- 12

- Dec

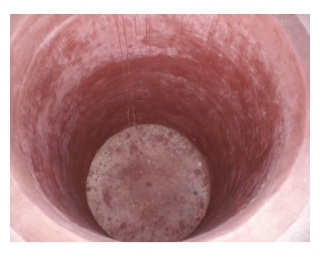

I-coil mortar / coil castable kwiziko lesiseko sokungeniswa

I-coil mortar / coil castable kwiziko lesiseko sokungeniswa

Umdaka wekhoyili usebenzisa i-corundum edityanisiweyo kunye ne-calcium aluminate cement njengezona zinto ziphambili ziphambili, kwaye kukhethwe iplastizerizer efanelekileyo yokuqinisekisa ukuba udaka lwekhoyili lunentsebenzo entle yokugcoba. Udaka olugciniweyo lunobumbeko oluphezulu ngokwaneleyo, amandla okucinezelwa kunye nobushushu obuphezulu bokuqina kunye nokugquma kakuhle. Ukuncamathisela kwekhoyili kulungele iifanishi zokungeniswa ezingenasiseko samandla onke.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Ukupakisha: 25kg / ibhegi, ibhegi ephothiweyo nefilimu yeplastiki.

Qaphela: Amanyathelo okuqinisekisa ukufuma kufuneka athathwe ngexesha lokugcinwa kwaye agcinwe omile. Ubomi beshelf: iinyanga ezi-6.