- 12

- Dec

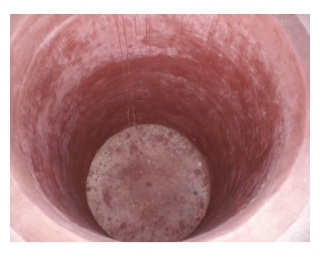

Coil mortar / coil castable para sa coreless induction furnace

Coil mortar / coil castable para sa coreless induction furnace

Ang coil mortar ay gumagamit ng fused corundum at calcium aluminate na semento bilang pangunahing hilaw na materyales, at isang makatuwirang pinaghalong plasticizer ang napili upang matiyak na ang coil mortar ay may mahusay na pagganap ng smearing. Ang smeared mortar ay may sapat na mataas na repraktibo, compressive lakas at mataas na temperatura na lakas Katatagan at mahusay na pagkakabukod. Ang coil paste ay angkop para sa mga coreless induction furnaces ng lahat ng mga capacities.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Pag-iimpake: 25kg / bag, pinagtagpi na bag na may plastic lining film.

Tandaan: Ang mga pamamaraang patunay sa kahalumigmigan ay dapat gawin habang tinitipid at pinapanatiling matuyo. Buhay ng istante: 6 na buwan.