- 31

- Oct

セメントロータリーキルンの耐火物ライニングの摩耗の影響要因

セメントロータリーキルンの耐火物ライニングの摩耗の影響要因

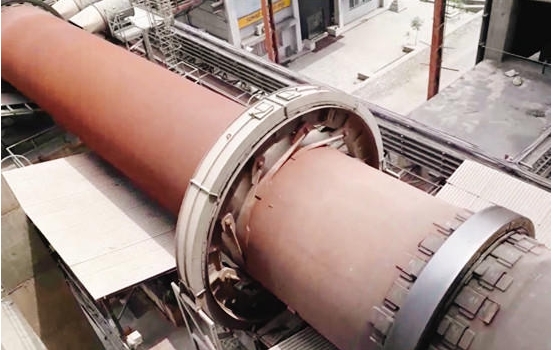

As the main equipment for calcination of cement clinker in cement plants, the rotary kiln can also be used in the lime industry. It has the characteristics of large output, uniform product calcination, and stable production. Commonly used refractory materials mainly include high alumina bricks, phosphate bonded high alumina bricks, anti-stripping high alumina bricks, mullite alkali-resistant composite bricks, silica-molded bricks, magnesia refractory bricks, steel fiber reinforced refractory castables, and low cement castables , Anti-skinning castable, etc.

Rotary kiln equipment can be divided into front kiln mouth, lower transition zone, firing zone, upper transition zone, decomposition zone and rear kiln mouth. According to the operating environment and temperature of each part, in the production operation of the rotary kiln, The refractory lining of its lining will be affected by the turning movement of the cylinder and the material, the influence of the combustion flue gas of the coal injection pipe and the high temperature charge, and the erosion of harmful gases, etc., and also include the kiln masonry design, refractory quality, masonry Building quality, oven requirements, etc., will shorten the service life of the lining refractories.

In order to ensure the long-term and continuous safe operation of the rotary kiln, the refractory lining of the rotary kiln should be as stable and as long as possible, but there are many factors that affect the service life of the rotary kiln. The refractory lining of the kiln is mainly subjected to three aspects: mechanical stress, thermal stress and chemical erosion. The role of.

1. The influence of mechanical stress on the refractory material of the rotary kiln lining:

In the normal production process of the rotary kiln, the relative movement of the cylinder, materials, dust-laden furnace gas, etc. and the inner lining itself causes the refractory to be subjected to gravity load and abrasion. When the mechanical stress load exceeds the strength limit that the refractory can withstand At this time, it will cause rapid damage to the refractory material.

The main mechanical stress generating factors are as follows:

(1) The cylinder is deformed. The total weight of the refractory materials, materials and the barrel body in the kiln exceeds the strength of the barrel body or the local burning temperature is too high. Damaged and peeled brick lining occurred.

(2)軸オフセット。 タイヤベルト、サポートローラー、ローラーサポート、およびロータリーキルンの軸上の各破損した中心点は直線上にある必要があります。 自重の影響で中心軸がずれます。 一定期間の操作後、タイヤとローラーはさまざまな程度の摩耗とシフトを経験します。 各支持点の耐荷重能力が不均一になり、軸が強くなります。 オフセットの量、ライニング耐火材料は、押し出しによって損傷したり、脱落したりします。

(3)建設品質。 不合理な設計や組積造の問題により、耐火物が操作中に緩んでずれや歪みが生じ、ロータリーキルンの連続運転中にシリンダーと裏打ちされた耐火物の相対運動が発生し、耐火物は相互に影響を受ける。 この効果により、押し出し転位が発生し、さらには剥離や脱落が発生します。

2. The influence of thermal stress on the refractory materials of the rotary kiln:

Thermal stress means that during the heating process of the kiln, the refractory materials are extruded due to different degrees of thermal expansion, and because they cannot expand freely, when the force exceeds the strength of the refractory material itself, the refractory material in the kiln will be damaged , Peeling and other phenomena. In addition, with the operation of the kiln, periodic fluctuations in the surface temperature of the lining refractory material will affect it; and when the kiln starts and stops, the temperature change of alternating cold and heat will also affect the lining of the kiln. The influence of temperature changes on the kiln lining inside the kiln is also one of the reasons for the damage of the kiln lining.

3. The influence of chemical attack on the refractory materials of the rotary kiln:

ロータリーキルンでの耐火物の化学的攻撃は、主に原材料と燃料自体の煆焼から生じます。 原料中の不純物には、SiO2、Fe2O3、Na2O、K2Oなど、燃料S、P、Clなどの化合物中の不純物が含まれます。 これらの不純物は高温環境に浸されます。 耐火材料の内部では、耐火ライニングマトリックスと化学反応が起こり、耐火材料に一連の損傷を引き起こします。 高温での液相材料と耐火物の表面との間の化学反応、ならびにアルカリ塩などの有害物質の浸透および侵食により、耐火物の表面反応層は、結合物に遭遇したときに剥離および亀裂を引き起こす。熱的および機械的ストレスの影響。