- 12

- Dec

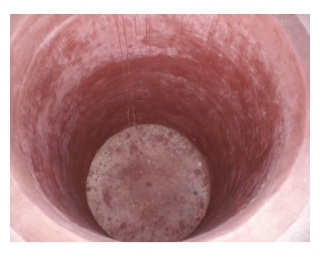

Mortir coil / coil castable pikeun tungku induksi coreless

Mortir coil / coil castable pikeun tungku induksi coreless

Mortir coil nganggo fund corundum sareng kalsium aluminate semén salaku bahan baku utami, sareng plasticizer komposit anu wajar dipilih pikeun mastikeun yén mortir coil ngagaduhan kinerja smearing anu hadé. Mortir anu dioleskeun gaduh répractoriness anu cekap tinggi, kakuatan komprési sareng stabilitas volume suhu luhur sareng insulasi anu saé. Témpél coil cocog pikeun tungku induksi coreless sadaya kamampuan.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Pakét: 25kg / kantong, anyaman kantong sareng pilem pelapis plastik.

Catetan: Ukuran beueus-buktosna kedah dilaksanakeun nalika disimpen sareng dijaga garing. Umur rak: 6 bulan.