- 12

- Dec

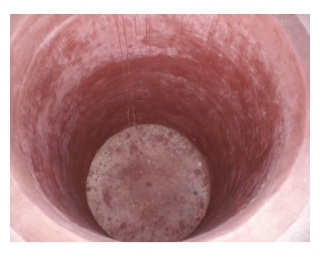

Coil turmi/coil castable for coreless induction makera

Coil turmi/coil castable for coreless induction makera

Turmi mai murɗawa yana amfani da corundum mai haɗewa da allium aluminate ciminti a matsayin manyan albarkatun ƙasa, kuma an zaɓi madaidaicin plasticizer don tabbatar da cewa turmin murɗa yana da kyakkyawan aikin shafawa. Turmi mai smeared yana da isasshen ƙima mai ƙarfi, ƙarfin matsawa da ƙarar zafin jiki Mai ƙarfi da kwanciyar hankali. Coil manna ya dace da murhun shigarwa mara ƙarfi na kowane iyawa.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Shiryawa: 25kg/jakar, jakar da aka saka tare da fim ɗin rufi.

Lura: Yakamata a ɗauki matakan tabbatar da danshi yayin ajiya kuma a bushe. Rayuwar shiryayye: watanni 6.