- 06

- Nov

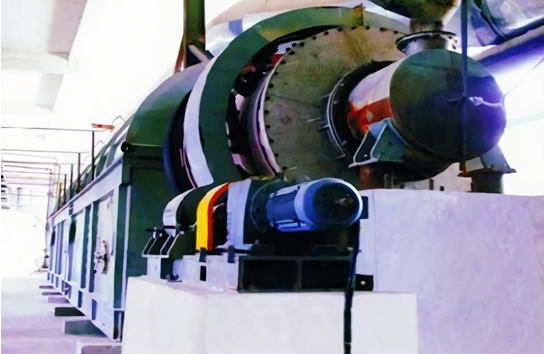

Ib qho tseem ceeb masonry txheej txheem thiab kev tsim kho cov ntsiab lus tseem ceeb ntawm refractory hauv ob sab phlu rau kub roasting rauv

Ib qho tseem ceeb masonry txheej txheem thiab kev tsim kho cov ntsiab lus tseem ceeb ntawm refractory hauv ob sab phlu rau kub roasting rauv

Lub phiaj xwm kev tsim kho refractory ntawm kub roasting rauv lub cev yog sau thiab kev koom ua ke los ntawm refractory cib chaw tsim tshuaj paus.

1. Kev tsim kho ntawm lub refractory castable nyob rau hauv lub rooj tsavxwm faib ntawm lub cub tawg:

(1) Tom qab lub plhaub ntawm lub cub tawg thiab lub qhov cub ntawm lub qhov cub ci tau tsim thiab dhau qhov kev tshuaj xyuas thiab kev lees paub, cov phaj xa tawm refractory castable castable yuav pib. Qhov luaj li cas ntawm txhua qhov yuav tsum tau kuaj xyuas thiab yuav tsum tau muab tso rau hauv cov cua nozzles. Qhov chaw tsim kho yuav tsum tau muab ntxuav thiab lub qhov ncauj yuav tsum raug kaw. Pouring tuaj yeem nqa tau tsuas yog tom qab ntawd.

(2) Ncuav lub teeb yuag thermal rwb thaiv tsev castable ua ntej, thiab tom qab ntawd ncuav lub hnyav-qhov hnyav refractory castable. Cov castables yog tov nrog ib tug quab yuam tov khoom, thiab lub tov khoom yog rinsed nrog dej huv kom paub tseeb tias nws yog huv si thiab tsis muaj impurities.

(3) Cov castable tiav tuaj yeem tsim ncaj qha tom qab ntxiv dej thiab nplawm raws li phau ntawv qhia. Cov castables yuav tsum tau npaj yuav tsum yog proportioned. Ntxiv cov hmoov nplej, hmoov nplej, binders, thiab lwm yam rau hauv cov khoom sib tov, sib tov zoo, thiab tom qab ntawd ntxiv cov dej uas tsim nyog los sib tov rau 2 mus rau 3 feeb ua ntej siv tau.

(4) Qhov sib xyaw castable yuav tsum tau nchuav rau hauv ib zaug hauv 30 feeb.

(5) Castables uas tau teem caij pib yuav tsum tsis txhob muab tso rau hauv kev siv. Thaum lub sij hawm tsim cov castables, ib tug vibrator yuav tsum tau siv los compactly vibrate thaum pouring.

(6) Kev tsim kho ntawm cov castable ntawm lub txaj fluidized yuav tsum ua kom tiav ib zaug, thiab tsis tas yuav khaws cov pob qij txha txuas ntxiv.

(7) Qhov saum npoo ntawm castable txheej yuav tsum tau du thiab tiaj tus. Tom qab 24 teev tom qab ua tiav ntawm kev nchuav, watering thiab curing yuav tsum tau nqa tawm. Lub sijhawm kho tsis pub tsawg tshaj 3 hnub, thiab qhov kub yuav tsum yog 10-25 ° C.

2. Masonry kev tsim kho ntawm refractory cib rau roasting rauv lub cev:

(1) Refractory cib masonry yuav tsum:

1) Refractory cib masonry yuav tsum tau ua los ntawm kneading thiab nias txoj kev (tshwj tsis yog rau tshwj xeeb transformations xws li cib loj), thiab expansion sib koom ua ke loj yuav tsum tau tshwj tseg raws li qhov yuav tsum tau, thiab cov refractory av nkos nyob rau hauv lub sib koom ua ke yuav tsum tau sau nruj nreem thiab tag nrho.

2) Txoj hauj lwm ntawm cov cib refractory thiab qhov loj ntawm cov pob qij txha nthuav dav tuaj yeem hloov kho siv ntoo lossis roj hmab slabs. Lub tiav lawm refractory cib masonry yuav tsum tsis txhob sib tsoo los yog khob rau nws.

3) Thaum lub sij hawm masonry txheej txheem, siv high-concentration refractory mortar rau kev kho mob ua ntej lub expansion sib koom ua ke.

4) Lub refractory cib yog ua tiav los ntawm lub cib cutter. Cov txheej txheem txheej txheem yuav tsum tsis txhob fim rau sab ntawm lub cub tawg thiab lub expansion sib koom ua ke. Qhov ntev ntawm cov txheej txheem cib yuav tsum tsis txhob tsawg tshaj li ib nrab ntawm qhov ntev ntawm cov thawj cib, thiab qhov dav (thickness) kev taw qhia ntawm cov txheej txheem cib yuav tsum tsis txhob tsawg tshaj li qhov dav ntawm thawj cib (Thickness) 2/3 ntawm qhov degree .

