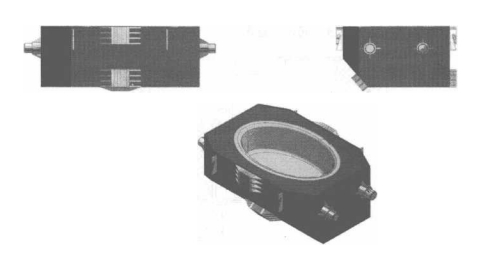

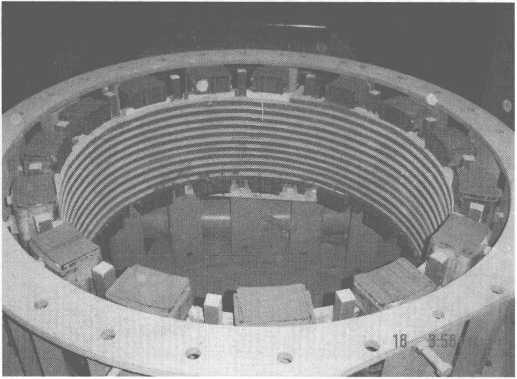

Ny sary 10-10 dia mampiseho ny fitaovana fanafanana induction electromagnetic 16t tundish.

Sary 10-10 16t fitaovana fanafanana induction electromagnetika tundish

Ny sary 10-11 dia diagrama schematic amin’ny tundish ny fitaovana fanafanana induction 14t.

Sary 10-11 diagrama schematic amin’ny tundish amin’ny fitaovana fanafanana induction 14t