- 06

- Nov

Inqubo edidiyelwe yokwakhiwa kwamatshe kanye namaphuzu abalulekile wokwakha we-refractory lining yesithando somlilo segolide

Inqubo edidiyelwe yokwakhiwa kwamatshe kanye namaphuzu abalulekile wokwakha we-refractory lining yesithando somlilo segolide

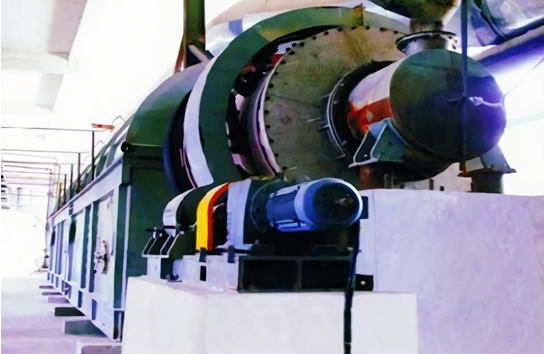

Uhlelo lokwakha oluphikisayo lomzimba wesithando sokushiswa kwegolide luqoqwa futhi luhlanganiswe ngumkhiqizi wezitini eziphikisayo.

1. Ukwakhiwa okuthululwayo kwe-refractory castable ebhodini lokusabalalisa lesithando somlilo:

(1) Ngemva kokuthi igobolondo lesithando somlilo kanye nendawo engaphansi yesithando somlilo sekwakhiwe futhi kwaphasiswa ukuhlolwa nokwamukelwa, ukwakhiwa kwepuleti lokusabalalisa okumbambisayo kuyoqalwa. Usayizi wengxenye ngayinye kufanele uhlolwe futhi ama-nozzles omoya ashunyekiwe azofakwa. Indawo yokwakha izohlanzwa futhi umlomo uvalwe. Ukuthulula kungenziwa kuphela ngemva kwalokho.

(2) Thela i-light-weight thermal insulationable castable first, bese uthela i-heavy-weight refractory castable. Ama-castable ahlanganiswe ne-mixer ephoqelelwe, futhi i-mixer ihlanzwa ngamanzi ahlanzekile ukuze kuqinisekiswe ukuthi ihlanzekile futhi ayinakho ukungcola.

(3) I-castable eqediwe ingakhiwa ngokuqondile ngemva kokwengeza amanzi nokunyakaziswa ngokuvumelana nencwadi yeziqondiso. Ama-castables okufanele alungiselelwe kufanele alinganiswe ngokunembile. Faka ama-aggregate, izimpushana, izibophezelo, njll. ku-mixer, uhlanganise kahle, bese wengeza inani elifanele lamanzi ozowaxuba imizuzu emi-2 kuya kwemi-3 ngaphambi kokuba kusetshenziswe ukwakhiwa.

(4) I-castable exutshwe kufanele ithelwe ngesikhathi esisodwa phakathi nemizuzu engama-30.

(5) Ama-castable asethiwe ekuqaleni ngeke asetshenziswe. Ngesikhathi sokwakhiwa kwama-castable, i-vibrator kufanele isetshenziselwe ukudlidliza okuhlangene ngenkathi kuthululwa.

(6) Ukwakhiwa kwento egandaywayo endaweni yombhede omanzi kufanele kuqedwe ngesikhathi esisodwa, futhi asikho isidingo sokugodla amalunga okunweba.

(7) Ingaphezulu lesendlalelo esisakazwayo liyadingeka ukuze libe bushelelezi futhi libe sicaba. Amahora angama-24 ngemuva kokuphothula ukuthulula, ukuchelela nokwelapha kufanele kwenziwe. Isikhathi sokwelashwa asibi ngaphansi kwezinsuku ezi-3, futhi izinga lokushisa lokuphulukisa kufanele libe ngu-10-25 ° C.

2. Ukwakhiwa kwe-masonry yezitini eziphikisayo zokushisa umzimba wesithando somlilo:

(1) Izidingo zokwakhiwa kwezitini eziphikisayo:

I-1) Ukwakhiwa kwezitini eziphikisayo kufanele kwakhiwe ngendlela yokuxova nokucindezela (ngaphandle kokuguqulwa okukhethekile okufana nezitini ezinkulu), futhi ubukhulu obuhlangene bokunweba buzogcinwa njengoba kudingekile, futhi udaka oluphikisayo ekuhlanganyeleni luzogcwaliswa ngokuqinile futhi ngokugcwele.

I-2) Isikhundla sezitini eziphikisayo kanye nobukhulu bezihlanganisi zokunweba zingalungiswa ngokusebenzisa ama-slabs okhuni noma enjoloba. Isakhiwo sezitini esiphelile ngeke singqubuzane noma singqongqozwe kuso.

I-3) Phakathi nenqubo yokwakhiwa kwamatshe, sebenzisa udaka lwe-refractory high-concentration ukuze uthole ukwelashwa okuhlangene ngaphambi kokuba ukuhlanganiswa okunwetshiwe kuqiniswe.

I-4) Izitini eziphikisayo zicutshungulwa ngumsiki wezitini. Indawo ecutshunguliwe akufanele ibhekane nohlangothi lwesithando somlilo kanye nejoyinti lokunweba. Ubude besitini esigaywe akumele bube ngaphansi kwengxenye yobude besitini sokuqala, futhi ububanzi (ubukhulu) besiqondiso sesitini esigaywe abube ngaphansi kobubanzi besitini sokuqala ( Ubukhulu) 2/3 we-degree. .

