- 12

- Dec

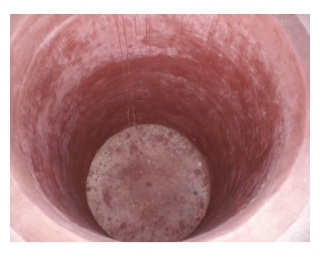

Chokaa cha coil / coil inayoweza kutengwa kwa tanuru ya uingizaji isiyo na msingi

Chokaa cha coil / coil inayoweza kutengwa kwa tanuru ya uingizaji isiyo na msingi

Chokaa cha coil hutumia saruji iliyochanganywa ya corundum na kalsiamu kama malighafi kuu, na plastiki inayofaa inayochaguliwa inachaguliwa kuhakikisha kuwa chokaa cha coil kina utendaji mzuri wa kupaka. Chokaa kilichopakwa kina upungufu mkubwa wa kutosha, nguvu ya kukandamiza na kiwango cha juu cha joto Utulivu na insulation nzuri. Kuweka coil kunafaa kwa tanuu za kuingiza zisizo na msingi za uwezo wote.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Ufungashaji: 25kg / begi, begi iliyofumwa na filamu ya kitambaa cha plastiki.

Kumbuka: Hatua za kuzuia unyevu zinapaswa kuchukuliwa wakati wa kuhifadhi na kuweka kavu. Maisha ya rafu: miezi 6.