- 12

- Dec

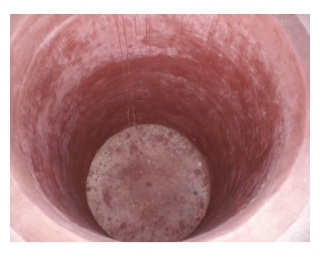

Bobin mòtye / bobin castable pou fou endiksyon coreless

Bobin mòtye / bobin castable pou fou endiksyon coreless

Mòtye a bobin itilize korundum kole ak siman aluminat kalsyòm kòm materyèl prensipal yo anvan tout koreksyon, ak yon plastifyan konpoze rezonab chwazi asire ke mòtye a bobin gen ekselan pèfòmans smearing. Mòtye a andwi gen ase segondè refractoriness, fòs konpresiv ak segondè-tanperati volim Estabilite ak bon izolasyon. Bobin keratin se apwopriye pou fou endiksyon coreless nan tout kapasite.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Anbalaj: 25kg / sak, sak trikote ak fim pawa plastik.

Remak: Mezi imidite-prèv yo ta dwe pran pandan depo epi kenbe sèk. Lavi etajè: 6 mwa.