- 12

- Dec

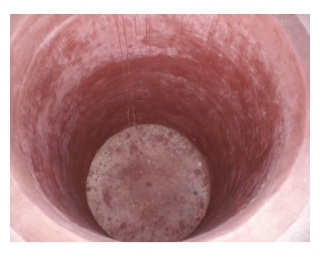

Coil dhaka / coil inokandirwa ye coreless induction choto

Coil dhaka / coil inokandirwa ye coreless induction choto

Iyo coil dhaka inoshandisa fused corundum uye calcium aluminate samende seyakanyanya mbishi zvigadzirwa, uye inonzwisisika yemubatanidzwa plasticizer inosarudzwa kuona kuti coil dhaka ine yakanakisa yekuzora mashandiro. Iyo yakazorwa dhaka ine yakakwana zvakakwana refractoriness, inomanikidza simba uye yakakwira-tembiricha vhoriyamu Kugadzikana uye kwakanaka kuputira. Coil paste inokodzera isina-isina induction maficha eese masimba.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Kurongedza: 25kg / bhegi, rakarukwa bhegi nepurasitiki lining firimu.

Ongorora: Hunyoro-humbowo matanho anofanirwa kutorwa panguva yekuchengetedza uye akachengetwa akaoma. Pasherufu hupenyu: 6 months.