- 12

- Dec

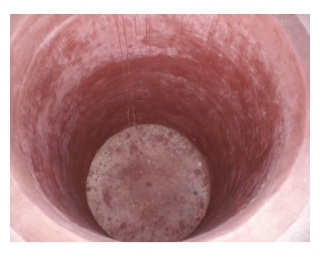

Coar mortir / coil castable for coreless induction furnace

Coar mortir / coil castable for coreless induction furnace

Mortir koil nggunakake semen corundum lan kalsium aluminasi minangka bahan baku utama, lan plastisis komposit sing dipilih kanggo mesthekake yen mortir coil nduweni kinerja smearing sing apik banget. Lempung sing diolesi nduweni refraksi sing cukup dhuwur, kekuatan kompresi lan Stabilitas volume suhu dhuwur lan insulasi sing apik. Pasta coil cocok kanggo tungku induksi tanpa korporasi kabeh kapasitas.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Pengepakan: 25kg / tas, tas anyaman nganggo film lapisan plastik.

Cathetan: Tindakan tahan lembab kudu ditindakake sajrone disimpen lan tetep garing. Umur rak: 6 wulan.