- 12

- Dec

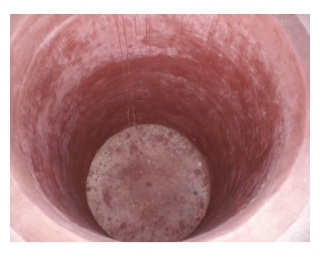

Spoelmortel/spoel wat gegiet kan word vir induksie -oond sonder kern

Spoelmortel/spoel wat gegiet kan word vir induksie -oond sonder kern

Die spoelmortel gebruik gesmelte korund en kalsiumaluminaatsement as die belangrikste grondstowwe, en ‘n redelike saamgestelde weekmaker word gekies om te verseker dat die spoelmortel uitstekende smeerprestasie het. Die besmeerde mortier het voldoende hoë vuurvastheid, druksterkte en hoë temperatuur temperatuur Stabiliteit en goeie isolasie. Spoelpasta is geskik vir induktiewe oonde van alle hoedanighede.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Verpakking: 25 kg/sak, geweefde sak met plastiekvoering.

Let wel: Vogbestande maatreëls moet getref word tydens opberging en droog gehou word. Houdbaarheid: 6 maande.