- 12

- Dec

Coil mortar/coil castable rau qhov tsis muaj cua sov rauv

Coil mortar/coil castable rau qhov tsis muaj cua sov rauv

Cov phom cug siv fused corundum thiab calcium aluminate MAAs ua cov khoom siv tseem ceeb, thiab tsim nyog cov yas yas sib xyaw tau xaiv los xyuas kom meej tias cov tshuaj txhuam hniav tau ua haujlwm zoo smearing. Cov tshuaj khib nyiab tau ua kom zoo txaus ua kom zoo dua qub, ua kom lub zog ruaj khov thiab ntim qhov kub thiab txias ruaj khov thiab rwb thaiv tsev zoo. Coil muab tshuaj txhuam yog qhov tsim nyog rau qhov tsis muaj qhov cub tawg ntawm txhua lub peev xwm.

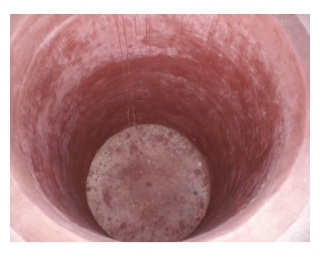

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Ntim: 25kg/hnab, hnab ntim nrog zaj duab xis yas yas.

Nco tseg: Cov ntsuas ntsuas pov thawj yuav tsum tau ua thaum khaws cia thiab khaws cia kom qhuav. Txee lub neej: 6 lub hlis.