5) Lapho wakha udonga lwesithando somlilo esiphambanayo, hlola ukuphakama kwezinga nganoma yisiphi isikhathi futhi uphakamise ungqimba ngongqimba. Lapho ushiya noma usebenza kabusha futhi udilizwa, kufanele ishiywe njenge-chamfer enezinyathelo.

(2) Ukulungiswa kodaka lwe-refractory:

I-refractory mortar ye-metallurgical roasted masonry yesithando somlilo kufanele yenziwe nge-refractory mortar efana nempahla yezitini eziphikisayo. I-refractory slurry kufanele ilungiswe ngokuxuba nge-mixer slurry. Zama ukungasebenzisi isitsha sokuxuba esifanayo ukwenza ama-slurries aphikisayo ezinto ezahlukene. Lapho udaka lwe-refractory kufanele lushintshwe, okokusebenza okuxutshwa kanye nesiqukathi kufanele kuhlanjululwe ngamanzi ahlanzekile, bese kushintshwa okokusebenza ukuze kuxutshwe. I-viscosity ye-refractory mortar ingalawulwa ngokuya ngemibandela yokwakhiwa kwendawo, futhi udaka lwe-refractory olusethiwe ekuqaleni ngeke lusetshenziswe.

(3) Ukwakhiwa kwamatshe odongeni lwesithando somlilo:

I-1) Izitini eziphikisayo zodonga lwesithando somlilo kufanele zakhiwe ngezigaba. Ngaphambi kwesigaba ngasinye sodonga lwesithando somlilo, izingqimba ezimbili zengilazi yamanzi ye-graphite powder kufanele zigcotshwe odongeni lwangaphakathi lwegobolondo lesithando somlilo, bese ibhodi lokufaka i-asbestos kufanele linamathiselwe ngokuqinile kungqimba lwe-smear, bese ukwakhiwa kwesithando somlilo. yezitini eziphikisayo ezingasindi kanye nezitini ezinzima eziphikisayo.

I-2) Ingxenye ngayinye yodonga lwesithando somlilo kufanele yakhiwe ngegobolondo lesithando somlilo njenge-sideline ye-masonry, ngenkathi iqinisekisa ukugcwala kwendawo yangaphakathi yesithando somlilo.

3) Lapho izingxenye zamatshe ezinophahla olushisayo, izitini eziphikisayo ezinesisindo esilula kufanele zibekwe endaweni ephakeme ngaphambi kokubeka izitini eziphikisayo ezinesisindo esisindayo ukuze zisebenze.

I-4) Lapho wakha indawo yembobo, indawo yokuvula imbobo kufanele yakhiwe kuqala, futhi udonga lwesithando somlilo oluzungezile luzokwakhiwa phezulu, futhi izitini zokuvala zongqimba ngalunye lwezitini eziphikisayo zamatshe zizosakazwa ngokulinganayo.

(4) Ukwakhiwa kwezitini ze-vault:

I-1) Ngokusho komugqa ophakathi kwesithando somlilo, qala ukwakha izitini ze-arch-foot ukuze ukuphakama kwendawo kufanele kugcinwe emgqeni ofanayo ovundlile.

I-2) Izitini ze-arch-foot ziyizitini ezimise okukhethekile futhi zikhulu ngobukhulu, ngakho-ke indlela yokuxubha ayifaneleki ukwenza amatshe. Ngesikhathi sokwakhiwa, ubuso bezitini eziphikisayo kufanele bugcotshwe ngenani elifanele lodaka oluphikisayo ukwenza izitini eziphikisanayo eziseduze zibe nokuxhumana okuseduze nokuhle.

I-3) Ngemuva kokuthi izitini ze-arch-foot seziqediwe futhi zidlulise ukuhlolwa, qala ukwakha indandatho yokuqala yezitini ze-vault, bese wakha indandatho yesibili ngemva kokwakhiwa kwendandatho yokuqala yezitini zomnyango. Inqubo ye-masonry idinga ukuthi igebe phakathi kwezitini ze-vault kufanele liqine. Ubukhulu bamajoyinti okwandisa abekelwe kufanele bufane ngangokunokwenzeka.

I-4) Izitini zokuvala umnyango wendandatho ngayinye ye-vault kufanele zisakazwe ngokulinganayo ophahleni lwesithando somlilo, futhi ububanzi bezitini zokuvala umnyango akufanele zibe ngaphansi kuka-7/8 wezitini zokuqala, futhi indandatho yokugcina kufanele ibe. ethelwe ngama-castables.

(5) Ukwakhiwa ngokuhlanganyela okunwetshiwe:

Isikhundla kanye nobukhulu bezihlanganisi ezigodliwe zokunwetshwa kwesithando somzimba wesithando somlilo kufanele zisethwe ngokuvumelana nezidingo zokuklama nezokwakha. Amalungu kufanele ahlanzwe ngaphambi kokugcwalisa amalunga okwandisa, futhi izinto eziphikisayo zezinto zokuklama kufanele zigcwaliswe ngokuvumelana nezidingo. Ukugcwaliswa kufanele kube okufanayo futhi kuminyene, futhi ubuso kufanele bube bushelelezi. .