- 12

- Dec

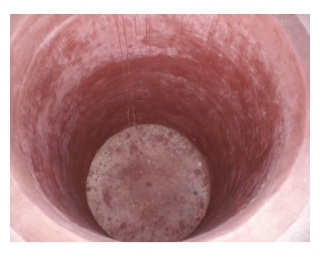

Spolemørtel/spole, der kan støbes til kerneløs induktionsovn

Spolemørtel/spole, der kan støbes til kerneløs induktionsovn

Spolemørtlen anvender smeltet korund og calciumaluminatcement som de vigtigste råvarer, og en rimelig sammensat blødgører vælges for at sikre, at spolemørtel har fremragende udtværingsevne. Den udtværede mørtel har tilstrækkelig høj ildfasthed, trykstyrke og høj temperatur volumen Stabilitet og god isolering. Spolepasta er velegnet til kerneløse induktionsovne med alle kapaciteter.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Pakning: 25 kg/pose, vævet pose med plastforingsfilm.

Bemærk: Der skal træffes fugtsikre foranstaltninger under opbevaring og opbevares tørt. Holdbarhed: 6 måneder.