- 29

- Sep

How does the constant velocity universal joint bell shell induction heating furnace production line work?

How does the constant velocity universal joint bell shell hudno sa pagpainit sa induction production line work?

The bell shell of the constant velocity joint has two quenched parts, namely the shank and the inner ballway.

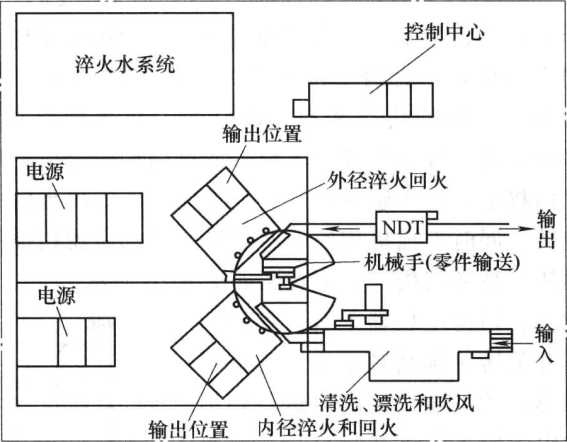

Figure 8-44 shows a constant velocity universal joint bell shell induction heating furnace production line. The working process is: work piece cleaning-inner fairway fire, tempering, rod outer circle and shaft shoulder quenching, tempering-non-destructive inspection (NDT). The inner raceway quenching uses a 300kW, 10kHz solid-state power supply, and the shaft outer circle and shaft shoulder use a 600kW, 10kHz solid-state power supply. Two solid-state power supplies have independent frequency and power, which can meet the needs of more than 60 types of workpieces. The bell-shaped shell is transported from machining to this production line, after spraying cleaning agent cleaning, rinsing with clean water and drying, transporting to the inner ballway quenching position. The quenching position is three stations. There are three spindle clamping components. The sensor is located below the workpiece. The workpiece is placed on the spindle component pneumatically clamped by the manipulator. The spindle component is lowered to accurately position the workpiece above the ballway sensor. Heating It is monitored by the kW-S energy controller. After the ball lanes in the three workpieces are quenched one by one, they are then tempered one by one. The power used is low and the heating time is longer, so that the ball lanes can be uniformly tempered. Then, the bell-shaped shell is sent to the heating position of the outer circle of the uranium rod, a precise process monitor is used, and a servo motor equipped with a step code positioner is used to ensure the precise positioning of the workpiece. An infrared two-color temperature controller is used to monitor the quenching temperature, and a kW·s energy controller is used. In addition, the production line is also equipped with an eddy current non-destructive tester to compare the quenching hardness, depth and area of each workpiece. The test data is programmed to provide statistical process control (SPC) data to determine the actual control level and limit deviation.

Figure 8-44 Constant velocity universal joint bell shell induction heating furnace production line

Another kind of constant velocity universal joint bell shell induction heating furnace production line is shown in Figure 8-45. The working process is to first quench the inner ball channel, and then heat the shaft part after cooling. After cooling, the bell-shaped shell is induction tempered as a whole, and after cooling again, it flows to the next machining process.