- 05

- Aug

Ukuthuthukiswa Kweziqondiso Zokushisisa Umgodi Wokungeniswa Isithando Somlilo

Ukuthuthukiswa Kweziqondiso Zokushisisa Umgodi Wokungeniswa Isithando Somlilo

Ngokuthuthukiswa kwe ukukhishwa kwamandla okushisa ukuhlinzeka ngobuchwepheshe kanye nenqubekelaphambili yobuchwepheshe bokukhiqiza isithando somlilo sokungeniswa, iziko lokufudumeza lokungeniswa kwemigodi kufanele zithuthukiswe ukuze zibe uhlobo olusha lwesithando somlilo sokushisa esithatha indawo yokushisa yokushisa yokumelana neziko nezinsimbi zensimbi. Ukuthuthukiswa okuqondile kufaka phakathi izici ezilandelayo.

(1) Ukufaka ugesi we-thyristor wefrikhwensi ephakathi nendawo yokunikezwa kwamandla kagesi wezimboni. Ngenxa yokusetshenziswa kwama-transformers kanye nenani elikhulu lama-capacitor okulinganisa, ukusebenza kahle kukagesi we-industrial frequency power supply kuncipha kakhulu. Njengamanje, amandla aphezulu we-thyristor power supply angashintsha ngokuphelele amandla okunikezwa kwamandla okuvama kokwelashwa kokushisa nokushisa kwe-diathermy. Ukunikezwa kwamandla kunokusebenza kahle kukagesi okuphezulu kunokunikezwa kwamandla kagesi, futhi okokusebenza kuthatha indawo encane, ukutshalwa kwezimali okuncane, nokusebenza okuzinzile. Imvamisa yokunikezwa kwamandla okuvama okumaphakathi akulula ukuthi ibe phezulu kakhulu, futhi i-500~1000Hz ifaneleka kakhulu.

(2) Ukwenza ngcono izinto zomzimba wesithando somlilo Igobolondo lesithando somlilo kanye nobakaki womzimba wesithando somlilo kufanele kwenziwe ngezinto ezingezona ezizibuthe njenge-aluminium alloy. Ulwelwesi lwangaphakathi lwe-inductor lungasebenzisa imikhiqizo ye-refractory esungulwe ngaphambili esikhundleni sezinto ze-fiber zokuvikela. Omazibuthe kufanele bahlelwe eduze kwekhoyili yokungeniswa ukuze kuthuthukiswe ukusebenza kahle kukagesi.

(3) Ukuthuthukiswa kohlobo lwesithando somlilo: Shintsha uhlobo lwesithando somgodi sibe isithando somlilo esiwuhlobo lwensimbi ukuze wenze umsebenzi wokukhipha isifuba, khansela isici sokushisa esimelana nesithando somlilo esiwuhlobo lwensimbi, sishintshe sibe ikhoyili yokungeniswa, sebenzisa ukushisisa okungeniswayo, futhi ukhansele.

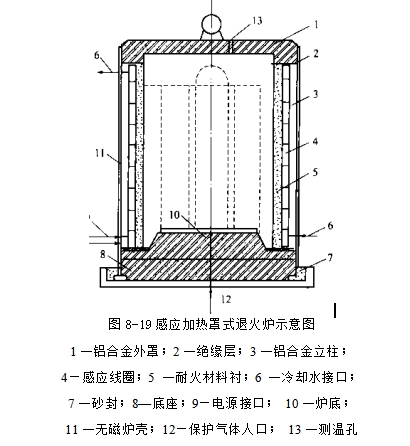

I-liner yensimbi engamelana nokushisa yesithando somlilo sensimbi ifakwe izinto eziphikisayo. Uhlaka olusekelayo lwekhoyili yokungeniswa luthatha isakhiwo esihlanganisiwe sepuleti le-insulating kanye nekholomu yengxubevange ye-aluminium. Isixhumi esibonakalayo sokunikezwa kwamandla kanye nendawo yokupholisa yamanzi nezindawo zokuphuma zifakwe ezingxenyeni ezifanele zegobolondo lesithando somlilo. Inhlanganisela engaguquki noma isikhombimsebenzisi sisetshenziswa ngaphakathi kwegobolondo lesithando somlilo. Ikhebuli yefrikhwensi ephakathi nendawo epholiswe ngamanzi isetshenziswa ngaphandle kwegobolondo lesithando somlilo ukuze kuxhunywe esixhunyweni sokuphakelwa kwamandla, futhi ipayipi lokucindezela lokuphakelwa kwamanzi lixhunywe epayipini lamanzi okupholisa. Ilayini yesithando somlilo eyenziwe ngezinto eziphikisayo isetshenziselwa ukuhlukaniswa phakathi kwekhoyili yokungeniswa nensimbi. Umdwebo wesakhiwo wezinye izingxenye zesithando somlilo uboniswa kuMfanekiso 8-19. Igesi evikelayo ingafakwa esithandweni ukuze kuncishiswe i-oxidation yensimbi efakwe emanzini. Ukushisa kokushisa kwesithando kungcono ku-800 ° C, futhi imbobo yokulinganisa izinga lokushisa inikezwa phakathi kwesembozo sesithando somlilo, futhi i-thermocouple ingasetshenziswa ukukala nokulawula izinga lokushisa lomlilo.

I-liner yensimbi engamelana nokushisa yesithando somlilo sensimbi ifakwe izinto eziphikisayo. Uhlaka olusekelayo lwekhoyili yokungeniswa luthatha isakhiwo esihlanganisiwe sepuleti le-insulating kanye nekholomu yengxubevange ye-aluminium. Isixhumi esibonakalayo sokunikezwa kwamandla kanye nendawo yokupholisa yamanzi nezindawo zokuphuma zifakwe ezingxenyeni ezifanele zegobolondo lesithando somlilo. Inhlanganisela engaguquki noma isikhombimsebenzisi sisetshenziswa ngaphakathi kwegobolondo lesithando somlilo. Ikhebuli yefrikhwensi ephakathi nendawo epholiswe ngamanzi isetshenziswa ngaphandle kwegobolondo lesithando somlilo ukuze kuxhunywe esixhunyweni sokuphakelwa kwamandla, futhi ipayipi lokucindezela lokuphakelwa kwamanzi lixhunywe epayipini lamanzi okupholisa. Ilayini yesithando somlilo eyenziwe ngezinto eziphikisayo isetshenziselwa ukuhlukaniswa phakathi kwekhoyili yokungeniswa nensimbi. Umdwebo wesakhiwo wezinye izingxenye zesithando somlilo uboniswa kuMfanekiso 8-19. Igesi evikelayo ingafakwa esithandweni ukuze kuncishiswe i-oxidation yensimbi efakwe emanzini. Ukushisa kokushisa kwesithando kungcono ku-800 ° C, futhi imbobo yokulinganisa izinga lokushisa inikezwa phakathi kwesembozo sesithando somlilo, futhi i-thermocouple ingasetshenziswa ukukala nokulawula izinga lokushisa lomlilo.