- 04

- Feb

Ukufudumeza ukufudumeza i-welding i-seam yonyango yokushisa ubushushu

Ukufudumeza ukufudumeza i-welding i-seam yonyango yokushisa ubushushu

Intsimbi yombhobho yolona hlobo luphambili lwentsimbi olune-welds lufuna unyango lobushushu ukuphucula iimpawu zoomatshini. Iintsimbi ezisetyenziswe kumanqanaba ahlukeneyo ensimbi kunye neemfuno zabo zamandla okushisa kwegumbi zidweliswe kwiThebhile 6-2. Ngokusekelwe kwiintlobo zetsimbi kunye neempawu zoomatshini ezidweliswe kwiThebhile 6-2, iindlela eziphambili zonyango lokufudumala ukuphucula ukusebenza ngokubanzi kwee-welds ziquka unyango oluqhelekileyo, ukunyanzeliswa kwesiqhelo + ukunyameka, ukucima + unyango olushushu kunye nezinye iindlela. Okwangoku, unyango lwe-weld normalizing lusetyenziswa kakhulu kwimveliso yemibhobho ye-welded yasekhaya, kwaye ezinye iindlela zokunyanga ubushushu azikamkelwa. Olona nyango luphezulu lwe-weld luyimveliso yokucima kunye neyokuthambisa. Unyango oluqhelekileyo lusetyenziswa kakhulu kwimigca yokuvelisa umbhobho odityanisiweyo omkhulu phesheya, kwaye ukucinywa kunye nonyango olushushu lusetyenziswa kuphela ziinkampani ezizimeleyo eJapan kunye neEuropean Union. Ukucima ukucima ukufudumeza kunye nokunyangwa kwe-welds yindlela yophuhliso lwexesha elizayo.

Itheyibhile 6-2 umgangatho wensimbi oqhelekileyo kunye namandla okushisa kwegumbi lentsimbi yombhobho

| GB/T 9711. 1-1997

Ibakala lesinyithi |

I-API specs 5L— 2004

Ibakala lesinyithi |

Iimpawu zomatshini kwiqondo lokushisa | steel | |

| %/MPa | ffb/MPa | |||

| Nye | A25 | 172 | 310 | |

| L210 | A | 207 | 331 | Insimbi yeCarbon |

| L245 | B | 241 | 413 | |

| L290 | X42 | 289 | 413 | |

| L320 | X46 | 317 | 434 | Intsimbi eqhelekileyo ephantsi |

| L360 | X52 | 358 | 455 | |

| L390 | X56 | 386 | 489 | |

| L415 | X60 | 415 | 517 | Intsimbi ephantsi-i-alloy ephezulu |

| L45O | X65 | 448 | 530 | |

| L485 | X70 | 482 | 565 | |

| L555 | X80 | 551 | 620 | I-Microalloyed high-strength steel |

| – | X100 | 727 | 837 | |

(1) I-Weld induction yokufudumeza unyango oluqhelekileyo lubandakanya unyango lwe-annealing, ngamanye amaxesha lubizwa ngokuba yi-stress annealing. I-induction yokufudumala inkqubo yokulinganisa i-weld kukufudumala i-weld kwiqondo lokushisa ngaphezu kwe-Ae, kwaye emva koko i-air-cooled ukuya ngaphantsi kwe-400 ° C kunye ne-water-cooled kwiqondo lokushisa emva kwe-900 ~ 950 ° C. Ngale ndlela, uxinzelelo lwangaphakathi lwe-welding luyapheliswa, ingqolowa ye-weld ihlanjululwe, i-microstructure iphuculwe, kwaye iplastiki kunye nokuqina kwempembelelo ye-weld kuphuculwe. I-Weld induction heat normalizing treatment ifanelekile kwintsimbi yentsimbi ephantsi kunye nezinye iintsimbi ezisezantsi, ezilingana nemibhobho edityanisiweyo engaphantsi kwe-X60 yentsimbi. I-welding seam induction heat annealing treatment kukufudumeza i-welding seam ukuya kwi-700 ~ 750 ° C kwindawo yesigaba sesibini, kwaye emva koko ipholile emoyeni kwiqondo lokushisa, injongo kukuphelisa uxinzelelo lwangaphakathi lwe-welding kunye nokuphucula iplastiki. Unyango lwe-Anealing lusetyenziswa ikakhulu kwintsimbi yekhabhoni kunye nemibhobho edityanisiweyo yentsimbi ephantsi. Le nkqubo ayifane isetyenziswe kwimigca yokuvelisa imibhobho edityanisiweyo yasekhaya.

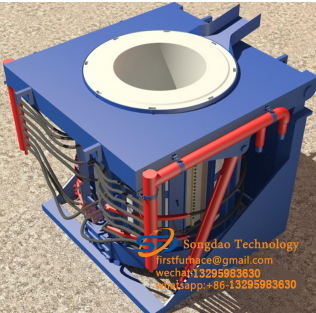

2 Ukufudumeza kwe-Induction kunye nokufudumeza kukufudumeza i-weld kwiqondo lobushushu elingaphantsi kwe-Ad, ngokuqhelekileyo lijikeleze i-650 ℃ kwaye emva koko lipholiswe ngumoya. Emva konyango lobushushu obuphezulu, i-martensite isakhiwo kwintsimbi ekrwada iguqulwa ibe yi-sorbite epholileyo kunye ne-ferrite, i-plasticity ye-weld iphuculwe, ubunzima buyancipha, kwaye amandla atshintsha kancinci. ishumi le ndlela yonyango lobushushu, ekwabizwa ngokuba yi-quenching, ukucima kunye ne-induction yokufudumeza umgca we-weld unyango lobushushu yeyona teknoloji iphambili. Emva kokucima kunye nokufudumala, iimpawu ezibanzi zomatshini we-welding seam zifikelela ngokupheleleyo kwinqanaba lomzimba wombhobho, ukuqonda ukufana kwe-welding seam kunye nokusebenza komzimba wombhobho. Undoqo wobu buchwepheshe bonyango lobushushu kukuqonda itekhnoloji yokufudumeza imagnethi enqamlezayo ukuqinisekisa ukufana kunye nokuchaneka kobushushu bokufudumala. Kwintsimbi ephantsi-intsimbi ephezulu kunye ne-micro-synthesized high-high-forth welds, ubushushu bokucima ubushushu bungama-900 ~ 950 ℃, ubushushu bobushushu bobushushu bungama-600 ~ 650 ° C, ukucima kwamkela ukupholisa isitshizi, kunye nokufudumeza kwamkela umoya. ukupholisa kunye nokupholisa amanzi. Dibanisa ukupholisa. Xa ukucima kunye nokushisa ukushisa kushushu ngummandla wamagnetic we-longitudinal, ukuchaneka kokulawula ubushushu kunokufikelela ku-± 10 ° C, okuyinqanaba elifunekayo lokulawula ubushushu kwimibhobho edibeneyo edibeneyo ukuze kugcinwe ukusebenza okuzinzileyo. Ukusebenzisa i-welds yokufudumeza intsimi enqamlezileyo kufuna ulawulo oluchanekileyo oluphezulu lobushushu • okwangoku • I-China isekwinqanaba lophuhliso, ukusuka ekuchanekeni kwalo mahluko omkhulu. Nangona kunjalo, kukholelwa ukuba le teknoloji yokufudumeza iya koyiswa ngokukhawuleza, kwaye i-weld seam iya kufudumeza kwaye igxininiswe ngokufudumeza kwe-intanethi.