- 29

- Oct

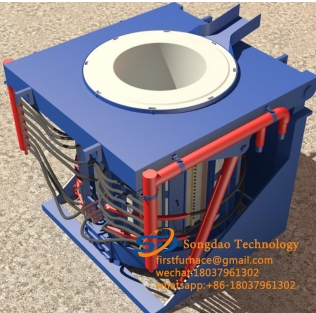

Izindlela ezi-5 ezinhle zokusebenzisa isithando somlilo se-induction!

Izindlela ezi-5 ezinhle zokusebenzisa isithando somlilo se-induction!

(1) Uma izinto ezibandayo zolayini lwesithando somlilo zincibilika, ukushaja kokuqala kungagcwaliswa kuphela ku-50% wobude obunqunu. Uma i-current yehla ku-voltage engakhuphuka ibe yinani elilinganiselwe, qhubeka uphakele i-crucible. (Lokhu kungenxa yokuthi ukumelana nokushaja okubandayo kuncane, okwamanje kukhulu, futhi i-voltage elawulayo inqunyelwe yamanje, ethinta okokufaka kwamandla). Kuya

(2) Phakathi nenqubo yokukhiqiza, akuvunyelwe ukugcwalisa noma ngisho nokudlula umlomo wesithando somlilo ngesikhathi esisodwa. Ngenxa yokuthi ukushaja ngenhla komkhawulo ongaphezulu wekhoyili yokungeniswa kunendawo enozibuthe ebuthakathaka, incike kakhulu ensimbi encibilikisiwe ngezansi ukuze idlulise ukushisa ukuze kushiswe, ngakho isivinini sokuncibilika siyahamba kancane. Ngesikhathi esifanayo, ngenxa yokuthi isithando somlilo asikwazi ukumbozwa, inani elikhulu lamandla okushisa lichithwa emlonyeni wesithando somlilo, okunciphisa ukukhiqiza. Kuya

Ngaphezu kwalokho, i-crucible engxenyeni engenhla ye-loop yokungeniswa kanye nolayini wesithando somlilo endaweni yokuhlangana ne-nozzle akulula ukuhlanganisa, isithando somlilo asiphelele, futhi i-sintering ayilungile, kodwa ukucindezelwa kokudlidliza komshini kukhulu kakhulu. , ngakho-ke ukuvuza kwesithando somlilo kungenzeka kulesi sigaba. Ngakho-ke, indawo yesisombululo ku-crucible kufanele ilawulwe ukuze iguqe ngengaphezulu ekugcineni kwekhoyili yokungeniswa. Kuya

(3) Nakuba insimbi encibilikisiwe esithandweni sokuncibilika sokungeniswa ingathululwa, ilungele ukuncibilikisa izinto ezihlukahlukene. Kodwa-ke, uma impahla ingashintshiwe, kungcono ukushiya uketshezi olusele esithandweni somlilo. Lokhu kungenxa yokuthi kunensimbi encibilikisiwe esithandweni somlilo, ukushaja okukhokhiswayo kuxhunywa kalula zibe izingcezu eziningi ezinkulu, futhi izingcezu zokushaja ezilodwa zizobe ziboshwe nge-arc futhi zishiselwe ndawonye ukuze zakhe ucezu olukhulu, ngaleyo ndlela andise izinga lokuncibilika. Isivinini se-arcing kanye nebhuloho phakathi kweshajethi eyodwa encane incike kubuningi. I-frequency iphansi, futhi isivinini se-lap welding siphansi (isizathu sokuthi kungani isithando somlilo semboni kufanele sishiye uketshezi olusele ukuze luncibilike).

Uma ingathululwanga, kunenani elincane lensimbi encibilikisiwe phansi kwesithando somlilo, futhi ukungalungi kokusebenzisa imvamisa ephansi kunganqotshwa kalula (imvamisa yesithando somlilo sokuncibilika siphansi kakhulu). Ngaphezu kwalokho, njengoba uketshezi olusele lunoshintsho oluncane lomthwalo ekuqaleni kwamandla, amandla aphezulu angaba okokufaka kusukela ekuqaleni, okungenani anganciphisa isikhathi sokuncibilika kokushaja kwensimbi. Kuya

(4) Lapho uncelisa, gwema indawo ephezulu yensimbi encibilikisiwe eyeqile umkhawulo wama-80% womthamo, ukuze ungabangeli izingozi lapho insimbi encibilikisiwe igcwala umlomo wesithando somlilo.

(5) Faka imali encane kuqala bese ukhuphula inani lenkokhelo.