- 30

- Oct

Abubuwan Da Ke Tasirin Rayuwar Sabis na Refractories a cikin Zuciyar Furnace

Abubuwan Da Ke Tasirin Rayuwar Sabis na Refractories a cikin Zuciyar Furnace

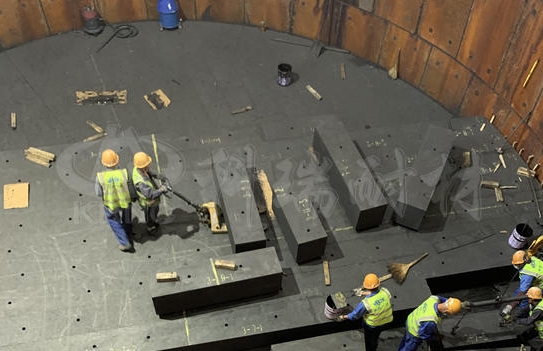

Bayan an kammala ginin wutar lantarki, daga sakawa zuwa ƙarshen sabis na tanderun, lokacin da kayan ya shiga cikin tsarin saukowa da iskar gas mai tasowa mataki na tsarin musayar zafi, tsakiyar da babba tanderun rufin rufin su ne refractories. a cikin yanayin lalacewa na dogon lokaci da zazzagewa, kuma ƙananan ɓangaren jikin tanderun shine tanderun murhu. An nutsar da rufin ƙasa a cikin narkakkar ƙarfe da sulke. Ciki na tanderun fashewar na ci gaba da kasancewa cikin matsanancin zafi da matsa lamba. Waɗannan abubuwan suna yin hulɗa kuma suna shafar rayuwar sabis na tanderun fashewar.

Akwai abubuwa da yawa waɗanda ke shafar rayuwar sabis na kayan daɗaɗɗen zuciya. Ya zuwa yanzu, ba a sami cikakkiyar fahimta da ra’ayi daya ba. Ra’ayoyi gama-gari da madaidaitan ra’ayi na iya taƙaita waɗannan abubuwan da ke da tasiri cikin nau’i biyu, wato, aikin jiki da zaizayar sinadarai.

1. Tasirin aikin jiki akan abin da ke damun zuciya:

(1) Damuwar zafi. Zazzabi na refractory aiki Layer a cikin hearth part da baƙin ƙarfe slag ruwa lamba batu ne kamar yadda high as 1350 ℃. Zazzabi mai sanyaya ruwa na sandar sanyaya da aka tuntuɓar Layer rufin zafi shine kawai 25 ~ 45 ℃. Bambancin zafin jiki na radial yana da girma, yana haifar da babban damuwa na thermal. Ƙarƙashin yanayin zafi mai tsayi da tsayin daka da yanayin hanya, damuwa mai zafi da sauran hulɗar jiki da sinadarai suna shafar juna, wanda ya haifar da lalacewa daban-daban kamar fadada zafin jiki da ƙaddamar da kayan da aka gyara, karaya, da ƙwanƙwasa.

(2) Ciki da shayarwa. A lokacin aikin tanderun fashewar, rufin murhu na murhu yana ci gaba da amsawa ga yaduwar narkakken ƙarfe da kuma tashi da faɗuwar matakin slag. A ƙarƙashin tasirin yanayin zafi mai zafi da matsanancin yashewa da lalacewa na dogon lokaci, juriya na juriya na ci gaba da raguwa, wanda ke shafar rayuwar sabis ɗin sa. Fatar fatalwar da aka kafa akan ma’aunin lamba-baƙin ƙarfe na iya faɗuwa a yayin da ake yin jujjuyawar yanayin tanderun. A wannan lokacin, kayan da ke jujjuyawa na rufin tanderun za a zazzage su kai tsaye kuma a lalata su ta hanyar ƙarfe da narkakken ƙarfe.

