- 31

- Oct

Izinto ezinomthelela wokuguga nokudabuka kolwelwesi oluphikisayo lwehhavini likasimende elijikelezayo

Izinto ezinomthelela wokuguga nokudabuka kolwelwesi oluphikisayo lwehhavini likasimende elijikelezayo

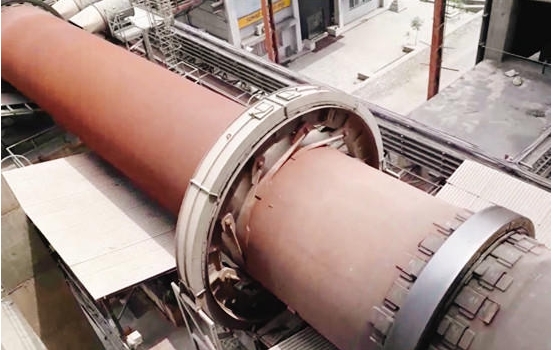

Njengethuluzi eliyinhloko lokubala i-clinker kasimende ezitshalweni zikasimende, i-rotary kiln ingasetshenziswa futhi embonini ye-lime. Inezici zokuphuma okukhulu, ukubala okufanayo komkhiqizo, nokukhiqiza okuzinzile. Izinto ezisetshenziswa kakhulu eziphikisayo ikakhulukazi zifaka izitini eziphakeme ze-alumina, izitini eziboshwe nge-phosphate eziphakeme ze-alumina, izitini eziphakeme ze-alumina ezinqamula ukuhlubula, izitini eziyinhlanganisela ye-alkali engazweli, izitini ezibunjwe nge-silica, izitini eziphikisayo ze-magnesia, izintambo zensimbi eziqiniswe nge-fiber eqinile, nezinsimbi ezincishisiwe zikasimende, I-anti-skinning castable, njll.

Imishini ye-rotary kiln ingahlukaniswa ibe nomlomo ongaphambili, indawo yokuguqula ephansi, indawo yokudubula, indawo yoguquko ephezulu, indawo yokubola kanye nomlomo wesibaya wangemuva. Ngokwendawo yokusebenza kanye nezinga lokushisa kwengxenye ngayinye, ekusebenzeni kokukhiqizwa kwe-rotary kiln, I-refractory lining ye-lining yayo izothinteka ekuphenduleni ukunyakaza kwe-cylinder kanye nezinto ezibonakalayo, ithonya legesi evuthayo ye-flue yamalahle. ipayipi lomjovo kanye neshajethi ephezulu yokushisa, nokuguguleka kwamagesi ayingozi, njll., futhi kufaka phakathi idizayini yeziko lomlilo, ikhwalithi ephikisayo, ikhwalithi yesakhiwo samatshe, izidingo zikahhavini, njll., kuzofinyeza impilo yesevisi yezifanisi zothango.

Ukuze kuqinisekiswe ukusebenza okuphephile okuhlala isikhathi eside nokuqhubekayo kwe-rotary kiln, i-refractory lining ye-rotary kiln kufanele ibe yizinzile futhi ibe yinde ngangokunokwenzeka, kodwa kunezici eziningi ezithinta impilo yesevisi ye-rotary kiln. Ulwelwesi oluphikisayo lweziko lubhekene kakhulu nezici ezintathu: ukucindezeleka komshini, ukucindezeleka okushisayo kanye nokuguguleka kwamakhemikhali. Indima ye.

1. Umthelela wokucindezelwa komshini kuzinto eziphikisayo zolayini lwe-rotary kiln:

Enqubweni evamile yokukhiqiza ye-rotary kiln, ukunyakaza okuhlobene kwesilinda, izinto zokwakha, igesi yomlilo egcwele uthuli, njll. kanye nolwelwesi lwangaphakathi ngokwalo kubangela ukuthi i-refractory ibe ngaphansi komthwalo wamandla adonsela phansi kanye nokuhuzuka. Lapho umthwalo wokucindezeleka wemishini udlula umkhawulo wamandla i-refractory engamelana nayo Ngalesi sikhathi, izodala umonakalo osheshayo wezinto eziphikisayo.