5) Thaum tsim cov phab ntsa sib tshuam, xyuas cov qib siab txhua lub sijhawm thiab tsa nws los ntawm txheej txheej. Thaum tawm los yog reworking thiab dismantling, nws yuav tsum tau sab laug raws li ib tug stepped chamfer.

(2) Refractory slurry npaj:

Lub refractory mortar rau metallurgical roasting rauv masonry yuav tsum tau ua los ntawm refractory mortar uas phim cov khoom ntawm refractory cib masonry. Refractory slurry yuav tsum tau npaj los ntawm kev sib xyaw nrog slurry tov khoom. Sim tsis txhob siv tib lub thawv sib xyaw rau refractory slurries ntawm cov khoom sib txawv. Thaum lub refractory slurry yuav tsum tau hloov, cov khoom sib tov thiab lub thawv yuav tsum tau muab yaug nrog dej huv, thiab tom qab ntawd cov khoom yuav tsum tau hloov rau kev sib tov. Lub viscosity ntawm refractory mortar tuaj yeem tswj tau raws li kev tsim kho ntawm qhov chaw, thiab cov tshuaj khib nyiab refractory uas tau tsim los yuav tsum tsis txhob siv.

(3) Rauv phab ntsa refractory cib masonry siv:

1) Lub refractory cib ntawm lub cub tawg yuav tsum tau ua nyob rau hauv seem. Ua ntej txhua ntu ntawm phab ntsa ntawm lub cub tawg yog tsim, ob txheej ntawm graphite hmoov dej iav yuav tsum tau smeared rau ntawm phab ntsa sab hauv ntawm lub cub tawg, thiab tom qab ntawd cov ntaub ntawv rwb thaiv tsev asbestos yuav tsum tau nruj nreem pasted rau ntawm smear txheej, thiab tom qab ntawd lub cub tawg Masonry tsim. ntawm lub teeb yuag refractory bricks thiab hnyav refractory bricks.

2) Txhua ntu ntawm cov phab ntsa rauv yuav tsum tau tsim nrog lub plhaub ntawm lub cub tawg raws li cov masonry sideline, thaum ua kom ntseeg tau qhov flatness ntawm sab hauv ntawm lub cub tawg.

3) Thaum masonry qhov chaw nrog thermal rwb thaiv tsev hauv ob sab phlu, lub teeb yuag refractory bricks yuav tsum tau nteg rau ib tug tej qhov siab ua ntej nteg hnyav-qhov hnyav refractory bricks rau ua hauj lwm hauv ob sab phlu.

4) Thaum tsim lub qhov chaw, txoj hauj lwm ntawm lub qhov qhib yuav tsum tau ua ua ntej, thiab cov phab ntsa ntawm lub qhov cub yuav tsum tau ua kom siab, thiab cov cib kaw ntawm txhua txheej ntawm masonry refractory cib yuav tsum tau muab sib npaug.

(4) Vault brick masonry siv:

1) Raws li txoj kab nruab nrab ntawm lub qhov cub ci, ua ntej tsim cov ko taw-ko taw cib kom qhov siab saum npoo yuav tsum tau khaws cia ntawm tib kab kab rov tav.

2) arch-ko taw cib yog cov cib tshwj xeeb thiab loj loj, yog li txoj kev txhuam tsis haum rau cov masonry. Thaum lub sij hawm tsim kho, qhov saum npoo ntawm refractory bricks yuav tsum tau smeared nrog ib tug tsim nyog tus nqi ntawm refractory av nkos kom lub refractory bricks nyob ib sab muaj ib tug nyob ze thiab zoo kev sib cuag.

3) Tom qab cov pob zeb ko taw ua tiav thiab dhau qhov kev tshuaj xyuas, pib tsim thawj lub nplhaib ntawm cov vault bricks, thiab tom qab ntawd tsim lub nplhaib thib ob tom qab thawj lub nplhaib ntawm lub qhov rooj cib tsim. Cov txheej txheem masonry xav kom qhov sib txawv ntawm cov vault bricks yuav tsum nruj. Qhov luaj li cas ntawm cov pob qij txha expansion yuav tsum sib xws li qhov ua tau.

4) Lub qhov rooj-kaw cib ntawm txhua lub nplhaib ntawm lub vault yuav tsum tau muab sib npaug rau ntawm lub qhov cub tawg, thiab qhov dav ntawm lub qhov rooj-kaw cib yuav tsum tsis pub tsawg dua 7/8 ntawm cov cib qub, thiab lub nplhaib kawg yuav tsum yog. poured nrog castables.

(5) Expansion kev tsim kho:

Txoj hauj lwm thiab qhov loj ntawm qhov tshwj xeeb expansion pob qij txha ntawm lub cub tawg lub cev masonry yuav tsum tau teem raws li tus qauv tsim thiab kev tsim kho. Cov pob qij txha yuav tsum tau muab ntxuav ua ntej sau cov pob qij txha expansion, thiab cov khoom siv refractory ntawm cov khoom tsim yuav tsum tau sau raws li qhov yuav tsum tau ua. Lub filling yuav tsum yog uniform thiab ntom, thiab saum npoo yuav tsum du. .