(3) Nauyin jiki. A lokacin amfani da fashewar tanderun, narkakken ƙarfen ya ci gaba da ƙara wa murhu da narkakkar ƙarfen da aka adana a cikin mataccen ƙarfen ƙarfe, gami da tasirin iska mai zafi mai zafi a cikin tanderun, wanda ya mamaye juna, ta yadda mai refractory. a kasan tanderun yana ɗauke da nauyi na jiki. . Don Layer bulo na carbon a mahaɗin murhu da ƙasan tanderun, waɗannan sojojin suna taka rawa wajen sassare. Ƙarfin ƙarfin tubalin carbon a zafin jiki shine 20-40MPa, kuma ƙarfin sassauƙa shine kawai 7-15MPa. Ƙarfi a babban yanayin zafi Lokacin da zafin jiki ya yi ƙasa da zafin jiki na al’ada, lokacin da matsa lamba yana kusa da iyakar ƙarfinsa, yana da sauƙi a karya ko samar da fasa. A wannan lokacin, ruwa na baƙin ƙarfe zai kutsa cikin ramuka da tsagewa. Kutsawa da yashewar baƙin ƙarfe.

(4) Yawan narkakkar baƙin ƙarfe. Yawancin kayan da ke jujjuyawa ya fi na narkakkar baƙin ƙarfe da yawa, kuma za a yi amfani da kayan da ke jujjuya zuwa sama a cikin narkakken ƙarfe. Ana saita ƙasan murhun gabaɗaya kusa da harsashi na tanderan tare da wani ɗan ƙaramin diamita, kuma ana amfani da extrusion kai tsaye da gogayya na refractory don raunana buoyancy. Duk da haka, lokacin da ƙarfin ya kai iyakar abin da ke da ƙarfi, zai haifar da raguwa ko ma karya kuma ya ci gaba da wahala. Tasirin buoyancy yana biye da lalacewa mai tsanani ko ma faɗuwa daga iyo.

2. Harin sinadari:

(1) Hot karfe carburizing lalata. Iron Alade shine maganin da ba shi da isasshen kuzari na ƙarfe-carbon narkakken ƙarfe. Abubuwan da ke cikin carbon na ƙarfe na alade ana kiyaye su gabaɗaya a 4.5% zuwa 5.4% yayin aikin samarwa. Abubuwan da ke cikin carbon yana da alaƙa da abubuwa kamar ƙarar wutar tanderu, matsin iska mai zafi da ƙarfin narkewa, kuma mafi girman Nawa bai bayyana ba. Sabili da haka, yayin da ake aiki da tanderun fashewar, halayen carburizing tsakanin narkakkar baƙin ƙarfe a cikin murhu da tubalin carbon yana faruwa lokaci zuwa lokaci, kuma coke da coal foda a cikin man za a iya yin carburized. Alamar dogon lokaci tana shafar tubalin carbon a cikin murhu. Narke asara da lalacewa.

(2) Redox dauki. A lokacin samar da iskar fashewar tanderu, nau’ikan nau’ikan haɓakar haɓakar iskar shaka suna faruwa a cikin murhu, kamar yadda ruwan iskar gas ya haifar da yayyowar ruwa a tuyere da bangon sanyaya, wanda zai haifar da iskar oxygenation na tubalin carbon. , yana haifar da asarar carbon ko ma datsewa, yana haifar da fasa. Ƙarfin tubalin carbon yana raguwa. Jerin halayen rage iskar shaka-rage halayen alkali kamar potassium, sodium, gubar, da zinc a cikin tanderun fashewar na iya haifar da sakin tubalin carbon, fasa zobe da sauran illa masu lalacewa.

Abubuwan lalata na jiki da na sinadarai suna ci gaba da faruwa a cikin murhu da kasan tanderun, kuma suna mu’amala da juna kuma suna lalata wutar lantarki da na kasa. Sabili da haka, lokacin zabar kayan haɓakawa a cikin murhu da ƙasa, abubuwan da ke sama yakamata su kasance daidai da takamaiman tanderu. Don tabbatar da rayuwar sabis, ya kamata a zaɓi kayan haɓakawa tare da ingantaccen aiki daidai.