- 18

- Oct

Cov lus piav qhia ntxaws ntxaws ntawm cov txheej txheem induction hardening ntawm pob pin

Cov ncauj lus kom ntxaws txog high zaus induction hardening txheej txheem ntawm pob tus pin

High-zaus induction hardening yuav tsum: Raws li cov tseev kom muaj ntawm cov qauv sib txawv, koj tuaj yeem xaiv cov khoom siv suab nrov super-hardening thiab cov cuab yeej siv nruab nrab ua kom tawv tawv ntawm lub pob pin)

Feem ntau, txoj haujlwm quenching sib txawv raws li qhov sib txawv ntawm tus pin pob qauv. Piv txwv li, qhov ua tau zoo ntawm kev siv ntau zaus rau kev hnyav rau lub tsheb thauj khoom hnyav hom pob pins feem ntau yog 2-3 hli, thiab txoj haujlwm quenching xav tau lub taub hau pob thiab pob tus pin kom raug tua tag nrho. Rau kev kho saum npoo ntawm pob tus pin ntawm lub tsheb, tsis tas yuav tsum tau quenching, thiab tsuas yog tua ntawm lub taub hau pob tuaj yeem txaus siab rau nws hnav tsis kam thiab lub zog tensile.

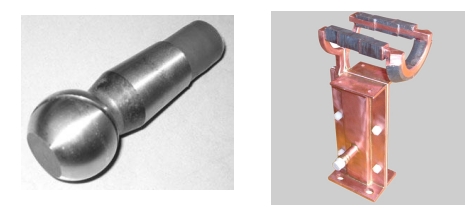

Pob pin ntu Daim duab 1 Pob tus pin siab zaus ua kom lub zog khawb duab 2

Cov txheej txheem tsim khoom ntawm pob tus pin: puag ncig steel blanking-super suab zaus induction cua sov-forging-txiav-siab zaus quenching-sib dhos.

Txhawm rau tiv thaiv qhov tshwm sim ntawm cov khoom sib txawv, cov khoom lag luam tsis raug, sib dhos tsis raug, thiab lwm yam, cov kev ntsuas sib xws raug coj los tiv thaiv kev ua yuam kev, thiab siv lub tshuab tshuaj xyuas tag nrho uas tuaj yeem tshuaj xyuas lub zog, lub viav vias, thiab lwm yam. txheej txheem. nruab nrab.