- 06

- Nov

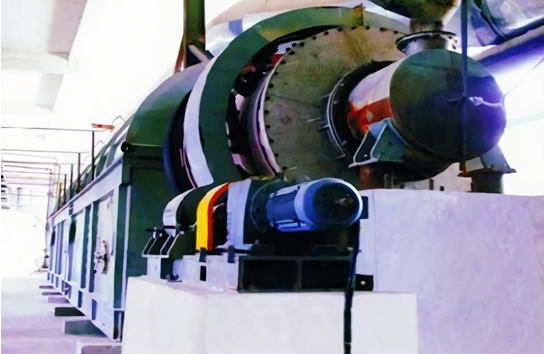

Inkqubo edityanisiweyo yokwakhiwa kwamatye kunye nolwakhiwo lweendawo eziphambili zocweyo olulambathayo kwiziko lokutshisa igolide

Inkqubo edityanisiweyo yokwakhiwa kwamatye kunye nolwakhiwo lweendawo eziphambili zocweyo olulambathayo kwiziko lokutshisa igolide

Isicwangciso sokwakha esichasayo somzimba wesithando somlilo wegolide siqokelelwa kwaye sihlanganiswe ngumenzi wezitena eziphikisayo.

1. Ukwakhiwa okuthululwayo kwe-refractory castable kwibhodi yokuhanjiswa kweziko lokutshisa:

(1) Emva kokuba iqokobhe lesithando somlilo kunye nophahla lweziko lokutshisela lwakhiwe kwaye lwapasiswa uhlolo nolwamkelo, ipleyiti yokuhambisa isitshixo solwakhiwo olunokuqholeka luya kuqaliswa. Ubungakanani benxalenye nganye buya kujongwa kwaye imilomo yomoya edibeneyo iya kufakwa. Indawo yokwakha iya kucocwa kwaye umlomo uya kutywinwa. Ukugalela kunokwenziwa kuphela emva koko.

(2) Galela ukukhanya-ubunzima bokufakelwa kwe-thermal kuqala, kwaye emva koko ugalele i-heavy-weight refractory castable. I-castables ixutywe kunye nomxube onyanzelekileyo, kwaye umxube uhlanjululwe ngamanzi acocekileyo ukuqinisekisa ukuba ucocekile kwaye ukhululekile kwizinto ezingcolileyo.

(3) I-castable egqityiweyo inokwakhiwa ngokuthe ngqo emva kokufaka amanzi kunye nokuxutywa ngokwencwadi yemiyalelo. Izinto ezicatshuliweyo eziza kulungiswa kufuneka zilinganiswe ngokuchanekileyo. Yongeza i-aggregates, i-powders, i-binders, njl. kwi-mixer, xuba kakuhle, uze udibanise umlinganiselo ofanelekileyo wamanzi ukuze udibanise imizuzu emi-2 ukuya kwe-3 ngaphambi kokuba kusetyenziswe ukwakhiwa.

(4) I-castable edibeneyo kufuneka igalelwe ngexesha elinye kwimizuzu engama-30.

(5) Izinto ezifakwayo ebezisetiwe ekuqaleni aziyi kusetyenziswa. Ngexesha lokwakhiwa kwee-castables, i-vibrator kufuneka isetyenziswe ukuxubha ngokudibeneyo ngelixa ugalela.

(6) Ulwakhiwo lwento yokuphosa kwindawo yebhedi enolwelo kufuneka igqitywe ngexesha elinye, kwaye akukho mfuneko yokuba kugcinwe amalungu okwandisa.

7 Iiyure ezingama-24 emva kokugqitywa kokuthulula, ukunkcenkceshela kunye nokunyanga kufuneka kuqhutywe. Ixesha lokunyanga alikho ngaphantsi kweentsuku ezi-3, kwaye ubushushu bokunyanga kufuneka bube yi-10-25 ° C.

2. Ukwakhiwa kweemasonry kwizitena ezinqandayo zokutshisa umzimba wesithando somlilo:

(1) Iimfuno zokwakhiwa kwezitena ezixhathisayo:

1) Ukwakhiwa kwezitena eziphikisayo kufuneka kwakhiwe ngokuxova kunye nokucofa indlela (ngaphandle kweenguqu ezikhethekileyo ezifana nezitena ezinkulu), kunye nobukhulu obudibeneyo bokwandiswa buya kugcinwa njengoko bufunwa, kwaye udaka oluchasayo oludibeneyo luya kuzaliswa ngokuqinileyo kwaye ngokupheleleyo.

I-2) Isikhundla sezitena ezichasayo kunye nobukhulu beendlela zokwandisa zingatshintshwa ngokusebenzisa i-slabs yokhuni okanye i-rubber. Ubume bezitena ezigqityiweyo aziyi kungqubana okanye zibethelwe kuyo.

I-3) Ngexesha lenkqubo yokumisa, sebenzisa i-high-concentration refractory mortar yonyango oludibeneyo ngaphambi kokuba ukudibanisa ukwandiswa kuqiniswe.

4) Izitena eziphikisayo zicutshungulwa ngumsiki wezitena. Umphezulu ocutshungulweyo awuyi kujongana necala lesithando somlilo kunye nokwandiswa ngokubambisana. Ubude besitena esilungisiweyo abuyi kuba ngaphantsi kwesiqingatha sobude besitena sokuqala, kwaye ububanzi (ukutyeba) indlela yesitena esilungisiweyo abuyi kuba ngaphantsi kobubanzi besitena sokuqala ( Ukutyeba) 2/3 yedigri .

