- 31

- Oct

Kupesvedzera zvinhu zvekupfeka uye kubvaruka kwerefractory lining ye simenti rotary kiln

Kupesvedzera zvinhu zvekupfeka uye kubvaruka kwerefractory lining ye simenti rotary kiln

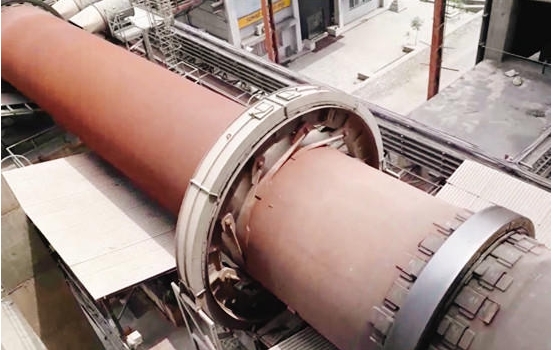

Semudziyo mukuru wekuverengera simende clinker muzvirimwa zvesimende, kiln inotenderera inogona kushandiswawo muindasitiri yeraimu. Iyo ine hunhu hwekubuda kukuru, yunifomu yechigadzirwa calcination, uye yakagadzikana kugadzirwa. Zvishandiso zvinoramba zvichishandiswa zvinonyanya zvinosanganisira zvidhinha zvakakwirira zvealuminium, phosphate yakasungirirwa zvidhinha zvakakwirira zvealuminium, anti-kubvisa zvidhinha zvakakwirira zvealumina, mullite alkali-resistant composite zvidhinha, zvidhinha zvakaumbwa nesilika, magnesia refractory zvidhinha, simbi fiber yakasimbiswa refractory castables, uye yakaderera simende castables. Anti-skinning castable, nezvimwe.

Rotary kiln yemidziyo inogona kukamurwa kuita pamberi pehuni muromo, yakaderera yekuchinja nzvimbo, yekupfura nzvimbo, yekumusoro shanduko nzvimbo, decomposition zone uye kumashure honi muromo. Zvinoenderana nemamiriro ekushanda uye tembiricha yechikamu chega chega, mukugadzirwa kwehuni inotenderera, Iyo refractory lining ye lining yayo ichakanganiswa nekuchinja kwe cylinder uye zvinhu, pesvedzero yekupisa gasi remarasha. jekiseni pombi uye tembiricha yekuchaja, uye kukukurwa kwemagasi anokuvadza, nezvimwewo, uye zvakare inosanganisira dhizaini yekugadzira masonry, refractory mhando, masonry Kuvaka mhando, zvinodiwa muovheni, nezvimwewo, zvinopfupisa hupenyu hwesevhisi yezvigadziriso zvembatya.

Kuti uve nechokwadi chekushanda kwakachengeteka kwenguva refu uye kuenderera mberi kwehuni inotenderera, iyo refractory lining yehuni inotenderera inofanira kunge yakagadzikana uye yakareba sezvinobvira, asi pane zvinhu zvakawanda zvinokanganisa hupenyu hwebasa rehuni inotenderera. Iyo refractory lining yehuni inonyanya kuiswa kune matatu maficha: mechanical stress, thermal stress and chemical erosion. Basa re.

+

Muchigadziro chekugadzirwa kwehuni inotenderera, kufamba kwehumburumbira, zvinhu, guruva-rakaremerwa muchoto gasi, nezvimwewo uye mukati memukati pachayo kunoita kuti refractory iite pasi pesimba regiravhiti uye abrasion. Kana iyo mechanical stress load inodarika simba rekugadzirisa iyo refractory inogona kumira Panguva ino, inokonzera kukurumidza kukanganisa kwezvinhu zvinoramba.

Iwo main mechanical stress generating factors ndeaya anotevera:

(1) Silinda yakaremara. Huremu hwese hwezvinhu zvinoramba, zvinhu uye mbiya muviri muchoto inodarika simba remuviri wembiya kana tembiricha yekupisa yenzvimbo yakakwira zvakanyanya. Zvidhinha zvakakuvadzwa uye zvakasvunurwa.

(2) Axis offset. Bhandi revhiri, rinotsigira roller, roller rutsigiro uye imwe neimwe yakaputsika nzvimbo yepakati pane axis yehuni inotenderera inofanira kunge iri mumutsara wakatwasuka. Pasi pesimba regiravhiti rayo pachayo, iyo yepakati axis ichachinja. Mushure menguva yekushanda, matai nema rollers achaona madhigirii akasiyana ekupfeka uye kuchinja. Iyo inotakura-inotakura simba yeimwe neimwe yekutsigira poindi inova isina kuenzana, iyo inowedzera axis. Huwandu hwekubvisa, iyo lining refractory zvinhu ichakuvadzwa kana kutodonha nekuda kweextrusion.

(3) Kuvaka unhu. Nekuda kwekusanzwisisika dhizaini kana masonry matambudziko, zvinhu zvinoramba zvinosunungurwa panguva yekushanda, zvichikonzera kusarongeka uye kukanganisa, uye panguva yekuenderera kwekushanda kwemoto unotenderera, kufamba kwakabatana kwecylinder uye mitsara refractory zvinhu zvinoitika, uye zvinhu zvinoramba zvichiwirirana. vakanganiswa. Mhedzisiro yacho inokonzera extrusion dislocation, uye kunyange spalling kana kudonha.

2. Kupesvedzera kwekushushikana kwekushisa pane zvinoramba zvemidziyo yemoto inotenderera:

Thermal stress inoreva kuti panguva yekupisa kwechoto, zvinhu zvinoramba zvichiwedzerwa nekuda kwemadhigirii akasiyana ekuwedzera kwekupisa, uye nekuti haakwanise kuwedzera zvakasununguka, kana simba richipfuura simba reiyo refractory zvinhu pachayo, iyo refractory zvinhu muchoto. ichakuvadzwa , Peeling uye zvimwe zviitiko. Uye zvakare, nekushanda kwechoto, kushanduka kwenguva nenguva mukupisa kwepamusoro kweiyo lining refractory zvinhu kuchaikanganisa; uye kana honi yatanga nekumira, kushanduka kwetembiricha yekutsinhanisa kutonhora nekupisa kuchakanganisawo mbiru yevira. Kupesvedzera kwekushanduka kwetembiricha pachoto chebira mukati mechoto zvakare chimwe chezvikonzero zvekukuvadzwa kwembambo yemoto.

3. Mhedziso yekurwisa kwemakemikari pazvinhu zvinoramba zvemoto inotenderera:

Kurwiswa kwemakemikari kwezvinhu zvinoramba mumoto unotenderera zvakanyanya kunobva mukuverengerwa kwezvinhu zvakabikwa uye mafuta acho pachawo. Izvo zvisina kuchena muzvigadzirwa zvinosanganisira SiO2, Fe2O3, Na2O, K2O, nezvimwewo, uye tsvina mumafuta S, P, Cl nemamwe macommunication. Tsvina idzi dzinonyudzwa munzvimbo dzekupisa kwepamusoro. Mukati meiyo refractory material, kemikari inoitika inoitika nerefractory lining matrix, zvichikonzera nhevedzano yekukuvadza kune refractory material. Kemikari inopindirana pakati pemvura yechikamu uye pamusoro peiyo refractory pakupisa kwakanyanya, pamwe nekupinda uye kukukurwa kwezvinhu zvinokuvadza senge alkali munyu, zvinokonzeresa kuti iyo yekumusoro reaction layer ye refractory iparare uye kutsemuka kana yasangana neyakasanganiswa. mhedzisiro yekupisa uye mechanical stress.