- 12

- Dec

Coil seretse / li-coil tse ka lahleheloang bakeng sa sebopi sa ho kenya se se nang motheo

Coil seretse / li-coil tse ka lahleheloang bakeng sa sebopi sa ho kenya se se nang motheo

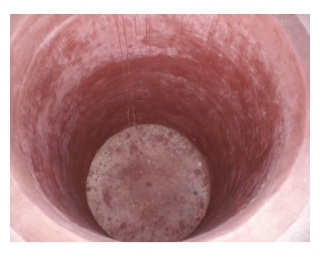

Seretse sa coil se sebelisa samente e kopantsoeng ea corundum le calcium aluminate e le lisebelisoa tse ka sehloohong tse tala, ‘me ho khethoa polasetiki e nang le kahlolo e utloahalang ho netefatsa hore seretse sa coil se na le ts’ebetso e ntle ea ho tlotsa. Seretse se tlotsitsoeng se na le ts’ebeliso e phahameng e lekaneng, matla a kopanyang le botsitso bo phahameng ba mocheso le ho kenya lintho hantle. Pente ea Coil e loketse sebopi sa ho kenella se se nang mantlha sa matla ohle.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Ho paka: 25kg / mokotla, mokotla o lohiloeng o nang le filimi ea lera la polasetiki.

Tlhokomeliso: Mehato e netefatsang mongobo e lokela ho nkuoa nakong ea polokelo ebe e lula e omme. Raka, athe bophelo: likhoeli tse 6.