5) Xa ukwakhiwa kodonga lwesithando somlilo, khangela ukuphakama kwenqanaba nangaliphi na ixesha kwaye uphakamise umaleko ngoluhlu. Xa ushiya okanye usebenza kwakhona kwaye udilizwa, kufuneka ishiywe njenge-chamfer ene-steped.

(2) Ukulungiswa kodaka olunyibilikayo:

Udaka lwe-refractory lwe-metallurgical roasted masonry yesithando somlilo kufuneka lwenziwe nge-refractory mortar ehambelana nemathiriyeli ye-refractory masonry yezitena. I-refractory slurry kufuneka ilungiswe ngokuxuba kunye nomxube we-slurry. Zama ukungasebenzisi isikhongozeli esifanayo sokuxutywa kodaka lwezixhobo ezahlukeneyo. Xa i-slurry ye-refractory kufuneka itshintshwe, isixhobo sokuxuba kunye nesitya kufuneka sihlanjululwe ngamanzi acocekileyo, kwaye ke into kufuneka ithathelwe indawo yokuxuba. I-viscosity ye-refractory mortar inokulawulwa ngokwemiqathango yokwakhiwa kwendawo, kwaye i-refractory mortar esele isetiwe ekuqaleni ayiyi kusetyenziswa.

(3) Ulwakhiwo lwezitena ezixhathisayo eludongeni lweziko:

1) Izitena eziphikisayo zodonga lwesithando somlilo kufuneka zakhiwe ngamacandelo. Ngaphambi kokuba icandelo ngalinye lodonga lwesithando somlilo lakhiwe, iileya ezimbini zegraphite yomgubo weglasi yamanzi kufuneka ziqatywe kudonga lwangaphakathi lweqokobhe lomlilo, kwaye ibhodi yokugquma i-asbestos kufuneka ifakwe ngokuqinileyo kwi-smear layer, kwaye emva koko i-Masonry yokwakhiwa kwesithando somlilo. yezitena ezikhanyelayo ezilula kunye nezitena ezinzima eziphikisayo.

2) Icandelo ngalinye lodonga lwesithando somlilo kufuneka lakhiwe ngegobolondo lesithando somlilo njengecala le-masonry sideline, ngelixa liqinisekisa ukunyameka kwendawo yangaphakathi yesithando somlilo.

I-3) Xa iindawo ze-masonry kunye ne-thermal insulation lining, izitena ezikhanyelayo ezinobunzima kufuneka zibekwe kumphakamo othile ngaphambi kokubeka izitena ezinzima zobunzima bokusebenza.

4) Xa ukwakhiwa kwendawo yomngxuma, indawo yokuvula umngxuma kufuneka yakhiwe kuqala, kwaye udonga lwesithando somlilo olujikelezileyo luya kwakhiwa phezulu, kwaye izitena zokuvala zomaleko ngamnye wezitena ezinqambileyo ziya kwabiwa ngokulinganayo.

(4) Ulwakhiwo lwezitena zeVault:

I-1) Ngokomgca ophakathi kwesithando somlilo, okokuqala yakha izitena ze-arch-foot ukwenzela ukuba ukuphakama kwendawo kufuneka kugcinwe kumgca othe tye.

I-2) Izitena ze-arch-foot ziyizitena ezikhethekileyo kunye nobukhulu obukhulu, ngoko ke indlela yokuxubha ayifanelekanga kwi-masonry. Ngethuba lokwakha, umphezulu wezitena eziphikisayo kufuneka ucofe ngomlinganiselo ofanelekileyo wodaka oluchasayo ukwenza izitena ezichaseneyo ezikufutshane zibe noqhagamshelwano olusondeleyo kunye oluhle.

3) Emva kokuba izitena ze-arch-foot zigqitywe kwaye zigqithise ukuhlolwa, qalisa ukwakha isangqa sokuqala sezitena ze-vault, kwaye emva koko wakha ikhonkco lesibini emva kokuba kwakhiwa intsimbi yokuqala yezitena zomnyango. Inkqubo yokumisa idinga ukuba i-gap phakathi kwezitena ze-vault kufuneka ibe nzima. Ubungakanani beendawo ezigciniweyo zokwandisa kufuneka zibe zifana ngokusemandleni.

4) Izitena zokuvala umnyango wendandatho nganye ye-vault kufuneka zihanjiswe ngokulinganayo phezu kophahla lwesithando somlilo, kwaye ububanzi bezitena zokuvala umnyango akufanele zibe ngaphantsi kwe-7/8 yezitena zokuqala, kwaye ikhonkco lokugqibela kufuneka libe. zigalelwe ngezinto zokugalela.

(5) Ulwakhiwo oludibeneyo lolwandiso:

Isikhundla kunye nobukhulu beendawo ezigciniweyo zokwandiswa kwesithando somzimba wesithando somlilo kufuneka zibekwe ngokweemfuno zoyilo kunye nokwakhiwa. Amalungu kufuneka ahlambuluke ngaphambi kokuba azalise iindawo zokwandiswa, kunye nezinto ezichasayo zezinto zokuyila kufuneka zizaliswe ngokweemfuno. Ukuzaliswa kufuneka kube yinto efanayo kwaye lukhuni, kwaye umphezulu kufuneka ube lula. .