- 04

- Feb

Induction heating welding seam heat treatment method

Induction heating welding seam heat treatment method

Pipeline steel is the main type of steel whose welds require heat treatment to improve mechanical properties. The steels used in different strength steel grades and their requirements for room temperature strength are listed in Table 6-2 . Based on the steel types and mechanical properties listed in Table 6-2 , the main heat treatment methods to improve the overall performance of welds include normalizing treatment, normalizing + tempering treatment, quenching + tempering treatment and other methods. At present, the weld normalizing treatment is mostly used in the production of domestic welded pipes, and other heat treatment methods have not yet been adopted. The most advanced weld heat treatment is the quenching and tempering production line . Normalizing treatment is mostly used in large-scale welded pipe production lines abroad, and quenching and tempering treatment is only used by individual companies in Japan and the European Union. Induction heating quenching and tempering treatment of welds is the direction of future development.

Table 6-2 Standard steel grade and room temperature strength of pipeline steel

| GB/T 9711. 1-1997

වානේ ශ්රේණිය |

API spec 5L— 2004

වානේ ශ්රේණිය |

Mechanical properties at room temperature | යකඩ | |

| %/MPa | ffb /MPa | |||

| එක් | A25 | 172 | 310 | |

| L210 | A | 207 | 331 | කාබන් වානේ |

| L245 | B | 241 | 413 | |

| L290 | X42 | 289 | 413 | |

| L320 | X46 | 317 | 434 | Ordinary low alloy steel |

| L360 | X52 | 358 | 455 | |

| L390 | X56 | 386 | 489 | |

| L415 | X60 | 415 | 517 | Low-alloy high-strength steel |

| L45O | X65 | 448 | 530 | |

| L485 | X70 | 482 | 565 | |

| L555 | X80 | 551 | 620 | Microalloyed high-strength steel |

| – | X100 | 727 | 837 | |

(1) Weld induction heating normalizing treatment includes annealing treatment, sometimes called stress relief annealing. The induction heating normalizing process of the weld is to heat the weld to a temperature above Ae , and then air-cooled to below 400 °C and water-cooled to room temperature after 900~950°C . In this way, the internal stress of the welding is eliminated, the grain of the weld is refined, the microstructure is improved, and the plasticity and impact toughness of the weld are improved. Weld induction heating normalizing treatment is suitable for ordinary low-alloy steel and some low-alloy high-strength steels, equivalent to welded pipes below X60 steel grade. The welding seam induction heating annealing treatment is to heat the welding seam to 700 ~ 750°C dual-phase zone, and then air-cooled to room temperature, the purpose is to eliminate the internal stress of the welding and improve the plasticity. Annealing treatment is mainly used for carbon steel and some ordinary low-alloy steel welded pipes. This process is rarely used in domestic welded pipe production lines.

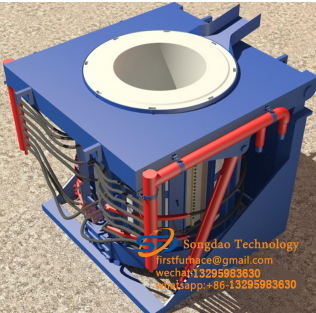

(2) Weld induction heating normalizing + tempering treatment After the normalizing treatment, when the hardness of the weld is still high and the plasticity is still low, high temperature tempering treatment can be used to remedy it. Induction heating and tempering is to heat the weld to a temperature below Ad , usually around 650 ℃ and then air-cooled. After the high temperature tempering treatment, the martensite structure in the raw steel is transformed into tempered sorbite and ferrite, the plasticity of the weld is improved, the hardness is reduced, and the strength changes little.Weld used induction heating furnace quenching and tempering treatment ten this heat treatment method, also known as quenching, quenching and induction heating line weld heat treatment is the most advanced technology. After quenching and tempering, the comprehensive mechanical properties of the welding seam completely reach the level of the pipe body, realizing the uniformity of the welding seam and the pipe body performance. The core of this heat treatment technology is to master the transverse magnetic field heating technology to ensure the uniformity and accuracy of the heating temperature. For low-alloy high-strength steel and micro-synthesized high-strength steel welds, the quenching heating temperature is 900 ~ 950 ℃ , the tempering heating temperature is 600 ~ 650°C, the quenching adopts spray cooling, and the tempering adopts air cooling and water cooling. Combine cooling. When the quenching and tempering temperature is heated by a longitudinal magnetic field, the accuracy of temperature control can reach ± 10°C, which is the necessary temperature control level for high-strength welded pipes to maintain stable performance. Using the transverse field heating welds also require high precision temperature control • currently • China is still in the development stage, from the accuracy of this large difference. However, it is believed that this heating technology will soon be overcome, and the weld seam will be heated and tempered by on-line induction heating.