- 15

- Sep

Complete set of induction heating equipment for quenching inner hole of balance shaft shell

Complete set of induction heating equipment for quenching inner hole of balance shaft shell

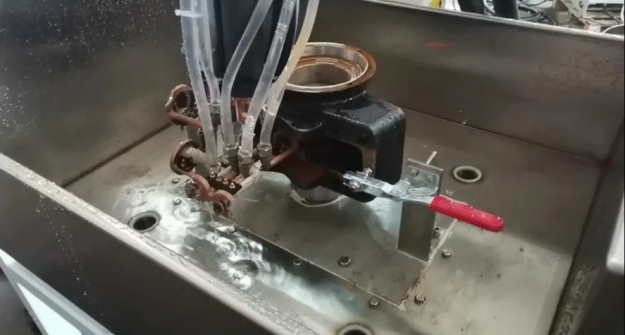

The complete set of induction heating equipment for quenching the inner hole of the balance shaft shell mainly includes the following 4 parts: 1. Intelligent induction heating IGBT power supply, one for two in time, high-frequency portable load; 2. 6-axis, 20KG manipulator; 3. Fixed platform and positioning Tooling (including manipulator positioning alarm system, quenching liquid collection water tank, positioning fixing system); 4. Circulating cooling system.

This set of equipment has continuous automatic production, manual production capabilities, and has automatic functions such as expansion and connection, automatic loading and unloading. The manipulator can meet the quenching requirements of all 17 holes of the workpiece, and the repeat positioning accuracy of the manipulator movement is ≤0.05mm.

The working process is as follows: the robot clamps the sensor fixture, which clamps two loads and two sensors at the same time to complete the quenching of two different diameter inner holes. The robot moves the positioning process for 3 seconds, and the heating and water spraying process totals 18 seconds. A total of 8 beats, 168 seconds to complete 8 holes with a φ26 arc surface; the robot rotates and moves the load sensor, the positioning process is 5 seconds, and the other φ35 hole is heated, and the heating water spray process is completed in 18 seconds; complete The total time for a single piece is less than 4 minutes.