- 12

- Dec

Eriri igwe ngwa ngwa/eriri igwe nwere ike ịwụnye ọkụ na -enweghị isi

Eriri igwe ngwa ngwa/eriri igwe nwere ike ịwụnye ọkụ na -enweghị isi

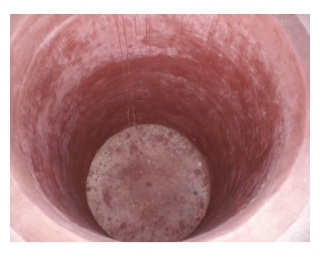

Ngwa agha ahụ na -eji corundum fused na calcium aluminate ciment dị ka akụrụngwa bụ isi, yana plasticizer mejupụtara nwere ezi uche iji hụ na ngwa agha ahụ nwere arụmọrụ kacha mma. Ngwa agha a na-ete ete nwere ntụpọ dị elu zuru oke, ike mkpakọ na olu oke okpomọkụ kwụsie ike na mkpuchi dị mma. Mpempe akwụkwọ eriri igwe dabara adaba maka ọkụ ọkụ na -enweghị isi nke ike niile.

The coil castable uses sintered corundum, calcium aluminate cement, alumina hollow spheres, etc. as the main raw materials. The appropriate particle size gradation is selected to ensure that the coil castable has excellent flow properties, and the castable after construction has high strength and extremely high Refractoriness, high temperature volume stability and thermal insulation performance. Coil castables are especially suitable for large and medium-sized coreless induction furnaces.

The use of coil mortar/coil casting material can avoid the mechanical damage to the coil of the coreless induction furnace in the process of furnace building and rapid dismantling; when the molten metal leaks, the molten metal and the induction coil are isolated to protect the induction coil. Burned down to avoid accidents such as explosions.

Mbukota: 25kg/akpa, akpa akpa nwere ihe nkiri plastik.

Rịba ama: Ekwesịrị ịme ihe na-egbochi mmiri n’oge nchekwa ma debe ya nkụ. Ndụ shelf: ọnwa 6.