- 12

- Dec

Coil mortar / coil castable untuk relau induksi tanpa karat

Coil mortar / coil castable untuk relau induksi tanpa karat

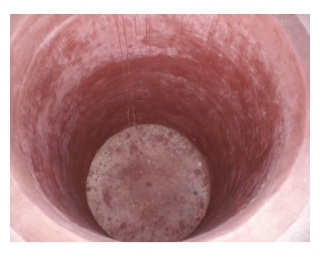

Mortir gegelung menggunakan semen corundum dan kalsium aluminat sebagai bahan mentah utama, dan pemplastik komposit yang wajar dipilih untuk memastikan bahawa mortar gegelung mempunyai prestasi smear yang sangat baik. Mortar yang dioleskan mempunyai daya tahan yang cukup tinggi, kekuatan mampatan dan isipadu suhu tinggi dan penebat yang baik. Coil paste sesuai untuk tungku induksi tanpa karat dari semua kapasiti.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Pembungkusan: 25kg / beg, beg anyaman dengan lapisan plastik.

Catatan: Langkah-langkah tahan kelembapan harus diambil semasa penyimpanan dan dijaga kering. Jangka hayat: 6 bulan.