- 12

- Dec

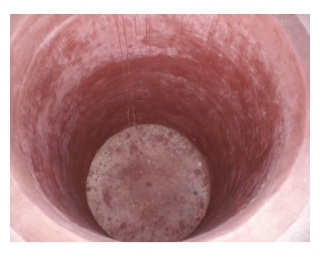

Icoil mortar / coil castable for coreless induction furnace

Icoil mortar / coil castable for coreless induction furnace

Udaka lwekhoyili lusebenzisa i-corundum ne-calcium aluminate cement ehlanganisiwe njengezinto zokusetshenziswa eziyinhloko, futhi kukhethwa i-plasticizer esezingeni elifanele ukuqinisekisa ukuthi udaka lwekhoyili lusebenza kahle ngokugcoba. Udaka olugcotshisiwe lunokuphindwa ngokwanele okuphezulu, amandla acindezelayo kanye nevolumu ephezulu yokushisa Ukuqina nokufakwa kahle. Ukunamathisela kwe-Coil kufanelekele iziko lokungeniswa elingenasisekelo lawo wonke amandla.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Ukupakisha: 25kg / isikhwama, isikhwama eselukiwe nefilimu lepulasitiki.

Qaphela: Izinyathelo zokuqinisekisa umswakama kufanele zithathwe ngesikhathi zigcinwa futhi zigcinwe zomile. Impilo eshalofini: izinyanga ezingu-6.