- 14

- Oct

What is the effect of the different original structure of steel on induction hardening?

What is the effect of the different original structure of steel on Induktionshärten?

The speed at which ferrite and cementite transform into austenite depends on the temperature, the composition of the steel, and the original structure.

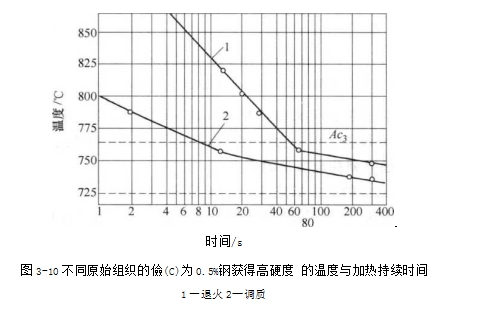

The formation rate of the new austenite phase centers and the growth rate of these centers are determined by the original structure. The more dispersed the original structure, the smaller the distance between the ferrite and cementite particles, so the austenite nucleus is heated. The faster the birth and growth rate. Since the ferrite-cementite mixture forms austenite at the boundary of the division plane of these phases, the finer the original structure, the larger the division plane (reaction effective surface) of the phase. The more dispersed the original tissue is, the shorter the time required for the composition to be uniform when the solid solution is heated. Therefore, the original structure state is very important for induction hardening.

In the normalized or annealed state, the original structure of hypoeutectoid steel is pearlite and free ferrite, and its austenitization speed is slower than that of quenched and tempered sorbite (dispersed ferrite cementite mixture) To be fully quenched, normalized or annealed steel should be quenched and tempered at a higher quenching temperature than quenched and tempered steel.

Another function of obtaining the sorbite structure is to prevent the steel from generating a large residual stress during induction quenching. As everyone knows, the magnitude of residual stress in quenched steel, among other factors, also depends on the quenching temperature. The higher the quenching temperature, the greater the residual stress in the quenched steel. The quenching temperature required for the quenched and tempered structure is the lowest, so the residual stress after quenching is also the smallest, reducing the risk of quenching cracking and spalling. Quenching and tempering treatment can improve the strength of the heart, so it is necessary for important parts that require high mechanical properties.