- 16

- Sep

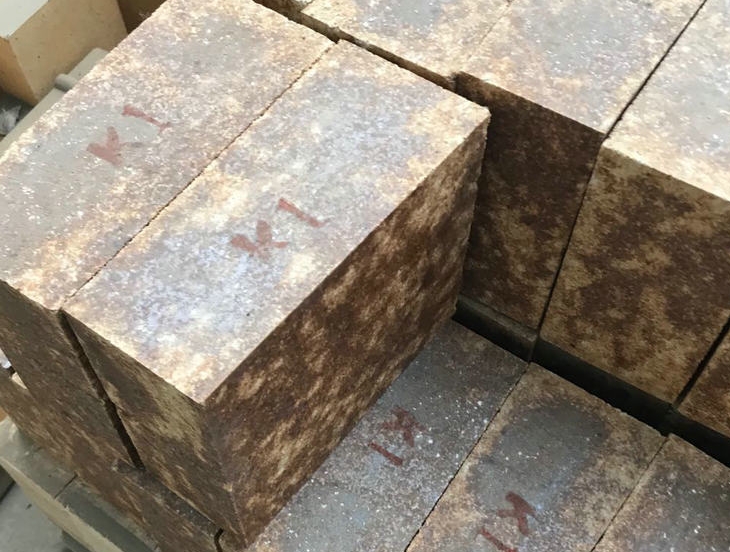

Isitena sesilica

Isitena sesilica

Isitena seSilica sisitena esigxothiweyo esenziwe nge-mullite (3Al2O3.2SiO2) kunye ne-silicon carbide (SiC) njengezona mbiwa ziphambili. Iimpawu zayo ayisiyiyo kuphela ubushushu bokumelana ne-mullite, kodwa kunye nokuqina kokuqina, ukumelana nokubola, kunye nokuqhuba kakuhle kwe-thermal ye-silicon carbide. Xa kwakhiwa iBaosteel ngeminyaka yoo-1980, izinto zokwakha ezaziveliswa zivela kwiNippon Steel, ezazikhangeleka ngathi ziitanki ze-torpedo, zazifana nezitena zangoku ezenziwe nge-silicon. Ngapha koko, yinto eguqulweyo yeemveliso ze-aluminium silicate. Izinto zentsimbi zeladi yitena enezinto ezenziwe ngezitena ezenziwe ngealuminium ephezulu. Kwinkqubela phambili kwezobuchwephesha kumzi-mveliso wentsimbi kunye nentsimbi, ukuze kukhawuleziswe isantya sokwenza intsimbi, isixa esithile seCalcium oxide (CaO) sihamba ekuthiwa kukunyanzelwa kwangaphambili. Ngale ndlela, izinto ezitshintshiweyo etankini kufuneka zimelane nobushushu obuphezulu bentsimbi etyhidiweyo kwaye sixhathise umhlwa we-alkaline owomeleleyo. Ngokucacileyo, izinto eziphezulu zealuminium azinako ukumelana nayo, ke ukongeza isixa esifanelekileyo se-silicon carbide kwizinto eziphezulu zealuminium zenza uhlobo olutsha. Umzi mveliso we-metallurgical uyibiza ngokuba yitena elitshisiweyo le-aluminium silicate edityaniswe ne-silicon carbide.

Ukusebenza kwesitena se-silicon carbide kuvela kwinkqubo yayo. Okokuqala, kufuneka ukhethe i-alumina yebakala ekhethekileyo ene-Al2O3 ephezulu kune-80% kwinto eluhlaza. I-silicon carbide kufuneka ibe nyulu kwaye imfuneko yokuqina kwe-Mohs ikufutshane ne-9.5. Ukukhethwa kwenkampani ye-silicon carbide kungqongqo kakhulu. Olu hlobo lwezimbiwa lunqabile kakhulu. Uninzi lweemveliso zisebenzisa i-SiO2 kunye no-C ukwenza i-SiC kubushushu obuphezulu kwiziko lombane. Izinto ezahlukeneyo zokwenza imveliso ziya kuvelisa umahluko womgangatho. Okwangoku, kwinkqubo yemveliso ye-SiC, i-SiO2 kwizinto ezisetyenziswayo ivela kwisilica yendalo, kwaye i-C ithathwa kwi-coke yamalahle kunye namalahle. I-Petroleum coke, ngokweziphumo zethu zophando, i-silicon carbide edityaniswe ne-petroleum coke kunye ne-SiO2 inezikhombisi eziphezulu malunga nobulukhuni kunye nokunxiba ukuxhathisa, kwaye ilungele ukusetyenziswa njengezitena zesilicon khabhayithi. Izigaba eziphambili zekristale zezitena ezikhutshiweyo ezenziwe ngezi zinto zenziwe ngombala mullite, silicon carbide kunye ne corundum. Ezi zimbiwa zinobulukhuni obuphezulu, obubeka isiseko semveliso eshinyeneyo kunye namandla aphezulu okomelela.

| iprojekthi | Ukuphunyezwa kwesalathiso sezitena zesilica (JC / T 1064 – 2007) | ||

| GM 1650 | GM 1600 | GM 1550 | |

| AL2O3% ≧ | 65 | 63 | 60 |

| Ubuninzi bobunzima / (g / cm3) ≧ | 2.65 | 2.60 | 2.55 |

| I-porosity ebonakalayo% ≦ | 17 | 17 | 19 |

| Ukucinezelwa kwamandla, / MPa ≧ | 85 | 90 | 90 |

| Layisha ubushushu obuthambileyo ℃ ≧ | 1650 | 1600 | 1550 |

| Uzinzo ukothuka Thermal (1100 cooling amanzi okupholisa) amaxesha ≧ | 10 | 10 | 12 |

| Ukumelana nobushushu begumbi / cm3 | 5 | 5 | 5 |