- 12

- Dec

Yadro bo’lmagan indüksiyon o’choq uchun rulonli ohak/rulon

Yadro bo’lmagan indüksiyon o’choq uchun rulonli ohak/rulon

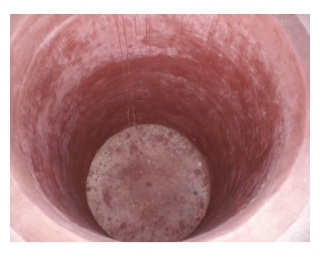

Bobinli ohak asosiy xom ashyo sifatida erigan korund va kaltsiy alyuminat tsementidan foydalanadi va g’altak ohakining eng yaxshi bo’yash ko’rsatkichlariga ega bo’lishini ta’minlash uchun oqilona kompozit plastifikator tanlanadi. Bo’yalgan ohak etarlicha yuqori refrakterlik, bosim kuchi va yuqori haroratli stabillik va yaxshi izolyatsiyaga ega. Bobin pastasi barcha quvvatlardagi yadrosiz indüksiyon pechlari uchun javob beradi.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Qadoqlash: 25 kg/sumka, plastik qoplamali plyonkali to’quv sumka.

E’tibor bering: saqlash vaqtida namlikka qarshi choralar ko’rish va quruq holda saqlash kerak. Yaroqlilik muddati: 6 oy.