Izici eziyinhloko ezidala ukucindezeleka kwemishini zimi kanje:

(1) Isilinda sikhubazekile. Isisindo esiphelele sezinto eziphikisayo, izinto zokwakha kanye nomzimba womgqomo kuhhavini sidlula amandla omzimba womgqomo noma izinga lokushisa elivuthayo lendawo liphezulu kakhulu. Kwenzeke ulayini lwezitini olonakele futhi oluxebuliwe.

(2) I-axis offset. Ibhande lamasondo, i-roller esekelayo, i-roller support kanye nephoyinti lesikhungo ngalinye eliphukile ku-axis ye-rotary kiln kufanele ibe emgqeni oqondile. Ngaphansi kwethonya lamandla adonsela phansi ayo, i-axis emaphakathi izoshintsha. Ngemva kwesikhathi sokusebenza, amathayi nama-roller azothola amazinga ahlukene okuguga nokuguquka. Umthamo wokuthwala umthwalo wephoyinti ngalinye lokusekela uba ngokungalingani, okuqinisa i-axis. Inani le-offset, i-lining refractory material izolimala noma ziwe ngenxa yokukhishwa.

(3) Ikhwalithi yokwakha. Ngenxa yokuklama okungenangqondo noma izinkinga zamatshe, izinto eziphikisayo ziyakhululwa ngesikhathi sokusebenza, okubangela ukungahambi kahle nokuhlanekezela, futhi ngesikhathi sokusebenza okuqhubekayo kwe-rotary kiln, ukunyakaza okuhlobene kwe-cylinder kanye nezinto eziphikisayo ezilayishiwe zenzeka, futhi izinto eziphikisayo ziyavumelana. abathintekayo. Umthelela udala ukuphuma kwe-extrusion, ngisho nokuphuma noma ukuwa.

2. Umthelela wengcindezi yokushisa ezintweni eziphikisayo ze-rotary kiln:

Ukucindezeleka okushisayo kusho ukuthi ngesikhathi sokushisa kwehhavini, izinto eziphikisayo zikhishwa ngenxa yamazinga ahlukene okwanda okushisayo, futhi ngenxa yokuthi azikwazi ukwandisa ngokukhululekile, lapho amandla edlula amandla ezinto eziphikisayo ngokwazo, izinto eziphikisayo kuhhavini. izolimala , Ukucwecwa kanye nezinye izenzakalo. Ngaphezu kwalokho, ngokusebenza kweziko, ukuguquguquka ngezikhathi ezithile kwezinga lokushisa elingaphezulu kwento ephikisayo yolwelwesi kuzoyithinta; futhi lapho isibaya siqala futhi sima, ukushintsha kwezinga lokushisa okushintshashintshayo kwamakhaza nokushisa nakho kuzothinta ulwelwesi lweziko. Umthelela wokushintsha kwezinga lokushisa odongeni lwesithando somlilo ngaphakathi kohhavini ungenye yezizathu zokulimala kolwelwesi lwesithando somlilo.

3. Umthelela wokuhlaselwa kwamakhemikhali ezintweni eziphikisayo ze-rotary kiln:

Ukuhlaselwa kwamakhemikhali kwezinto eziphikisayo kuhhavini elijikelezayo ikakhulukazi kuvela ekubalweni kwezinto ezingavuthiwe kanye nophethiloli ngokwawo. Ukungcola ezintweni zokusetshenziswa kuhlanganisa i-SiO2, Fe2O3, Na2O, K2O, njll., kanye nokungcola kuphethiloli S, P, Cl nezinye izinhlanganisela. Lokhu kungcola kucwiliswa ezindaweni ezishisa kakhulu. Ngaphakathi kwezinto eziphikisayo, ukusabela kwamakhemikhali kwenzeka nge-matrix ye-refractory lining, okubangela uchungechunge lokulimala kwento ephikisayo. Ukusabela kwamakhemikhali phakathi kwezinto zesigaba se-liquid kanye nengaphezulu le-refractory ekushiseni okuphezulu, kanye nokungena nokuguguleka kwezinto eziyingozi njengosawoti we-alkali, kubangela ungqimba olungaphezulu lokusabela lwe-refractory ukuba luxebuke futhi luqhekeke lapho luhlangana nokuhlanganisiwe. umphumela wokucindezeleka okushisayo kanye nemishini.